Yamaha YFM45FAR, YFM450FAR. Service Manual - part 17

7 - 13

DRIV

FRONT CONSTANT VELOCITY JOINTS AND

DIFFERENTIAL GEAR

3.Install:

●

Universal joint yoke

●

O-ring

●

Washer

●

Nut

Use a universal joint holder

1

.

Universal joint holder:

P/N. YM-04062, 90890-04062

LT

T

R

.

.

62 Nm (6.2 m • kg, 45 ft • lb)

4.Check:

●

Differential gear operation

Unsmooth operation

→

Replace the

differential gear assembly.

Insert the double off-set joint into the

differential gear, and turn the gear back and

forth.

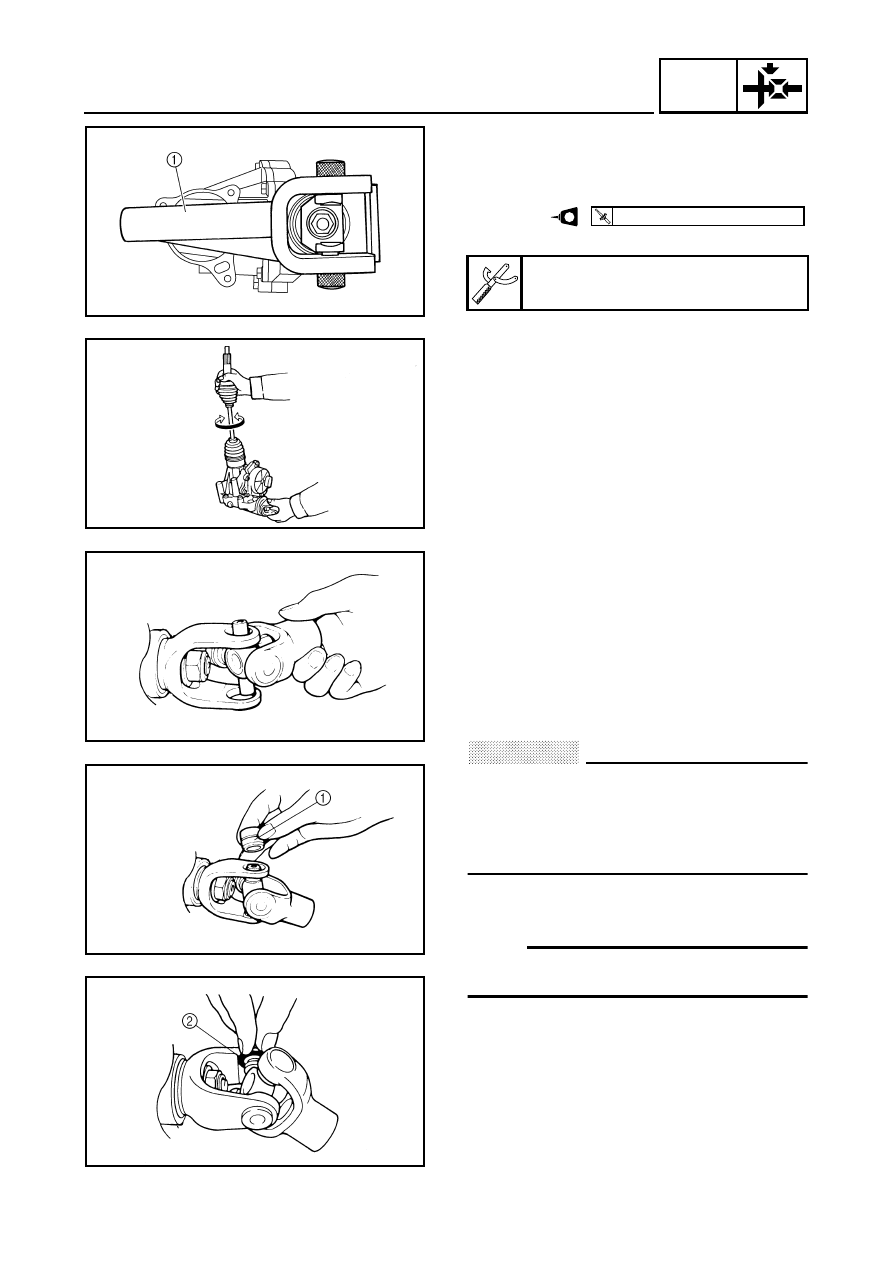

INSTALLING THE UNIVERSAL JOINT

1.Install:

●

Universal joint

*****************************************************

Installation steps:

●

Install the opposite yoke into the U-joint.

●

Apply wheel bearing grease to the bearings.

●

Install the bearing

1

onto the yoke.

CAUTION:

Check each bearing. The needles can

easily fall out of their races. Slide the yoke

back and forth on the bearings; the yoke

will not go all the way onto a bearing if a

needle is out of place.

●

Press each bearing into the U-joint using a

suitable socket.

NOTE:

The bearing must be inserted far enough into

the U-joint so that the circlip can be installed.

●

Install the circlips

2

into the groove of each

bearing.

*****************************************************