Suzuki GSX-R1000. Service Manual - part 26

1J-6 Charging System:

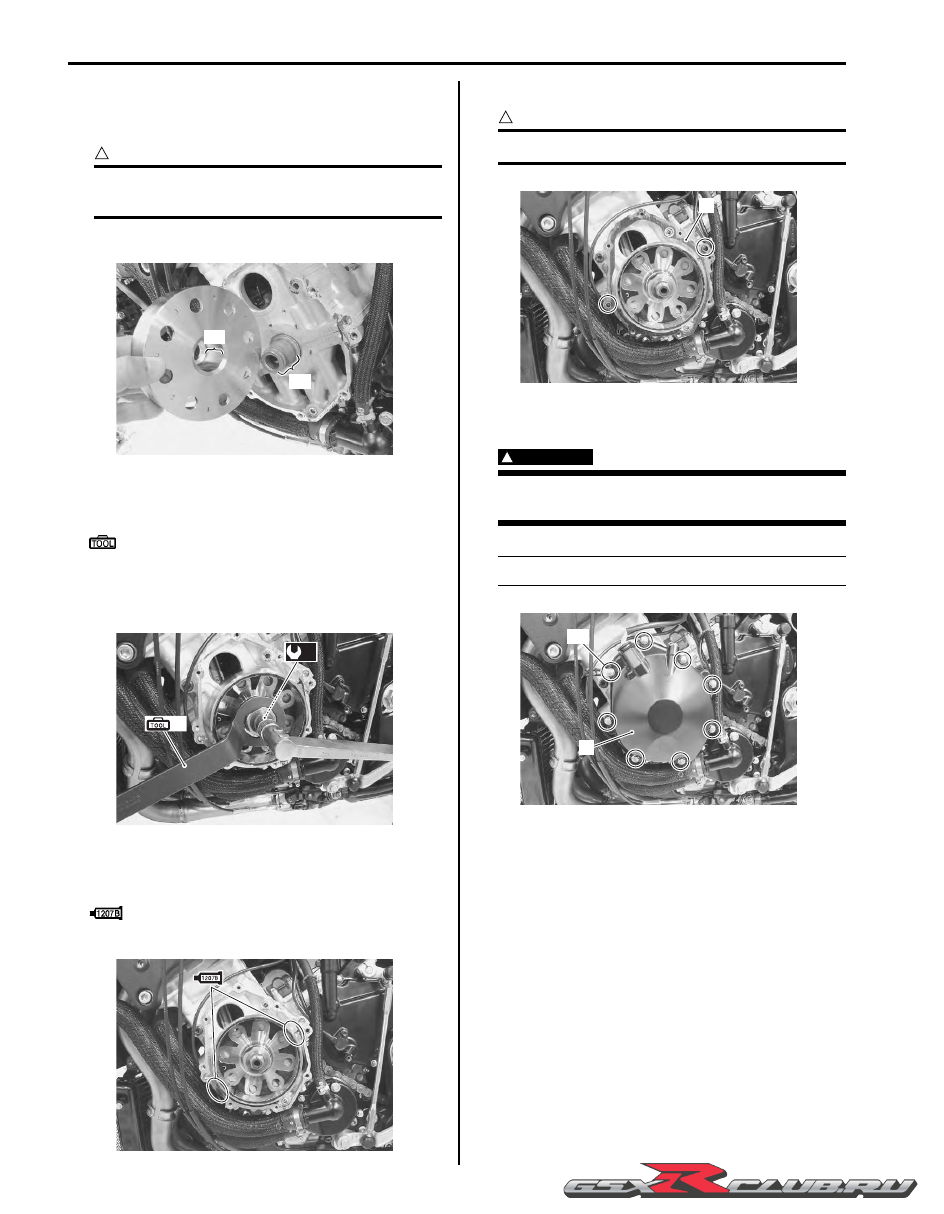

• Degrease the tapered portion “A” of generator rotor

and also the crankshaft “B” with nonflammable

cleaning solvent.

CAUTION

!

Dry these parts naturally. Do not wipe them

with a cloth or use compressed air to dry.

• Install the generator rotor onto crankshaft.

• Hold the generator rotor with the special tool and

tighten its bolt to the specified torque.

Special tool

(A): 09930–44530 (Rotor holder)

Tightening torque

Generator rotor bolt (c): 145 N·m (14.5 kgf-m,

105.0 lbf-ft)

• Apply a bond lightly to the mating surfaces at the

parting line between the upper and lower crankcases

as shown.

: Sealant 99000–31140 (SUZUKI BOND

No.1207B or equivalent)

• Install the dowel pins and new gasket (2).

CAUTION

!

Use new gasket to prevent oil leakage.

• Install the generator cover (3) and tighten the

generator cover bolts.

WARNING

!

Be careful not to pinch the finger between the

generator cover and crankcase.

NOTE

Fit the clamp to the generator cover bolt “C”.

• Route the generator lead wire. Refer to “Wiring

Harness Routing Diagram” in Section 9A (Page 9A-7).

“A”

“B”

I947H11A0023-01

(A)

(c)

I947H11A0012-02

I947H11A0013-01

2

I947H11A0014-01

3

“C”

I947H11A0015-01