Snowmobile Polaris Turbo IQ LXT (2014 year). Manual - part 32

131

MAINTENANCE

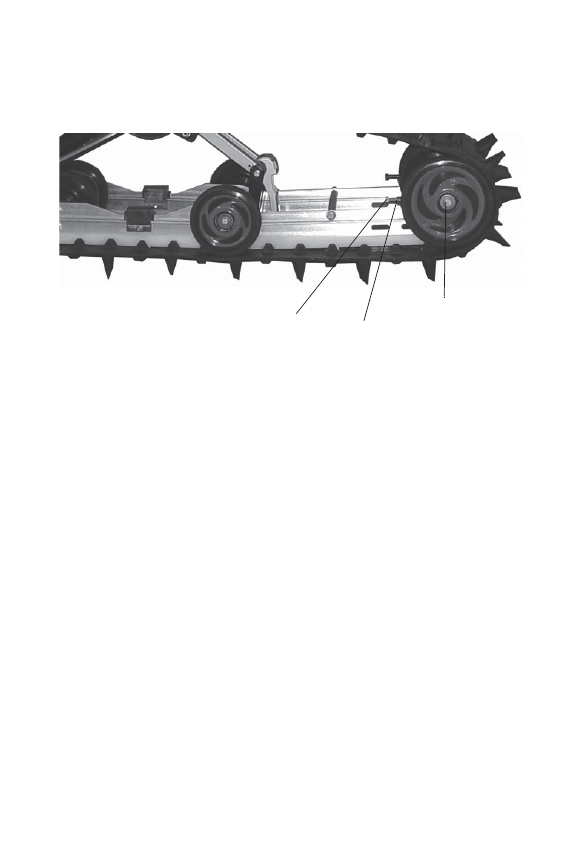

Track Tension

4. Check for specified slack between the wear surface of the track clip

and the plastic rail slide.

If the track needs adjustment:

5. Loosen the rear idler shaft bolt.

6. Loosen the lock nuts.

7. Tighten or loosen the track adjusting screws as necessary to provide

equal adjustment on both sides of the track.

8. Repeat the measurement on the other side of the track.

Tip: Check more frequently when the snowmobile is new.

9. Start the engine and slowly rotate the track at least five revolutions.

Let the track come to a stop (do not apply brakes).

10. Check track alignment (see page 132) and adjust as necessary.

11. Tighten the lock nuts.

12. Tighten the idler shaft bolts. Torque to 35 ft. lbs. (47.5 Nm).

Idler Shaft

Bolt

Adjusting

Screw

Lock

Nut