Challenger Terra Gator 3244 Chassis. Manual - part 27

627333-A

3-21

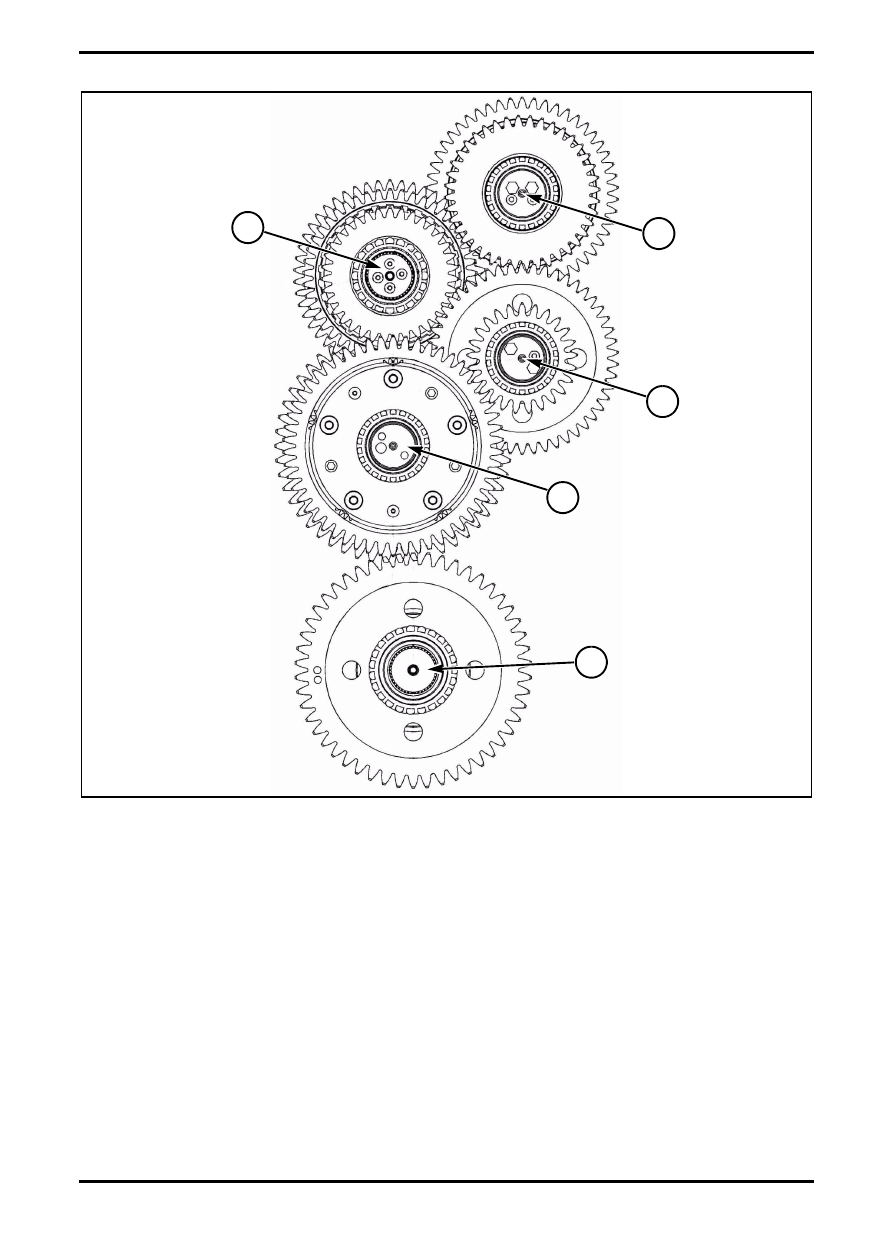

Transmission and Solenoids

Front view Transmission

1. Input Shaft;

7. Intermediate Shaft;

13. Ouput Shaft;

18. Transfer Shaft;

19. Reverse Shaft

Power flow for reverse gears only involves the clutches

on the shaft:

•

Reverse Shaft (19);

•

Output Shaft (13).

The different solenoids resembles the different clutches.

When a combination of solenoids is engaged, the

specific gear will be set.

Each gear has its own combination of solenoids. No

more than two clutches are engaged at the time. Also,

no more than one clutch is engaged at the time on any

shaft. The different combinations of solenoids is

regulated by the TCU.

For the reverse gear, input shaft (1) is used only to

transfer power flow through gear (10). For reverse

gears, intermediate shaft (7) is used only to transfer

power flow through gears (8), (11) and (15). This gear

are permanently splinted to the shafts. The gears will

always rotate with the shaft.

FIG. 20

Q000062S

18

13

7

19

1