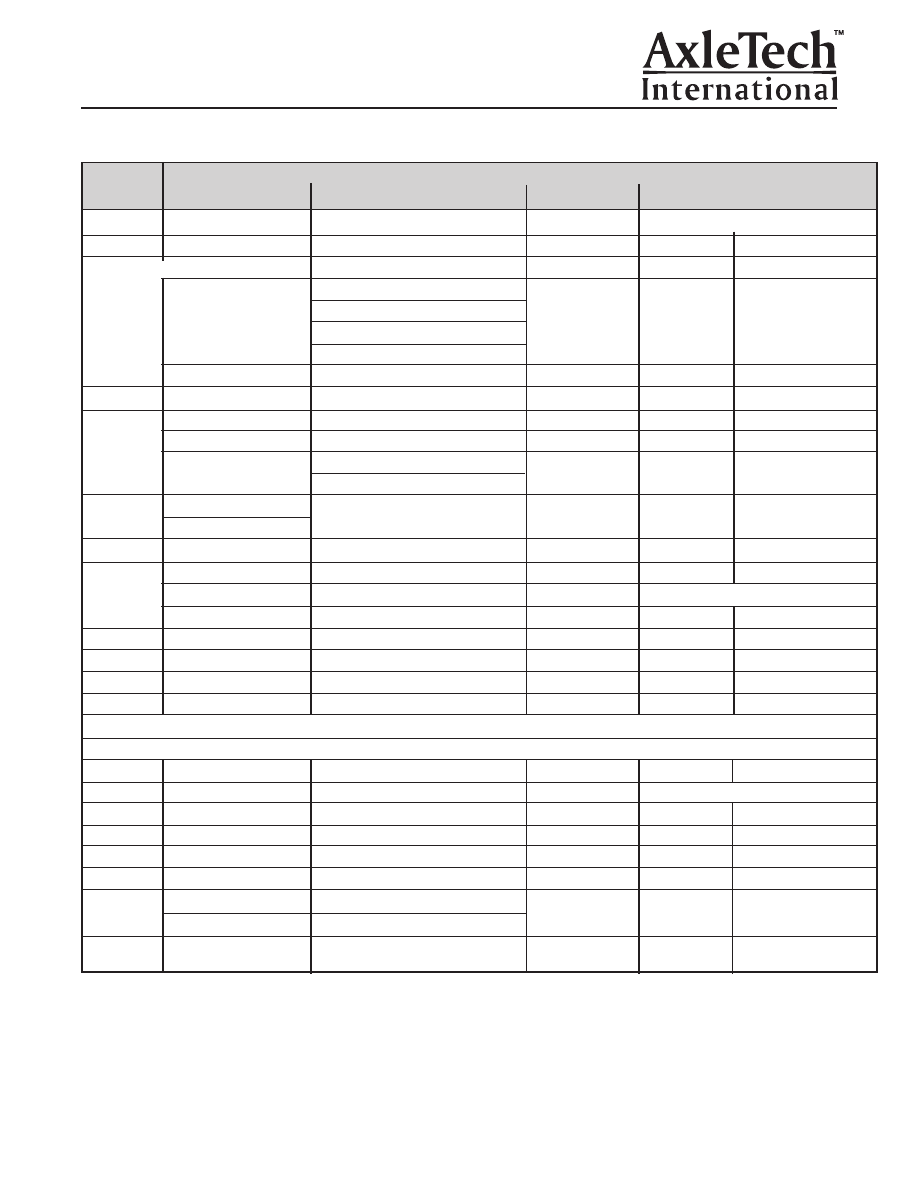

Challenger Terra Gator 3244 Chassis. Manual - part 101

THREAD

TYPE

LOCATION

THREAD

TORQUE N•m (lb-ft)

SPEC

COMPOUND [1]

nominal

range

FASTENERS

capscrew L16 Allen-head Wheel Sup: Cover-Wheel Driver

medium-strength

38.3 (28.2)

33.5 (24.7) – 43.1 (31.8)

Wheel Sup: Lock Plate-Wheel Nut

Wheel Sup: Wheel Driver-Wheel Hub

M8x1.25

capscrew L25 Allen-head

Planet: Spring Hsg-Axle Hsg

medium-strength

38.3 (28.2)

33.5 (24.7) – 43.1 (31.8)

HDL: Inlet Port-Carrier Hsg

capscrew L30 Allen Head Carrier: Bearing Cap (Adj. Ring Lock)

medium strength

33.0 (24.3)

28 (20.7) - 38(28)

M10x1.5

setscrew L16 socket-head

Planet: Pinion Shaft-Spider

medium-strength

27.0 (19.9)

23.0 (16.9) - 31.0 (22.9)

capscrew L45 hex-head

Carrier Pinion Cage-Carrier Hsg

medium-strength

132 (97.4)

119 (87.7) - 145 (107)

capscrew L70 hex-head

Carrier: Diff. Case-Diff. Case

STF 02-452

143 (105.5)

130 (96) - 155 (114)

M12x1.75

Trunnion: Adapter-Axle Hsg

capscrew L80 Allen-head

Trunnion: Bracket-Trunnion Shaft

0il

119 (87.8)

107 (78.9) - 131 (96.6)

capscrew L50 hex-head

M16x2

capscrew L65 hex-head

Carrier: Carrier Hsg-Axle Hsg

high-strength

328 (241.9)

295 (217.6) - 361 (266.3)

M16x1.5

capscrew L62 hex-head

Carrier: Hypoid Gear-Diff. Case

medium-strength

350 (258)

315 (232) - 385 (284)

capscrew L140 hex-head Wheel Sup: Spindle-Axle Hsg

medium-strength

509 (375.4)

458 (337.8) - 560 (413.1)

M18x1.5

stud L170

Wheel Sup: Spindle-Axle Hsg

medium-strength

engage all threads

nut

Wheel Sup: Spindle-Axle Hsg

oil

412 (303.9)

371 (273.6) - 453 (334.1)

M20x2.5

capscrew L120 hex-head Carrier: Bearing Cap-Carrier Hsg

oil

485 (358)

430 (317) - 540 (398)

M22x1.5

nut-jam

Carrier: Hypoid Gear Thrust Screw

none

204 (150.5)

136 (100.3) - 272 (200.6)

M39x1.5

nut

Carrier: Yoke-Hypoid Pinion

oil

1,393 (1,027.5) 1,250 (922) - 1,535 (1132.2)

M150x2

nut

Wheel Sup: Wheel Brg-Spindle

oil

678 (500)

610 (449.9) - 746 (550.2)

PLUGS, FITTINGS

M12x1.5

fitting-Banjo

WDB:Banjo Fitting-Axle Hsg

oil

47.3 (34.9)

45.0 (33.2) - 49.5 (36.5)

M14x1.5

nut-fitting

WDB: Banjo Fitting-Tube

oil

finger tight + 1.5 turn

M22x1.5

port-inlet

WDB: Inlet Port-Axle Hsg

STF 02-452

37.8 (27.9)

34.0 (25.1) - 41.6 (30.7)

7/16”-20

screw-bleeder

WDB:Bleeder Screw-Axle Hsg

oil

23.5 (17)

20 (15) - 27 (20)

9/16”-18

fitting-Tee

WDB: Tee Fitting-Inlet Port

oil

35.7 (26.3)

34.0 (25.1) - 37.4 (27.6)

11/16”-16

nut-fitting

WDB: Tee Fitting-Tube

oil

42.0 (30.9)

40.0 (29.5) - 44.0 (32.5)

plug-fill

Hsg: Fill Plug

1 1/16”-12

plug-drain

Hsg: Drain Plug

oil

93 (68.6)

79 (58.3)

-

107 (78.9)

3/8-18 NPSF

breather

Top of Housing Breather

sealant-RTV or

28 Minimum

Permatex #51

[1] Thread compounds =

Medium-strength: Loctite #241/242/243, Three Bond #1334

High-strength: Loctite #271/273, Three Bond #1305

STF 02-452: Loctite 680

Sealants: Loctite Ultra Grey RTV, Permatex #51

Torque conversion factors

1N•m = 0.7376 lb-ft

1N•m = 10.20 kgf.cm

TORQUE TABLE

Section 6

Torque

Page 46