Yamaha YFM45FAR, YFM450FAR. Service Manual - part 18

7 - 29

DRIV

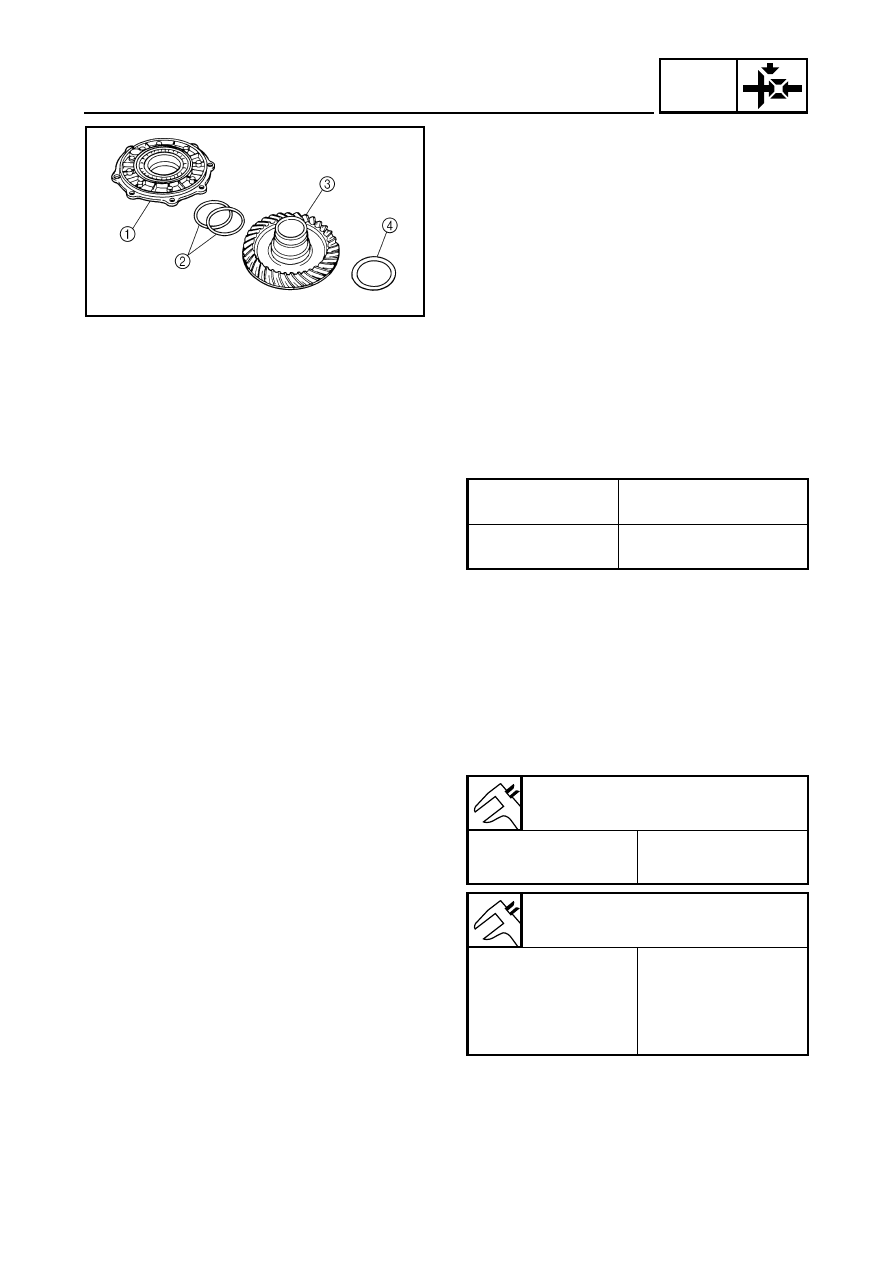

REAR AXLE/FINAL DRIVE GEAR AND DRIVE SHAFT

Final gear lash adjustment

1.Remove:

●

Bearing housing

1

●

Ring gear shim(s)

2

●

Ring gear

3

●

Thrust washer

4

2.Adjust:

●

Gear lash

*****************************************************

Adjustment steps:

●

Select a suitable shim(s) and thrust

washer(s) using the following chart.

●

If increased by more than 0.2 mm (0.008 in):

Reduce the thrust washer thickness by

0.2 mm (0.008 in) for every 0.2 mm

(0.008 in) of ring gear shim increase.

●

If reduced by more than 0.2 mm (0.008 in):

Increase the thrust washer thickness by

0.2 mm (0.008 in) for every 0.2 mm

(0.008 in) that the ring gear shim is

decreased.

*****************************************************

Too little gear lash

Reduce shim

thickness.

Too large gear lash

Increase shim

thickness.

Ring gear shim

Thickness (mm)

0.25

0.30

0.35

0.40

0.45

0.50

Thrust washer

Thickness (mm)

1.0

1.1

1.2

1.3

1.35

1.4

1.45

1.5

1.55

1.6

1.7

1.8

1.9

2.0

2.1