Suzuki GSX-R1000. Service Manual - part 24

1H-1 Ignition System:

Engine

Ignition System

General Description

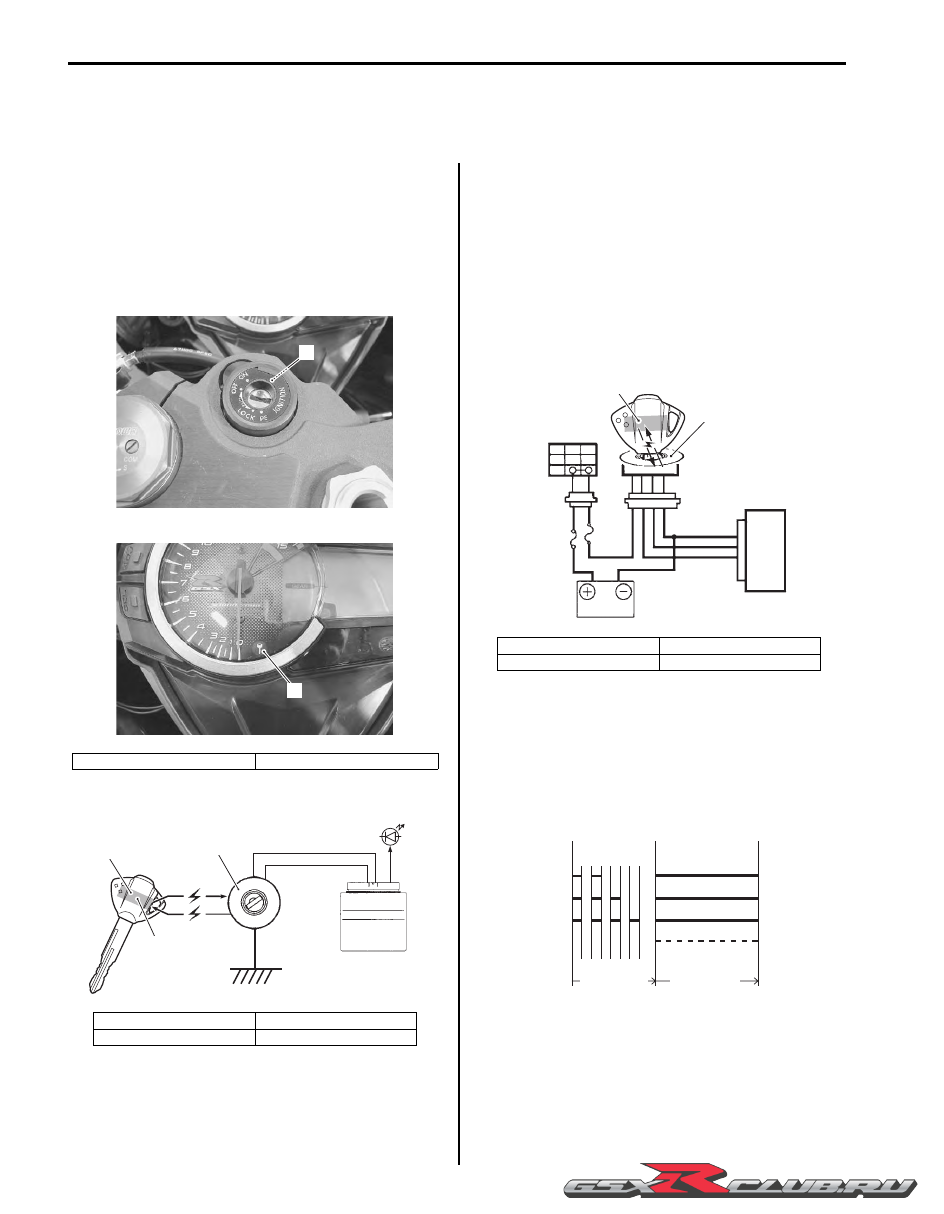

Immobilizer Description (For E-02, 19, 24, 51)

B947H11801001

The immobilizer, an anti-theft system, is installed as a

standard equipment.

The immobilizer verifies that the key ID agrees with ECM

ID by means of radio communication through the

immobilizer antenna. When the ID agreement is verified,

the system makes the engine ready to start.

Operation

When the ignition switch is turned ON with the engine

stop switch in ON, the immobi-antenna and ECM are

powered ON.

The ECM transmits a signal to the transponder through

the immobi-antenna in order to make comparison

between the key ID and ECM ID.

With the signal received, the transponder transmits the

key ID signal to ECM so that ECM can make comparison

with its own ID, and if it matches, the engine is made

ready to start.

Also, when the ignition switch is turned ON, the indicator

light flashes as many as the number of IDs registered in

ECM. Thereafter, if the IDs are in agreement, the

indicator light turns on for two seconds to notify of

completion in successful communication.

If the indicator light (LED) flashes fast, it notifies of

communication error or disagreement of ID.

1. Immobilizer antenna

2. Indicator light

1. Immobilizer antenna

3. Transponder

2. Indicator light

4. ID

1

I947H1180001-01

2

I947H1180002-01

ECM

1

2

3

4

I815H1180002-02

1. Immobilizer antenna

3. Ignition switch

2. Transponder

4. ECM

OFF

ON

R

O

1

2

3

4

I815H1180003-01

Flashing

Lighting

2 registered

3 registered

4 registered

Normal

Normal

Normal

Abnormal

Fast flashing

Approx. 1.6 sec.

Approx. 2.0 sec.

I705H1180006-01