Haima S5 1.5T. Service Manual - part 4

Engine block 1A-45

Standard end gap:0.09~0.273mm

Maximum end gap:0.30mm

Thrust bearing’s size Thrust bearing’s thickness

Standard 3.205~3.255

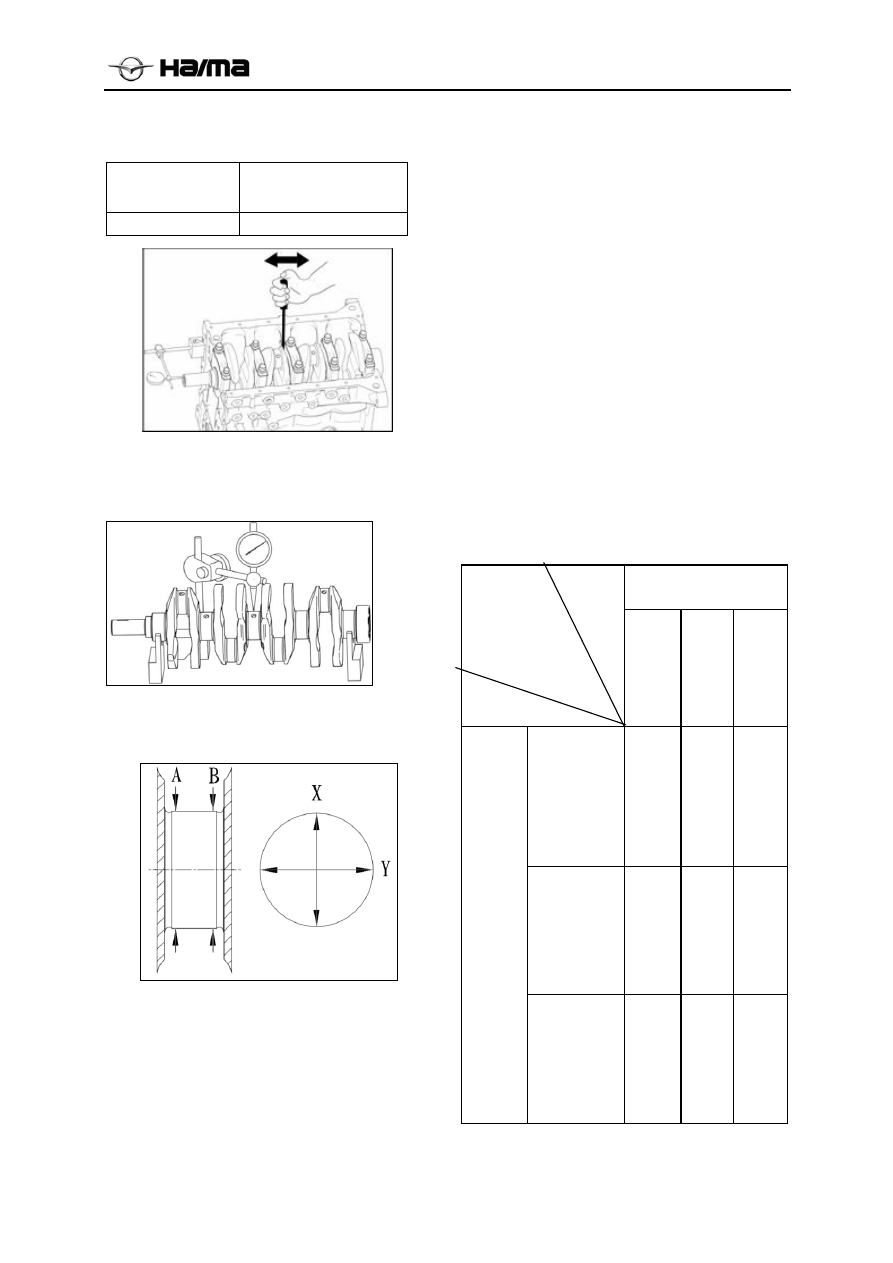

2. Measure the crankshaft’s radial run-out. If

necessary, replace the crankshaft.

Maximum radial circle run-out:0.03mm

3. Respectively at A and B point along X and Y

direction, measure the journal diameter. If

necessary, replace the crankshaft.

Main journal

Diameter(mm)

Standard

45.982~46.000

Crank pin

Diameter(mm)

Standard

43.979~44.000

4. Measure the main journal’s clearance

according to method below.

(1). Remove all oil on the crankshaft journal and

bearing seat’s internal surface.

(2). Make the plastic gauge match the bearing

width and then put it on the top of journal,

keeping parallel with the axial line.

(3). Mount the main bearing cover (see the main

bearing cover mounting part).

(4). Dismantle the main bearing cover bolt, and

slowly take off the main bearing cover (see

main bearing cover mounting part).

(5). Use the plastic gauge scale to measure the

widest point on the plastic gauge’s extruded

part, and then calculate out the journal

clearance. If the clearance exceeds the

maximum value, replace the crankshaft and

corresponding bearing bush to ensure the

standard clearance.

Standard clearance:

0.018~0.036mm

Maximum clearance: 0.1mm

Crankshaft bearing matching table mm

Crankshaft main journal

diameter

Crankshaft

bearing thickness

Cylinder

1:φ

45.994

~φ

46.000

2:φ

45.988

~φ

45.994

3:φ

45.982

~φ

45.988

1:φ

50.000

~φ

50.006

1#

1.988~

1.991

2#

1.991~

1.994

3#

1.994

~

1.997

2:φ

50.006

~φ

50.012

2#

1.991~

1.994

3#

1.994

~

1.997

4#

1.997

~

2.000

Cy

lin

de

r

m

ai

n

be

ari

ng

ho

le

di

a

m

ete

r

3:φ

50.012

~φ

50.018

3#

1.994~

1.997

4#

1.997

~

2.000

5#

2.000

~

2.003