Kubota tractor (BX25DLB-AU, LA240A, LA240A, AU-SG, BT602). OPERATOR'S MANUAL - part 13

21

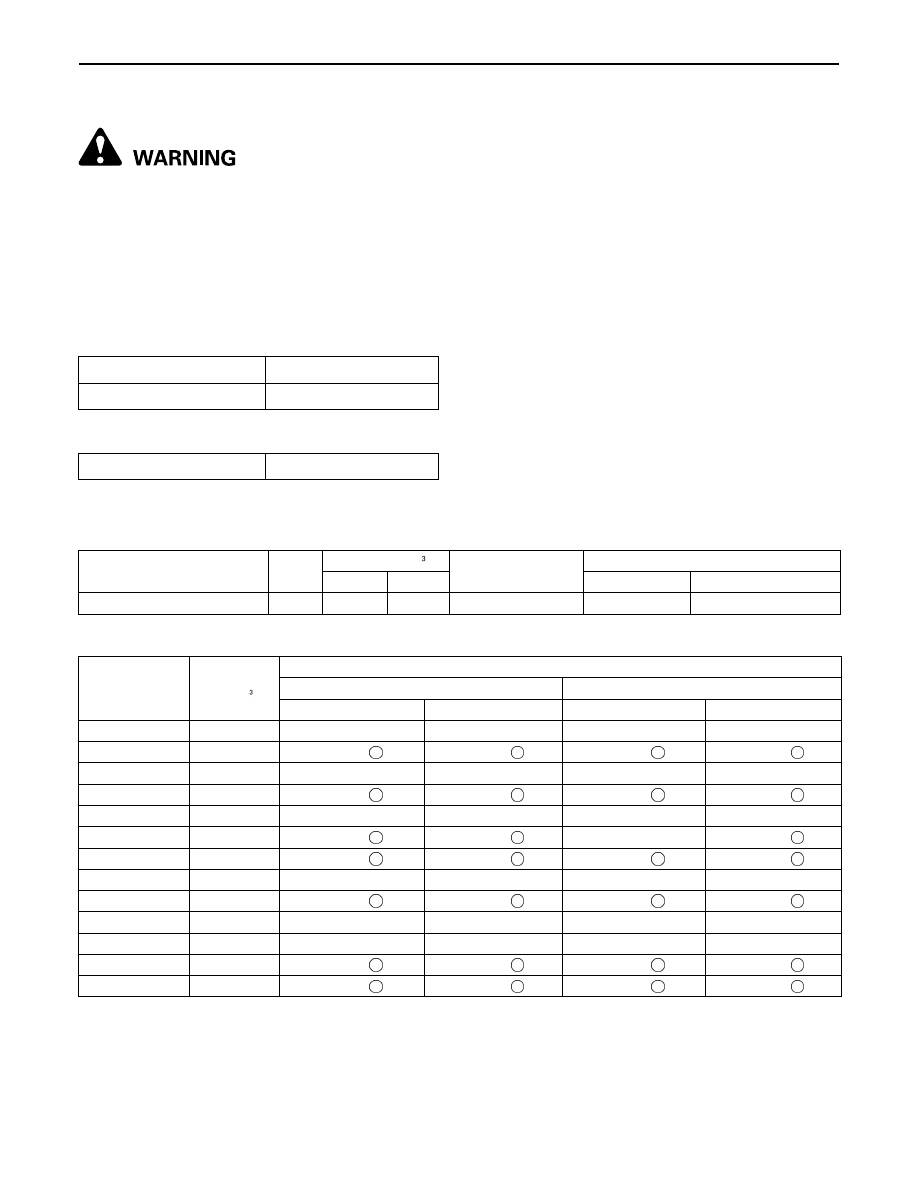

PRE-OPERATION CHECK OF THE LOADER

RATED OPERATING LOAD (SPILL GUARD MODEL ONLY)

To avoid personal injury or death:

A

Do not exceed ROL (Rated operation load).

A

Do not operate the loader without counter weight.

A

Do not exceed 10 km/h when travelling with load.

A

Use only tires approved by Kubota for loader use.

A

ROL is calculated with standard bucket. Optional attachments (4IN1 bucket etc.) will reduce ROL.

A

ROL is determined with the tractor static, on a hard level surface. Reduce load from the listed ROL if

operating on uneven or sloping terrain.

A

Remove the mid mount mower deck (if fitted) before operating the loader.

[With counter weight]

[With backhoe]

*Be sure to install the counter weight approved by

KUBOTA.

Rated operation load (ROL)

190 kg

Counter weight required

*170 kg

Rated operation load (ROL)

220 kg

Attachment

Width

(mm)

Capacity (m )

Attachment

Weight (kg)

Rated Operating Load (kg)

Heaped Struck

With Backhoe With counter Weight

LA240A AU-SG STD Bucket

1219

0.17

0.14

60

220

190

Material

DENSITY

(kg/m )

Standard Bucket

LA240A AU-SG with Backhoe

LA240A AU-SG with counter weight

Heaped Weight (kg) Struck Weight (kg) Heaped Weight (kg) Struck Weight (kg)

Blue Metal

1700

289 X

238 X

289 X

238 X

Clay Dry

1100

187

154

187

154

Clay Wet

1600

272 X

224 X

272 X

224 X

Earth Dry

1070

182

150

182

150

Earth Moist

1630

277 X

228 X

277 X

228 X

Earth Wet

1250

213

175

213 X

175

Fertilizer

1089

185

152

185

152

Gypsum

2547

433 X

357 X

433 X

357 X

Lime

849

144

119

144

119

Sand Dry

1720

292 X

241 X

292 X

241 X

Sand Wet

1900

323 X

266 X

323 X

266 X

Water

1000

170

140

170

140

Wheat

769

131

108

131

108