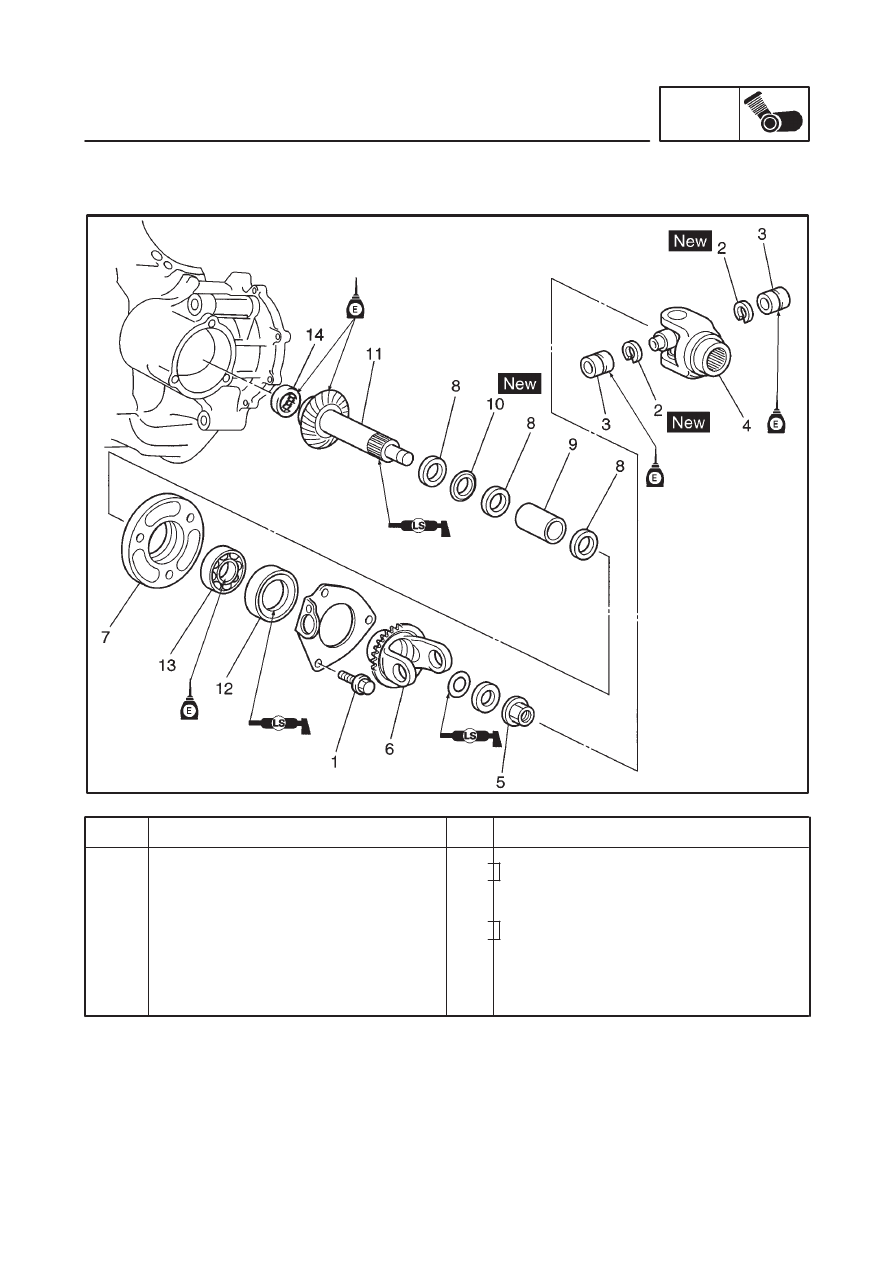

Yamaha XVS1100 (L). Service Manual - part 12

Order

Job name / Part name

Q’ty

Remarks

10

11

12

13

14

Collapsible collar

Middle driven shaft

Oil seal

Bearing

Bearing

1

1

1

1

For installation, reverse the removal

procedure.

Refer to “ASSEMBLING THE MIDDLE

DRIVEN SHAFT ASSEMBLY”.

Refer to “INSTALLING THE MIDDLE

GEAR ASSEMBLY AND ADJUSTING

THE BACKLASH”.

MIDDLE GEAR

ENG

4-74