Haima M3. Service Manual - part 9

MF515L Transmission

1H-13

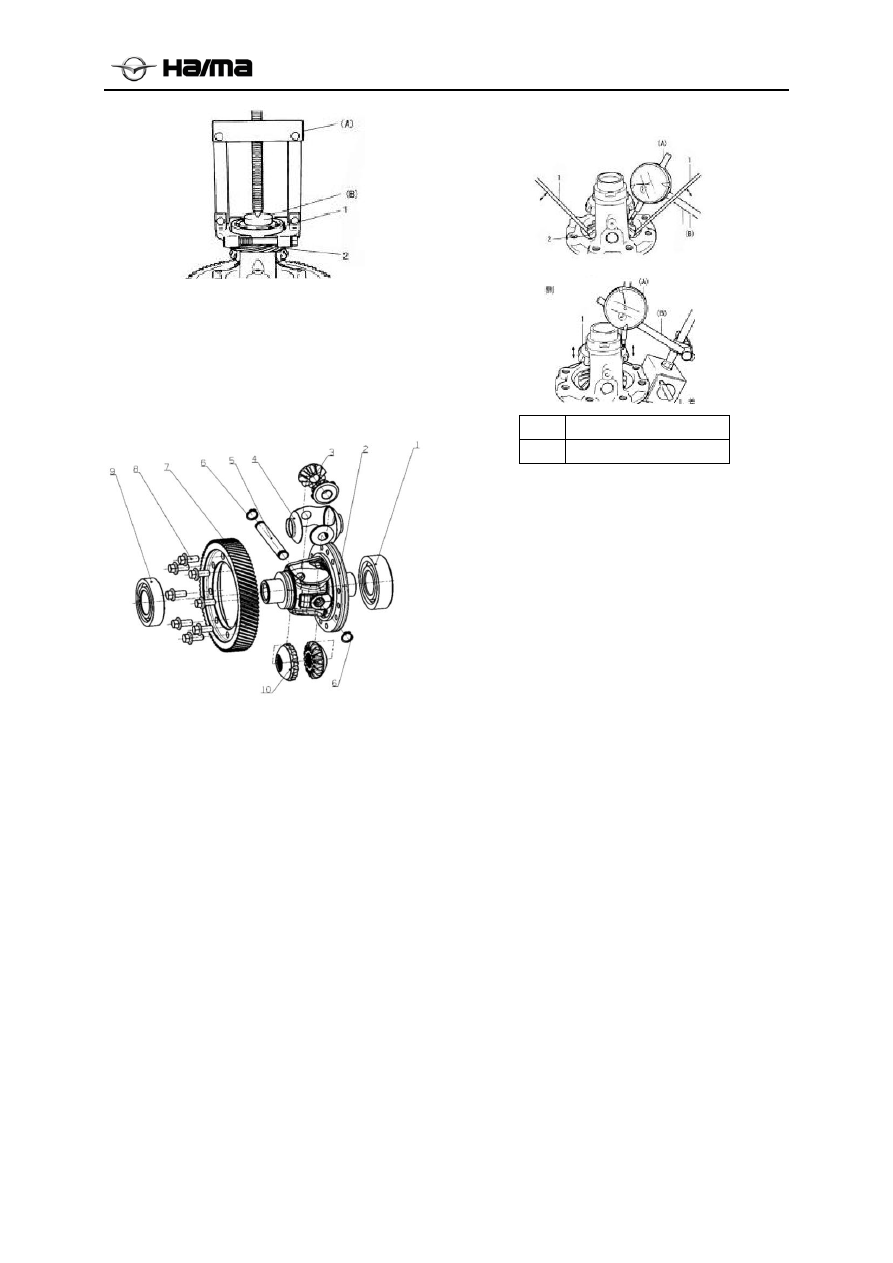

Differential Unit Adjustment and Remounting

Dismantling shall be determined according to the

fault denoted in preceding content. After the

dismantling, use naked eyes to inspect if the parts

have problems, and prepare spare parts for the

replacement and remount these parts, during

which make sure all parts are clean.

1.Differential left bearing 2.Differential housing

3. Planet gear 4. Differential spacer 5.Planet

gear shaft 6.Planet gear shaft

7. Main reduction gear 8.Differential bolt

9.Differential right bearing 10.Differential half

shaft

1) Mount the differential gear according to the

illustration and follow method below to

measure the differential’s pushing clearance.

Special tools(A): dial gauge;(B): magnet base

differential gear pushing clearance: 0.03-0.40mm

Left side: use the soft bench clamp to clamp the

differential assembly, and also insert the dial feeler

gauge’s measuring terminal onto the gear’s upper

surface. Use two screwdrivers to move the gear

upwards and downwards, in addition to reading the

gauge feeler gauge’s pointer travel.

Right side: use similar method and insert the dial

feeler gauge’s measuring terminal onto the gear’s

shoulder. Use the hand to move the gear upwards

and downwards and read the feeler gauge’s

reading.

1 Screwdriver

2 Half

axle

gear

2) If the pushing clearance exceeds the specified

value, select appropriate thrust washer from the

following sizes for mounting, and inspect again

if specified gear clearance range has been met.

Thickness of thrust washers:0.9, 0.95, 1.0, 1.05,

1.15, and 1.2mm

3) Drive in the spring from right side till the pin

keeps even with differential housing surface.

4) Use special tool and hydraulic pressure to press

and mount the left bearing. Special tool:

bearing erector 6

5) Suspend the differential assembly onto left

bearing (see the figure) and follow the Step 4)

to press and mount the right bearing.

6) Use soft bench clamp to clamp the differential

assembly, mount main reduction gear, and then

use eight bolts to tighten the differential

assembly according to required torque.

Notice

Other bolts beyond requirements shall not be

used.

Tightening torque

(a):80-100N·m