Kubota tractor (BX25DLB-AU, LA240A, LA240A, AU-SG, BT602). OPERATOR'S MANUAL - part 21

53

HYDRAULIC UNIT

B

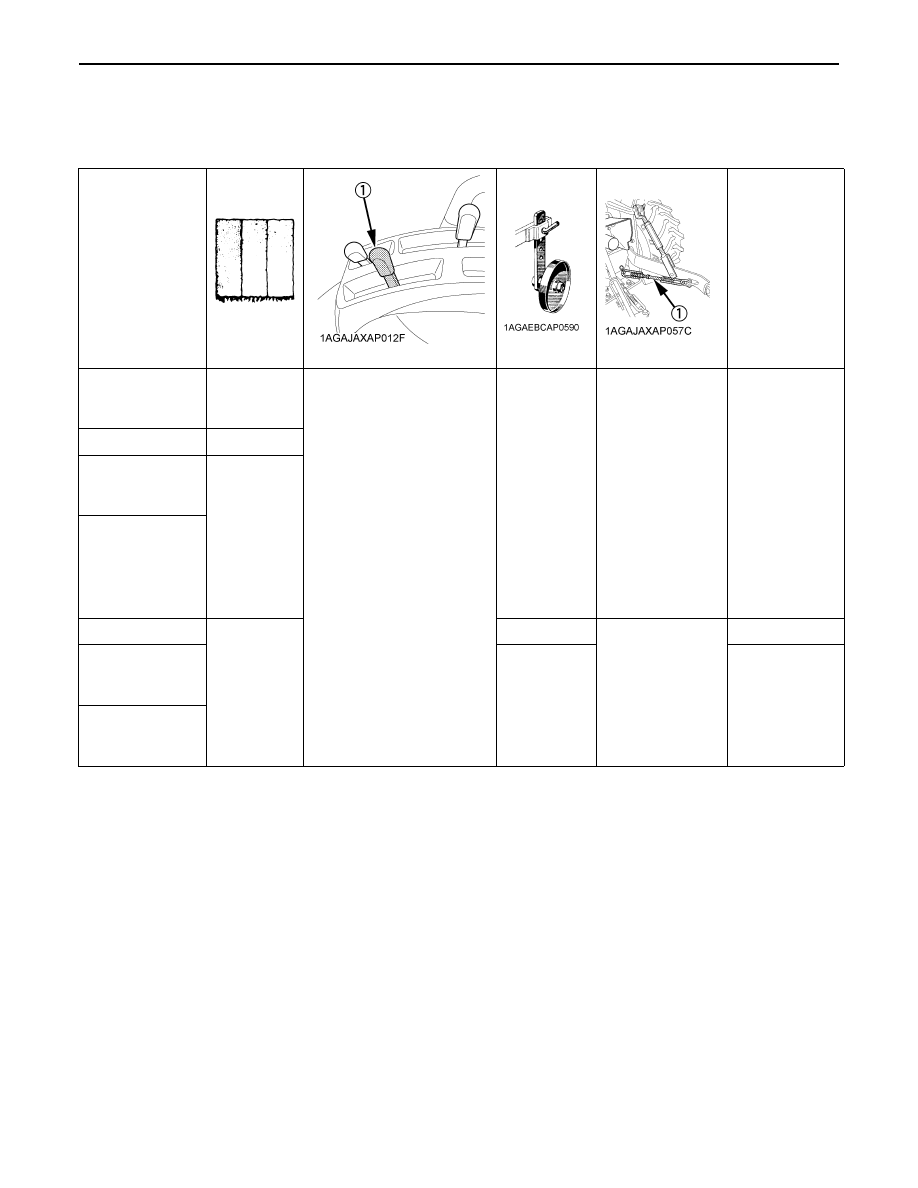

Hydraulic Control Unit Use Reference Chart

In order to handle the hydraulics properly, the operator must be familiar with the following. Though this information may not

be applicable to all types of implements and soil conditions, it is useful for general conditions.

Implement

Soil condition

(1) Hydraulic control lever

Gauge wheel

(1) Check chains

Remarks

Moldboard plow

Light soil

Medium soil

Heavy soil

Hydraulic control

YES/NO

Loose

Adjust the check

chains so that

the implement

can move 5 to 6

cm laterally.

Check chains

should be tight

enough to

prevent

excessive

implement

movement when

implement is in

raised position.

Disc plow

---

Harrower (spike,

springtooth, disc

type)

---

Sub-soiler......

Weeder, ridger.....

---

YES

Tighten

Earthmove, digger

scraper, manure

fork rear carrier....

YES/NO

For implements

with gauge

wheels, lower

the position

control lever all

way.

Mower (mid-and

rear-mount type)

Hayrake, tedder...