TM 10-8400-203-23&P. Manual - part 13

TM

10-8400-203-23&P

0011

SKI REPAIR – CONTINUED

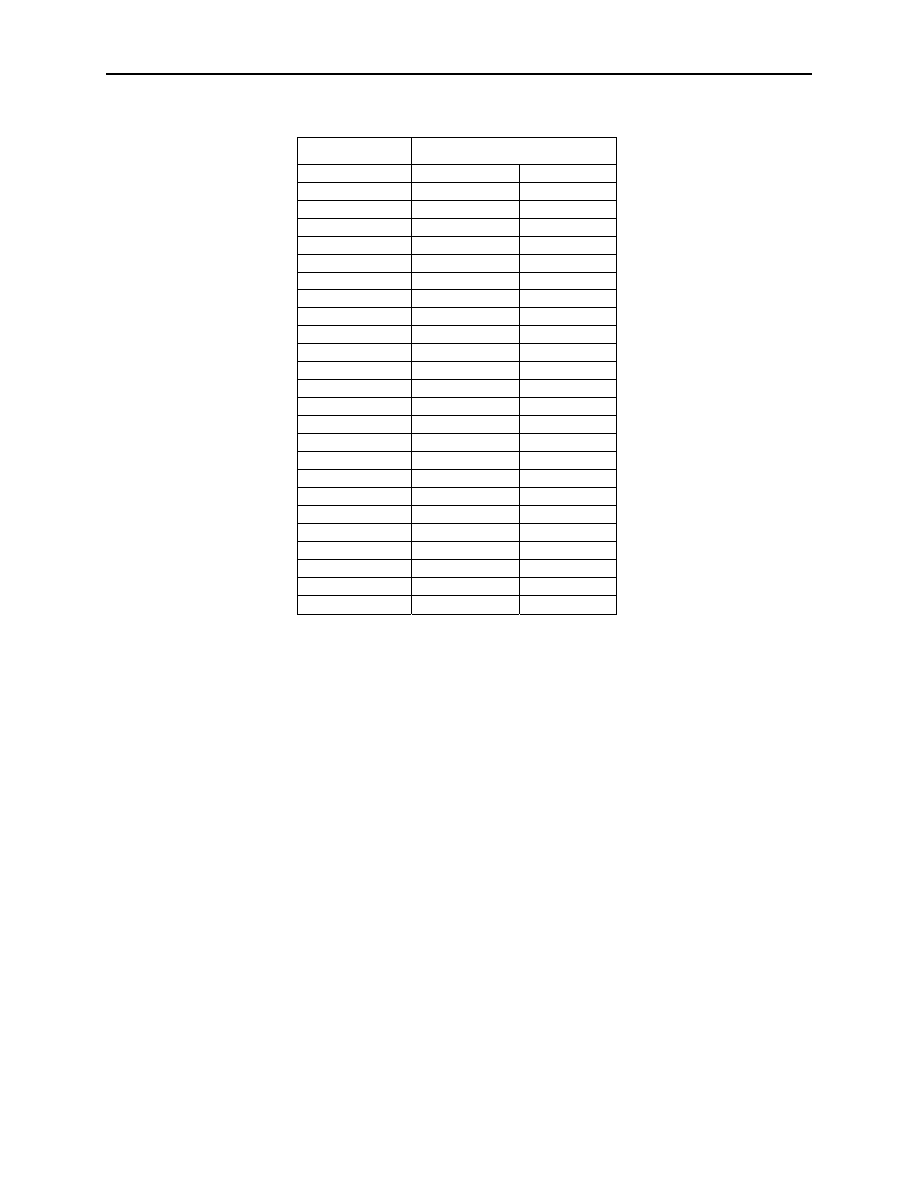

Table 1. Ski Mid Point Chart.

SKI LENGTH

HALF LENGTH

cm

cm

in

120

60.0

23 5/8

130

65.0

25 5/8

140

70.0

27 5/8

150

75.0

29 1/2

160

80.0

31 1/2

165

82.5

32 1/2

170

85.0

33 1/2

175

87.5

34 1/2

178

89.0

35

180

90.0

35 3/8

183

91.5

36

185

92.5

36 3/8

188

94.0

37

190

95.0

37 3/8

193

96.5

38

195

97.5

38 3/8

198

99.0

39

200

100.0

39 3/8

203

101.5

40

205

102.5

40 3/8

208

104.0

41

210

105.0

41 3/8

213

106.5

42

215

107.5

42 3/8

4. In mounting the toe piece, ensure that it is centered with the long axis of the ski.

NOTE

Swivel point of toe piece at midpoint.

8 in. from swivel point of toe piece to center of rear of front throw (large), 7 in. from swivel

point of toe piece to center of rear screw of front throw (small) 8 1/4 from swivel point of

toe piece to front screw of downhill cable guide Forward edge of heel plate even w/center

of downhill cable guide if heel plate is Iarge (2½” x 2¼”); 1” further rearward if small heel

plate (1¼” x 2¼”)

To determine a large front throw from a small front throw, measure from the front

mounting holes (those nearest the tip of the ski) to the back end of the lever in the closed

position. This distance is approximately 5 ½ inches for the large throw and 4 ½ inches for

the small throw.

5. Use the toe piece, front throw, and cable guides (side hitches) as templates in marking holes to be

drilled. Locate the binding parts as shown in Figure 2.