Challenger Terra Gator 3244 Chassis. Manual - part 25

627333-A

3-13

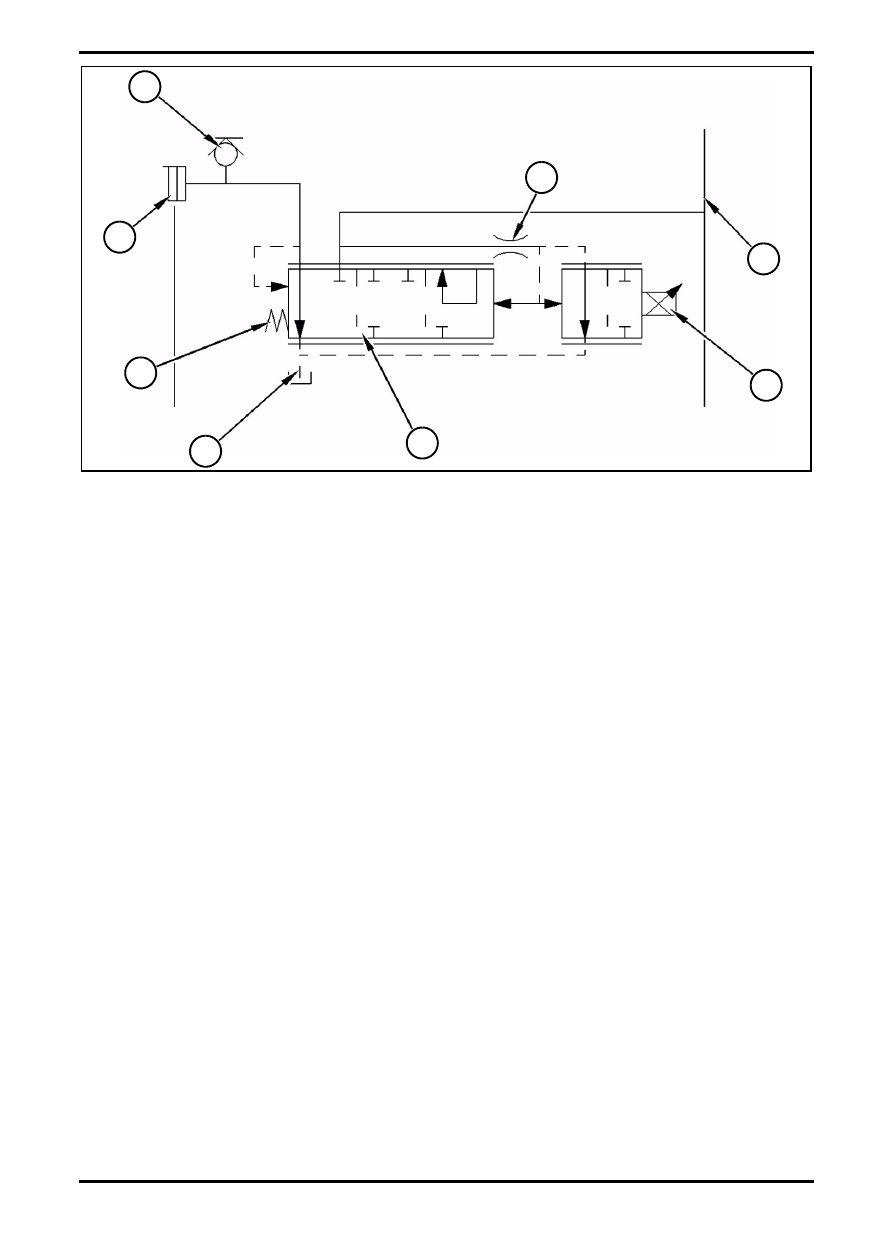

Transmission and Solenoids

Schematic of modulating valve (transmission)

1. Modulating Valve (Transmission);

2. Test Port;

3. Transmission Clutch;

4. Spring;

5. Line to Sump;

6. Spool Orifice;

7. Charge Pressure Oil;

8. Solenoid.

Modulating valve (1) is controlled by transmission

electronic control module (ECM). The modulating valve

is used by the transmission ECM to directly modulate

the oil pressure that is sent to each of the nine

individual transmission clutches.

When the operator selects a direction or when the

operator selects a speed, the transmission ECM sends

a pulse width modulated signals in order to vary the

current to solenoid (8).

The distance that is travelled by the solenoid plunger is

proportional to the electrical current that is sent to the

solenoid. The position of the solenoid plunger controls

the oil pressure the is sent to transmission clutch (3).

When the transmission ECM sends the maximum

programmed current to the modulating valve, the

pressure in the transmission clutch will be at the

maximum desired pressure. When no current is sent to

the modulating valve, the oil pressure in the

transmission clutch will be zero.

FIG. 13

Q000038S

2

3

4

5

1

8

7

6