Yamaha XV19SW(C), XV19W(C), XV19MW(C), XV19CTSW(C), XV19CTW(C), XV19CTMW(C). Service Manual - part 27

ELECTRICAL COMPONENTS

7-76

cal system, cause the lighting and ignition

systems to malfunction and could possibly

cause a fire.

▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲ ▲▲▲

▲

▲▲▲

4. Install:

• Rider seat

Refer to “GENERAL CHASSIS” on page 4-1.

EAS28030

CHECKING AND CHARGING THE BATTERY

WARNING

EWA13290

Batteries generate explosive hydrogen gas

and contain electrolyte which is made of poi-

sonous and highly caustic sulfuric acid.

Therefore, always follow these preventive

measures:

• Wear protective eye gear when handling or

working near batteries.

• Charge batteries in a well-ventilated area.

• Keep batteries away from fire, sparks or

open flames (e.g., welding equipment,

lighted cigarettes).

• DO NOT SMOKE when charging or han-

dling batteries.

• KEEP BATTERIES AND ELECTROLYTE

OUT OF REACH OF CHILDREN.

• Avoid bodily contact with electrolyte as it

can cause severe burns or permanent eye

injury.

FIRST AID IN CASE OF BODILY CONTACT:

EXTERNAL

• Skin — Wash with water.

• Eyes — Flush with water for 15 minutes and

get immediate medical attention.

INTERNAL

• Drink large quantities of water or milk fol-

lowed with milk of magnesia, beaten egg or

vegetable oil. Get immediate medical atten-

tion.

CAUTION:

EC1D71020

• This is a sealed battery. Never remove the

sealing caps because the balance between

cells will not be maintained and battery per-

formance will deteriorate.

• Charging time, charging amperage and

charging voltage for an MF battery are dif-

ferent from those of conventional batteries.

The MF battery should be charged accord-

ing to the instructions for the charging

method. If the battery is overcharged, the

electrolyte level will drop considerably.

Therefore, take special care when charging

the battery.

NOTE:

Since MF batteries are sealed, it is not possible

to check the charge state of the battery by mea-

suring the specific gravity of the electrolyte.

Therefore, the charge of the battery has to be

checked by measuring the voltage at the battery

terminals.

1. Remove:

• Rider seat

Refer to “GENERAL CHASSIS” on page 4-1.

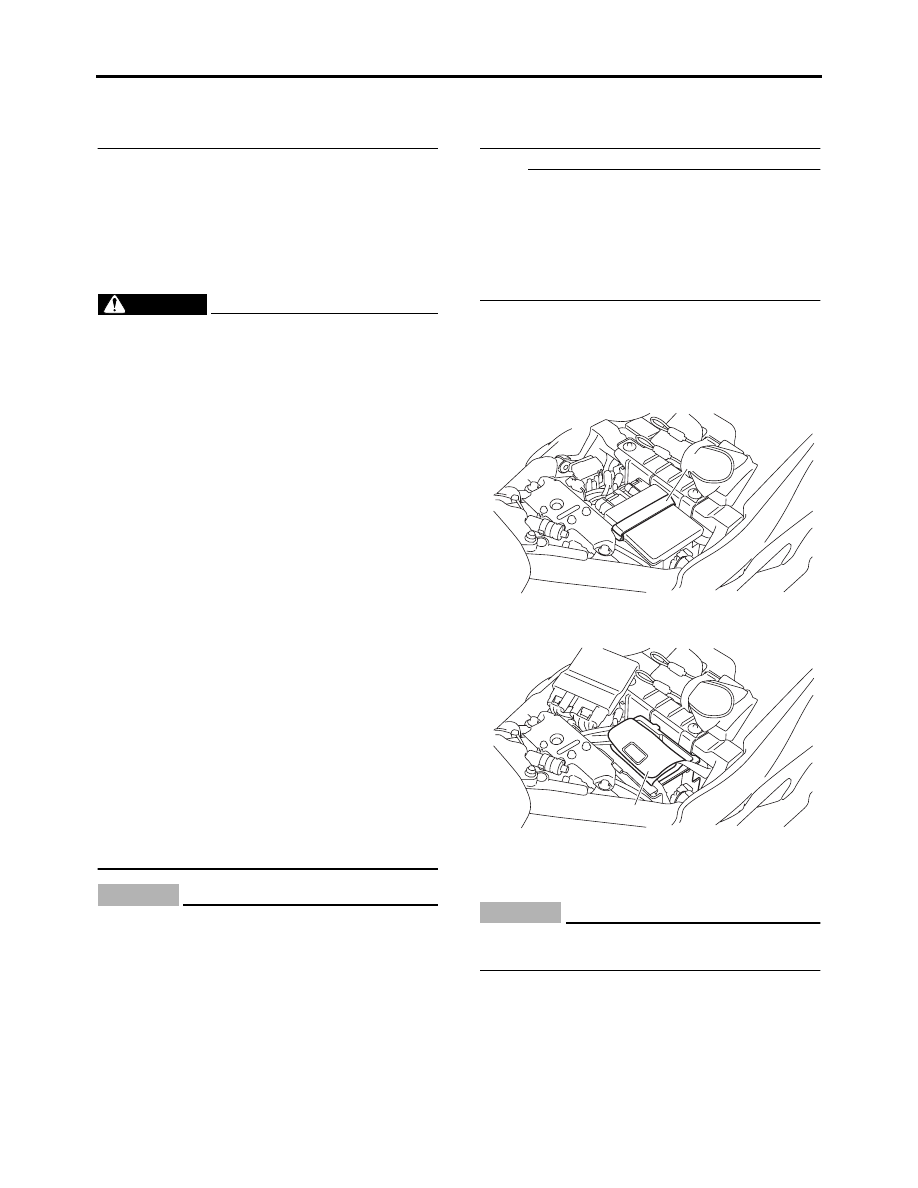

2. Remove:

• ECU band “1”

3. Remove:

• Coupler tray “1”

4. Disconnect:

• Battery leads

(from the battery terminals)

CAUTION:

ECA13640

First, disconnect the negative battery lead

“1”, and then positive battery lead “2”.

1

1