Yamaha XV19SW(C), XV19W(C), XV19MW(C), XV19CTSW(C), XV19CTW(C), XV19CTMW(C). Service Manual - part 15

CAMSHAFTS

5-16

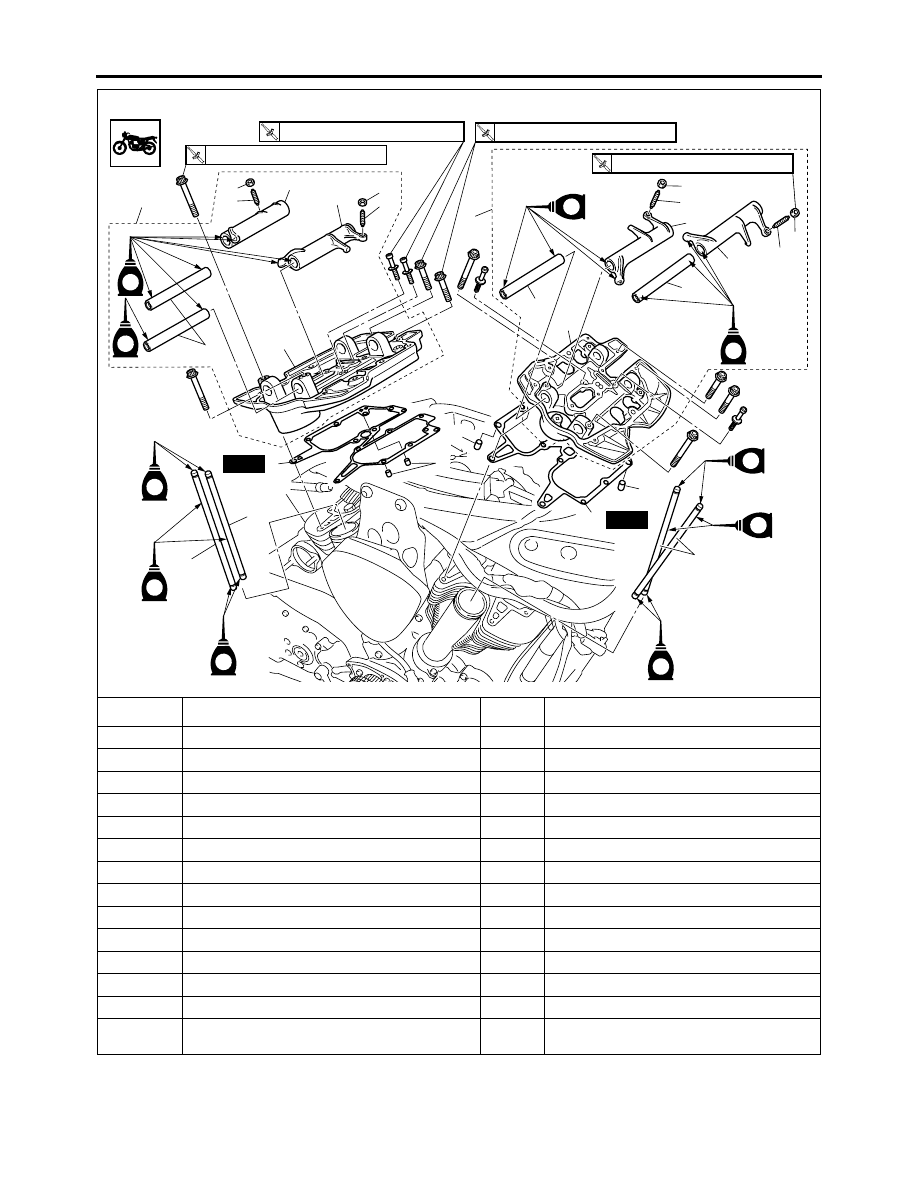

Removing the push rods and rocker arms

Order

Job/Parts to remove

Q’ty

Remarks

1

Rear rocker arm base assembly

1

2

Front rocker arm base assembly

1

3

Rocker arm base gasket

2

4

Dowel pin

4

5

Pull rod 1

3

l = 286.5 mm (11.280 in) pink painting

6

Pull rod 2

1

l = 288.5 mm (11.358 in) sky blue painting

7

Rocker arm shaft

4

8

Rocker arm 1

2

9

Rocker arm 2

2

10

Locknut

4

11

Adjusting screw

4

12

Rear rocker arm base

1

13

Front rocker arm base

1

For installation, reverse the removal proce-

dure.

E

E

E

E

E

E

E

E

E

10

11

8

10

11

9

7

6

5

12

3

4

4

10

11

8

7

10

11

9

7

5

4

3

New

New

1

2

13

R

10 Nm (1.0 m

•

kg, 7.2 ft

•

Ib)

T

R

24 Nm (2.4 m

•

kg, 17 ft

•

Ib)

T

R

20 Nm (2.0 m

•

kg, 14 ft

•

Ib)

E

R

24 Nm (2.4 m

•

kg, 17 ft

•

Ib)