Chery A11. Manual - part 140

Allowable Types of Snap Ring

Article No.

Thickness (mm)

015-1700381AA 2.8

015-170038AB 2.9

015-1700381AC 3.0

015-1700381AD 3.1

015-1700381AE 3.2

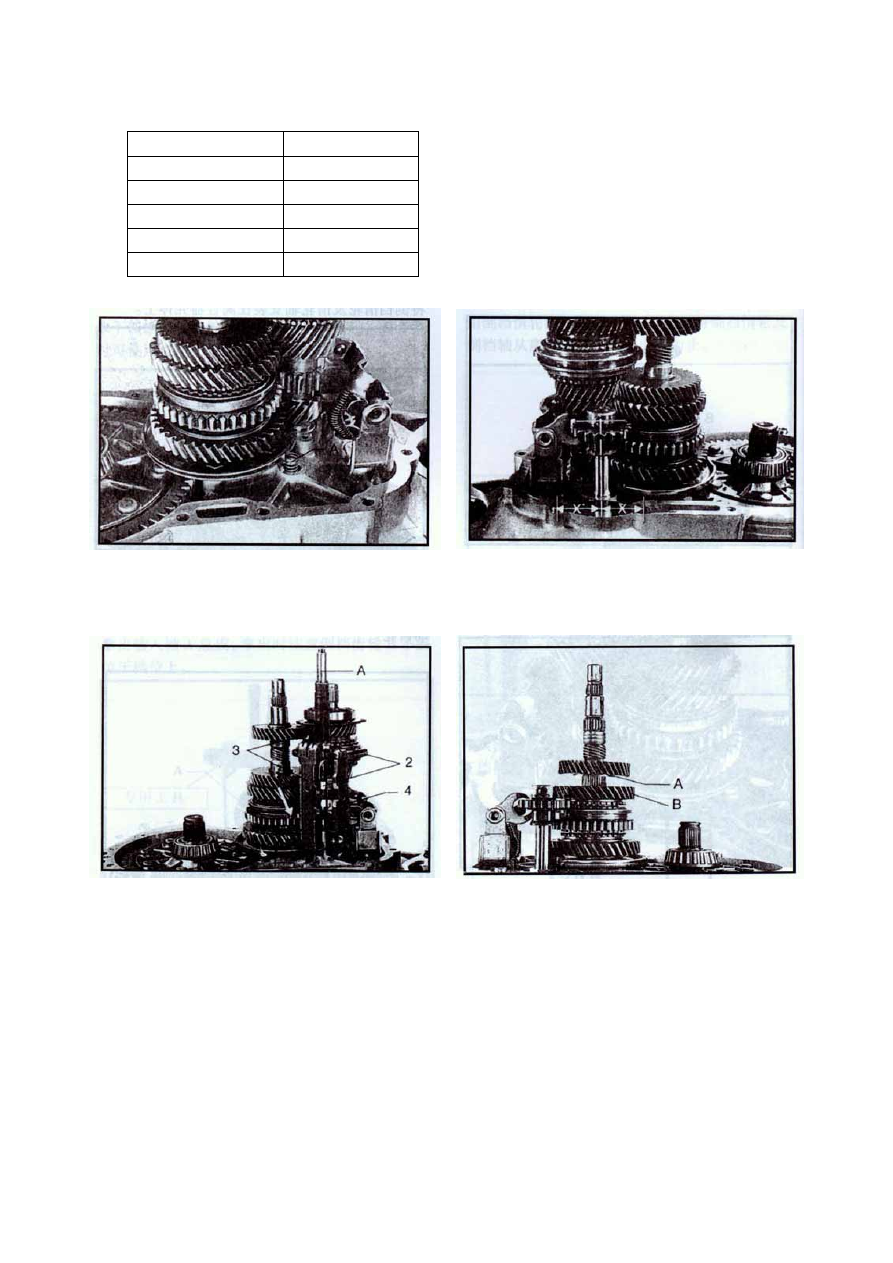

When mounting fork shaft, pay attention to putting the

counterpoise spring into the fork shaft hole of clutch

housing.

When mounting idler shaft, Value X should be equal.

Mount the fork assy. onto their correct positions

1— Gear-1 and gear-2 fork

2— Gear-3 and gear-4 fork

3— Gear-5 fork guide board and bushing

4— Reverse gear fork guide board

When mounting the rear shaft pump baffle A of input

shaft, notice the position A should be as indicated by

the figure. Put on new gaskets of fore and rear

housings, and then the transmission housing.

15