CFMoto ATV CF500/CF500-A. Service Manual - part 12

15. Engine Removal, Inspection & Installation

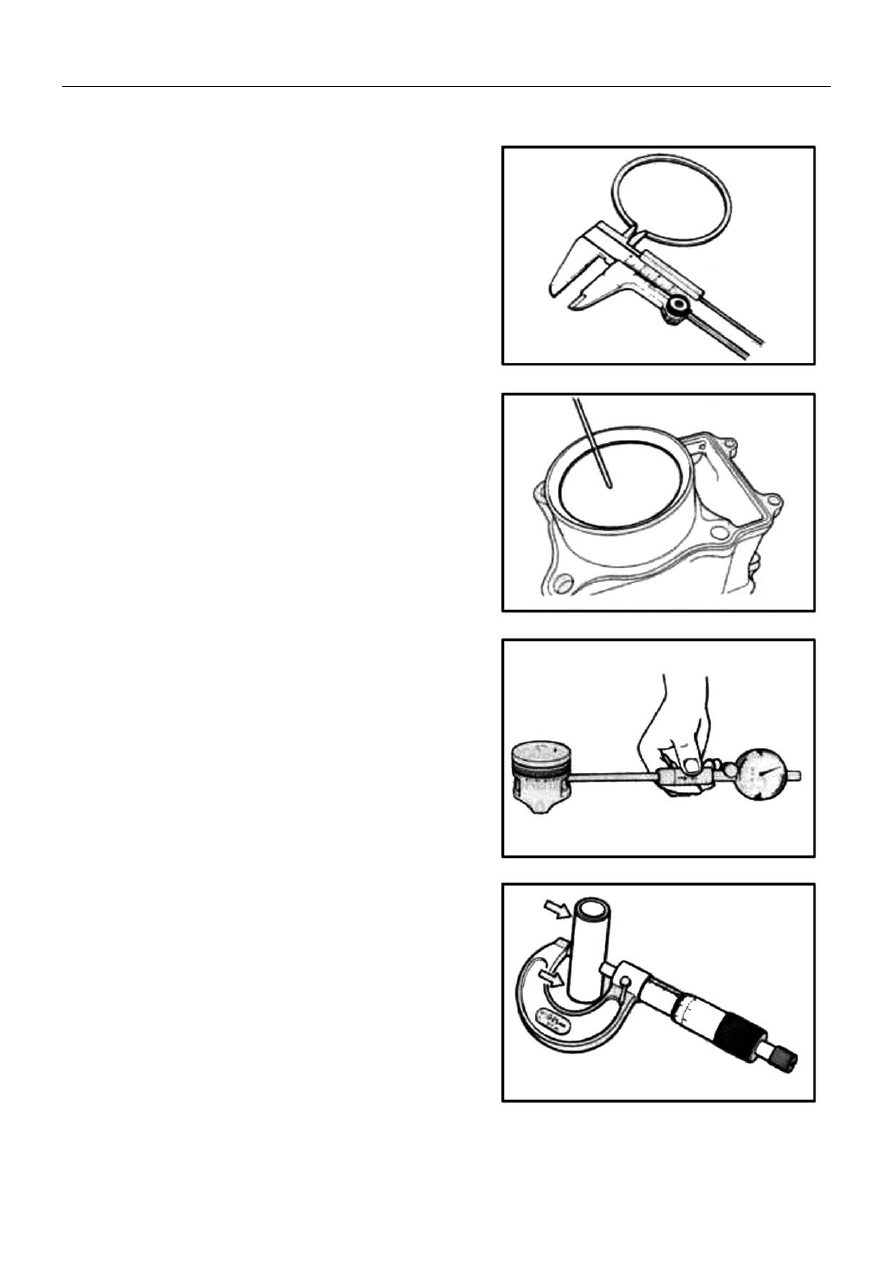

Piston Ring Free End Gap and End Gap

z

Before installing piston rings, use vernier caliper to

measure the free end gap of each ring, and then fit

ring into the cylinder.

z

Use thickness gauge to measure each ring end gap,

if any ring has an excess end gap, replace the

piston ring.

Piston ring free end gap limit:

Top ring: 8.9mm

2

nd

ring: 9.5mm

Piston ring end gap limit:

Top Ring: 0.60mm

2

nd

ring: 0.60mm

Tool: Vernier caliper

Thickness gauge

Piston Pin and Pin Bore

z

Use a bore gauge to measure the inner diameter of

piston pin bore.

z

Use micrometer to measure outer diameter of piston

pin.

z

If out of limit, replace both piston and piston pin.

Piston pin bore limit: 23.030mm

z

Use micrometer to measure piston pin outer

diameter at three points

Piston pin outer diameter limit: 22.980mm

Tools: Bore gauge (18-35mm)

Micrometer (0-25mm)

15-26