Haima S5 1.5T. Service Manual - part 2

Engine block 1A-13

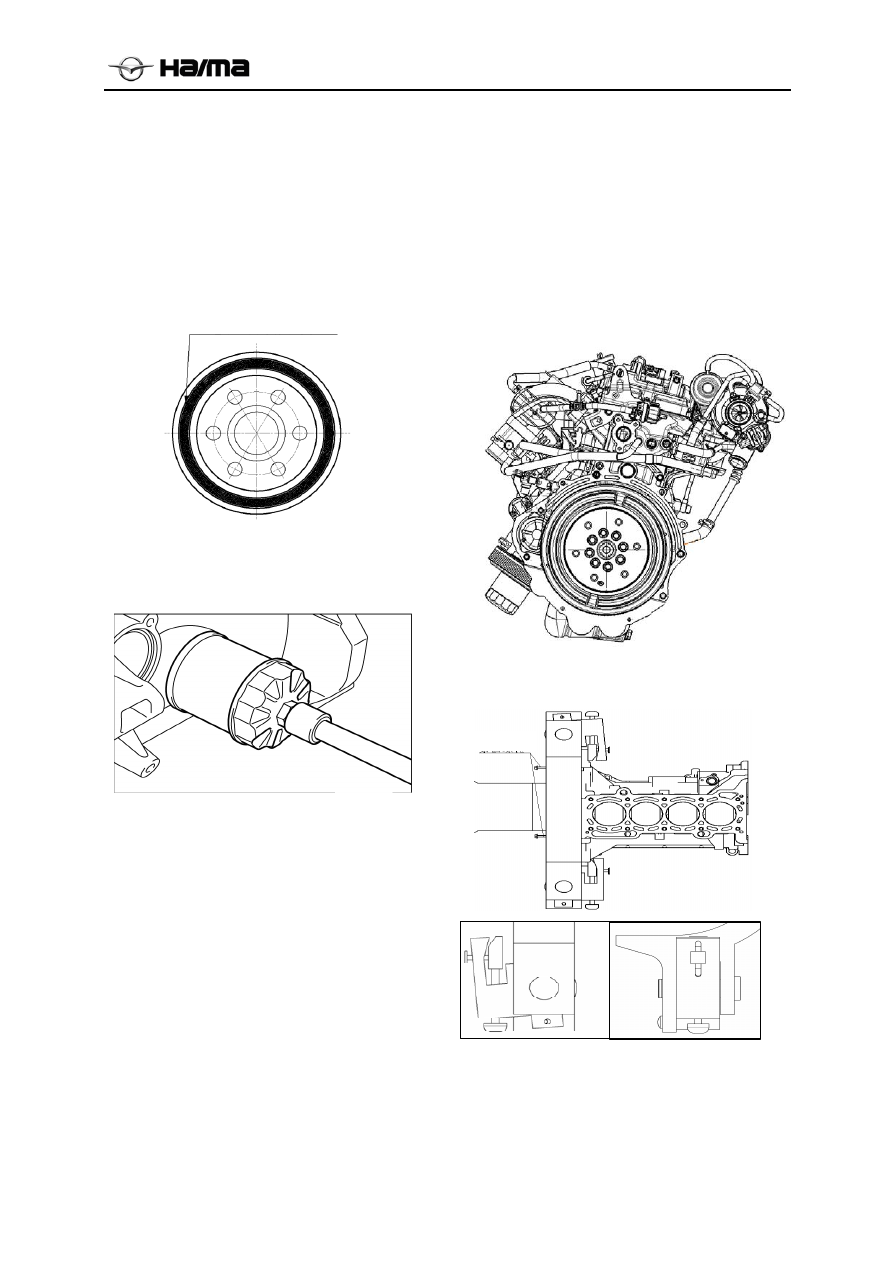

1.2.5 Replacement of Oil Filter

1. Dismantle the oil filter with special tools.

2. Rub and clean the new oil filter with a clean

cloth.

3. Smear clean oil onto the new oil filter’s

O-ring.

4. Mount the oil filter with special tools

Tightening torque:

14.0~16.0N·m{1.42~

1.63kgf·m}.

5. Start the engine and inspect if there is leakage.

Inspect the oil level and check if oil adding is

needed (see Inspection of Engine Oil).

Others

Other inspection and maintenance like power

generator inspection and starter inspection etc can

be conducted on the complete vehicle. See this

manual and corresponding complete vehicle

maintenance manual for processing procedures.

1.3 Application of Engine

Maintenance Platform

1.3.1 Mount the Engine onto

Maintenance Platform

1. Lift the engine, and align the cylinder body’s

pin hole to the maintenance platform’s

mounting dowel pin to mount the engine(see

the figure).

2.

Mount the work fixture according to the

figure and lock it.

3. Adjust the fixing bolt to appropriate place and

prevent the engine mounting from getting

loose.

4. Pour the engine oil into specified vessel.

Smear clean oil onto the

new oil filter’s O-ring.

Fixing bolt