Yamaha XVS1100 (L). Service Manual - part 10

4-42

CLUTCH

ENG

NOTE:

NOTE:

NOTE:

EAS00278

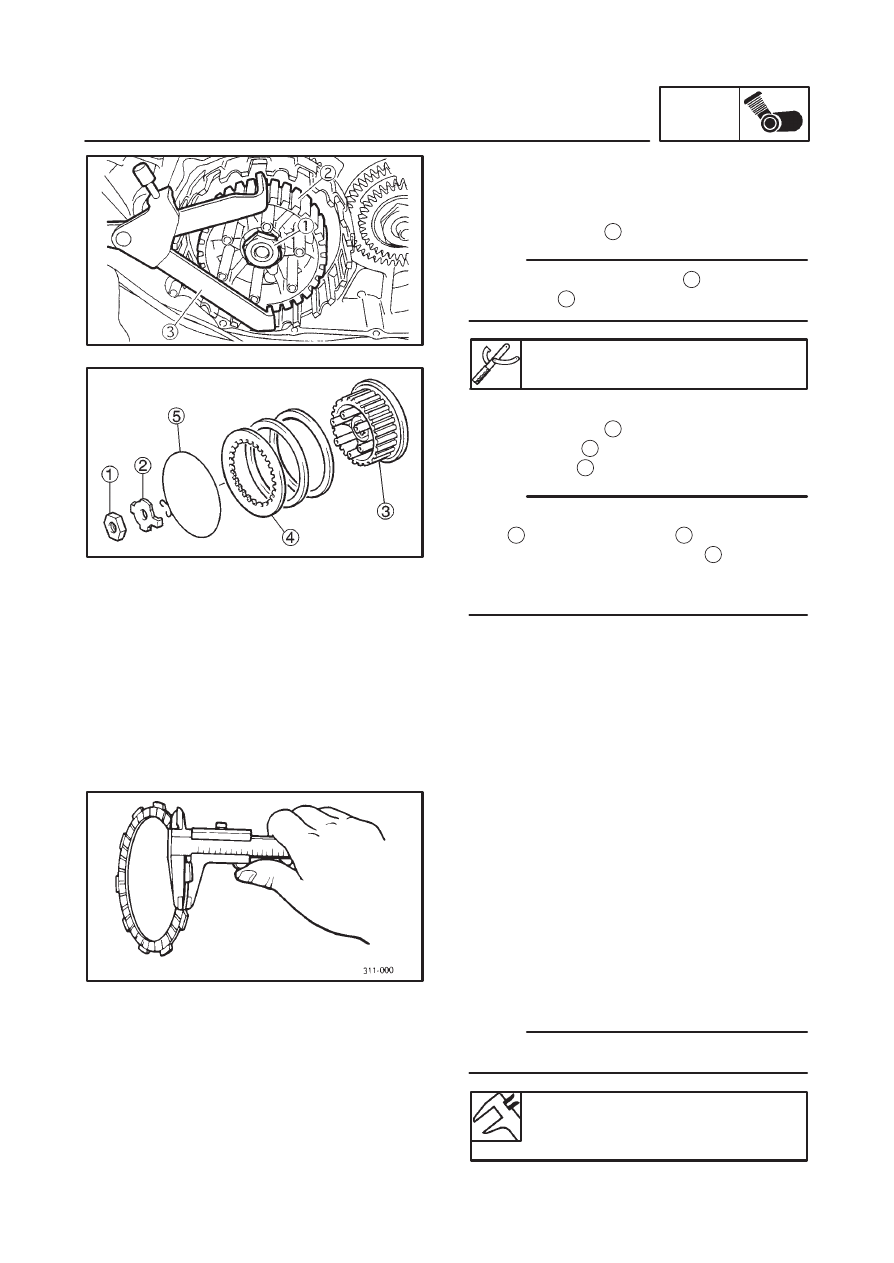

REMOVING THE CLUTCH

1. Straighten the lock washer tab.

2. Loosen:

clutch boss nut

1

While holding the clutch boss

2

with the clutch

holding tool

3

, loosen the clutch boss nut.

Clutch holding tool

90890-04086

3. Remove:

clutch boss nut

1

lock washer

2

clutch boss

3

There is a built-in damper between the clutch

boss

3

and the clutch plate

4

. It is not neces-

sary to remove the wire circlip

5

and disas-

semble the built-in damper unless there is seri-

ous clutch chattering.

EAS00281

CHECKING THE FRICTION PLATES

The following procedure applies to all of the fric-

tion plates.

1. Check:

friction plate

Damage / wear

Replace the friction plates

as a set.

2. Measure:

friction plate thickness

Out of specification

Replace the friction

plates as a set.

Measure the friction plate at four places.

Friction plate thickness

2.9

3.1 mm

<Limit>: 2.8 mm