CFMoto ATV CF500/CF500-A. Service Manual - part 10

14. Checks & Adjustment

Inspection:

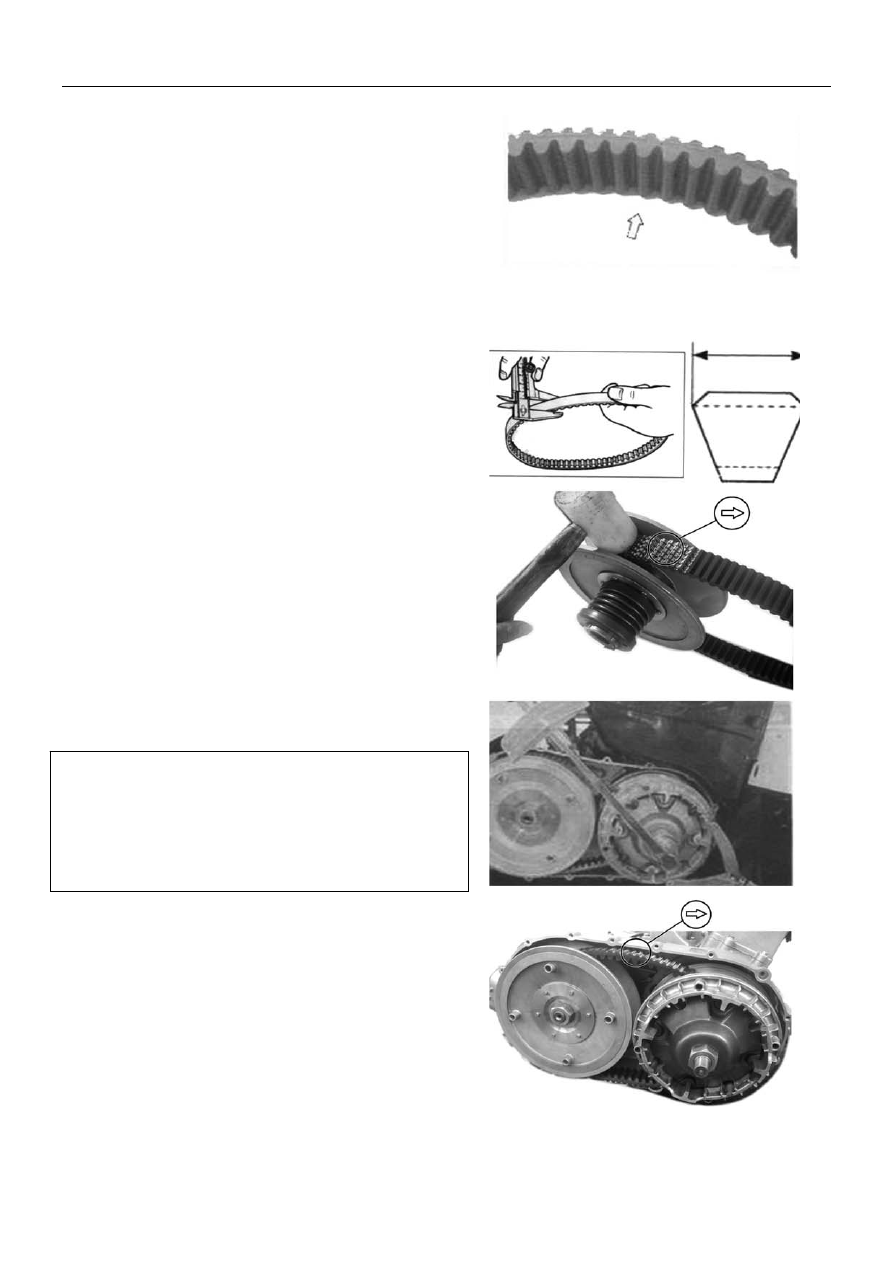

Inspect drive belt for wear and damage. If any cracks or

damages are found, replace drive belt with a new one.

Inspect drive belt for width, if width is out of

service limit,

replace drive belt with a new one.

Service Limit: 33.5mm

Tool: Vernier Caliper

Installation

Reverse the removal procedure for installation. Pay

attention to the following:

Insert drive belt, as low as possible, between secondary

sliding sheave and primary fixed sheave.

Hold secondary sheave with a special tool and tighten

the nut to the specified torque.

Nut, Secondary Sheave: 115 N.m

Install primary sheave and nut. Hold the primary sheave

with a special tool and tighten the nut to the specified

torque.

Nut, Primary Sheave:115N.m

Turn primary sheave, until the drive belt is properly

seated and both the primary and secondary sheaves

rotate together smoothly and without slipping.

Caution:

z

Fit the drive belt with the arrow on the drive belt

points toward normal turning direction.

z

The drive belt contact surface of the driven face

should be thoroughly cleaned.

Install CVT cover

14-7