CFMoto ATV Terralander CF800-2. Service Manual - part 7

17 TROUBLESHOOTING

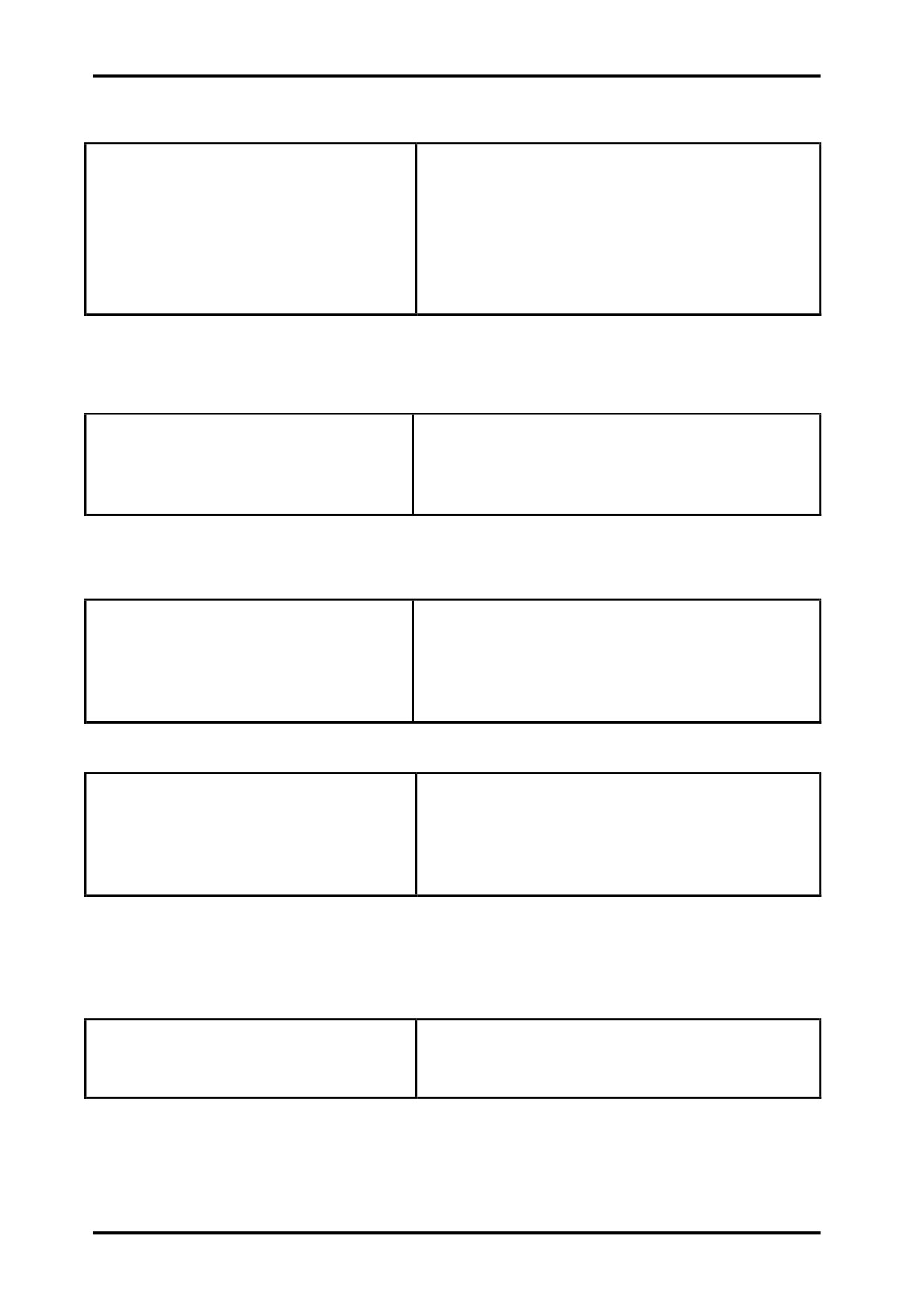

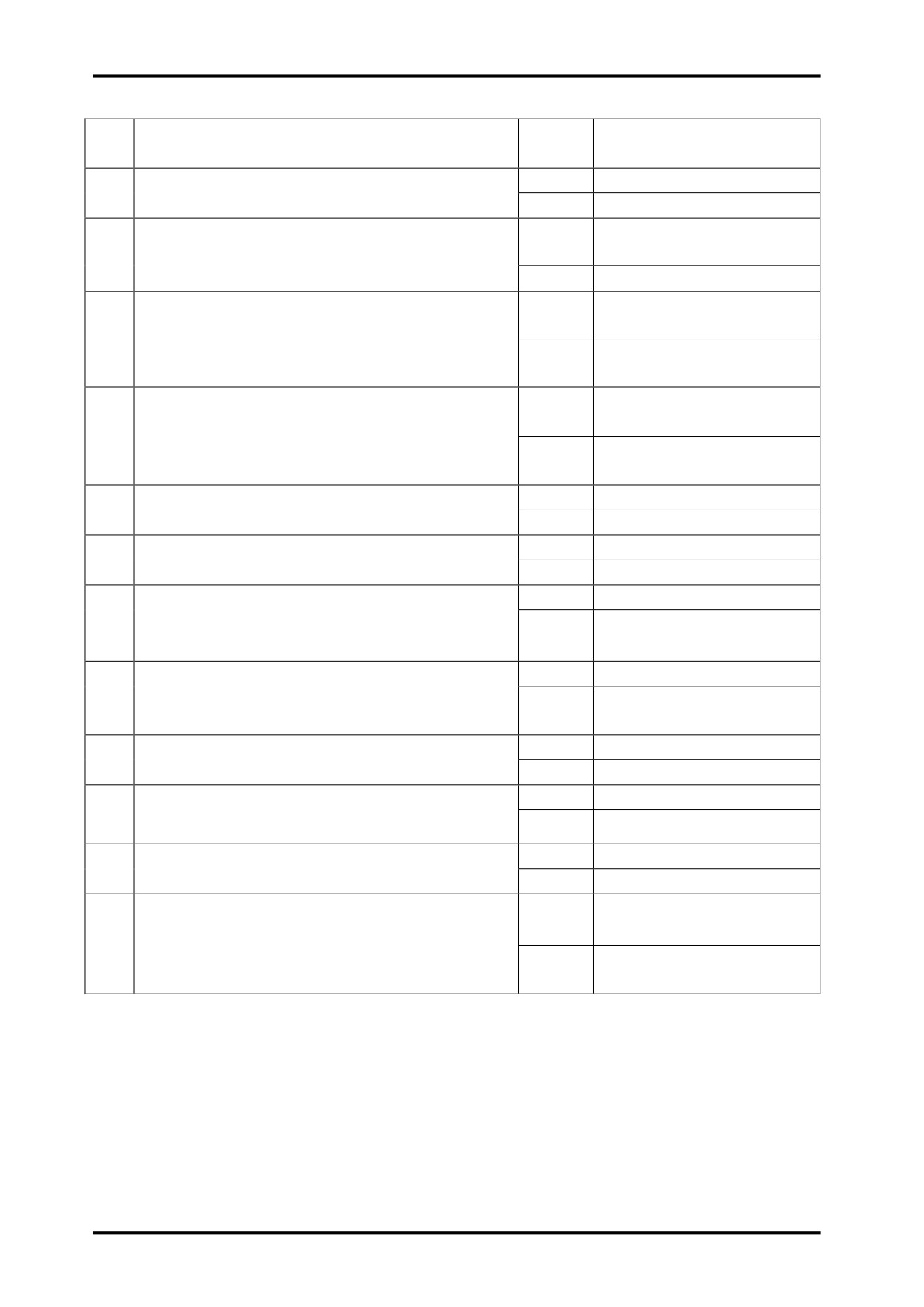

Trouble code P0107:Intake air temp. sensor low voltage or open circuit

Possible causes:

Repair procedures:

1)The sensor short circuit to ground

1)Measure resistance between ECU and ground

Trouble code P0108:Intake air temp. sensor high voltage

Possible causes:

Repair procedures:

1)The sensor short circuit to ground

1)Measure ECU pin voltage

Trouble code P0112: Intake air temp. sensor low voltage

Possible causes:

Repair procedures:

1)The sensor connected with ECU pin short circuit

1)Measure resistance between ECU pin and ground

to ground

Trouble code P0113:Intake air temp. sensor high voltage or open circuit

Possible causes:

Repair procedures:

1)The sensor connected with ECU pin short circuit

1)Measure sensor voltage connected with ECU pin if it’s ok.

to power

Trouble code P0117:Water temp. sensor low voltage

Possible causes:

Repair procedures:

1)The sensor connected with ECU pin short circuit

1) Measure resistance between ECU pin and ground.

to ground

Trouble code P0118:Water temp. sensor high voltage or open circuit

Possible causes:

Repair procedures:

1)The sensor connected with ECU pin short circuit

1) Measure voltage of ECU pin if it’s ok.

to other circuit.

17-9

17 TROUBLESHOOTING

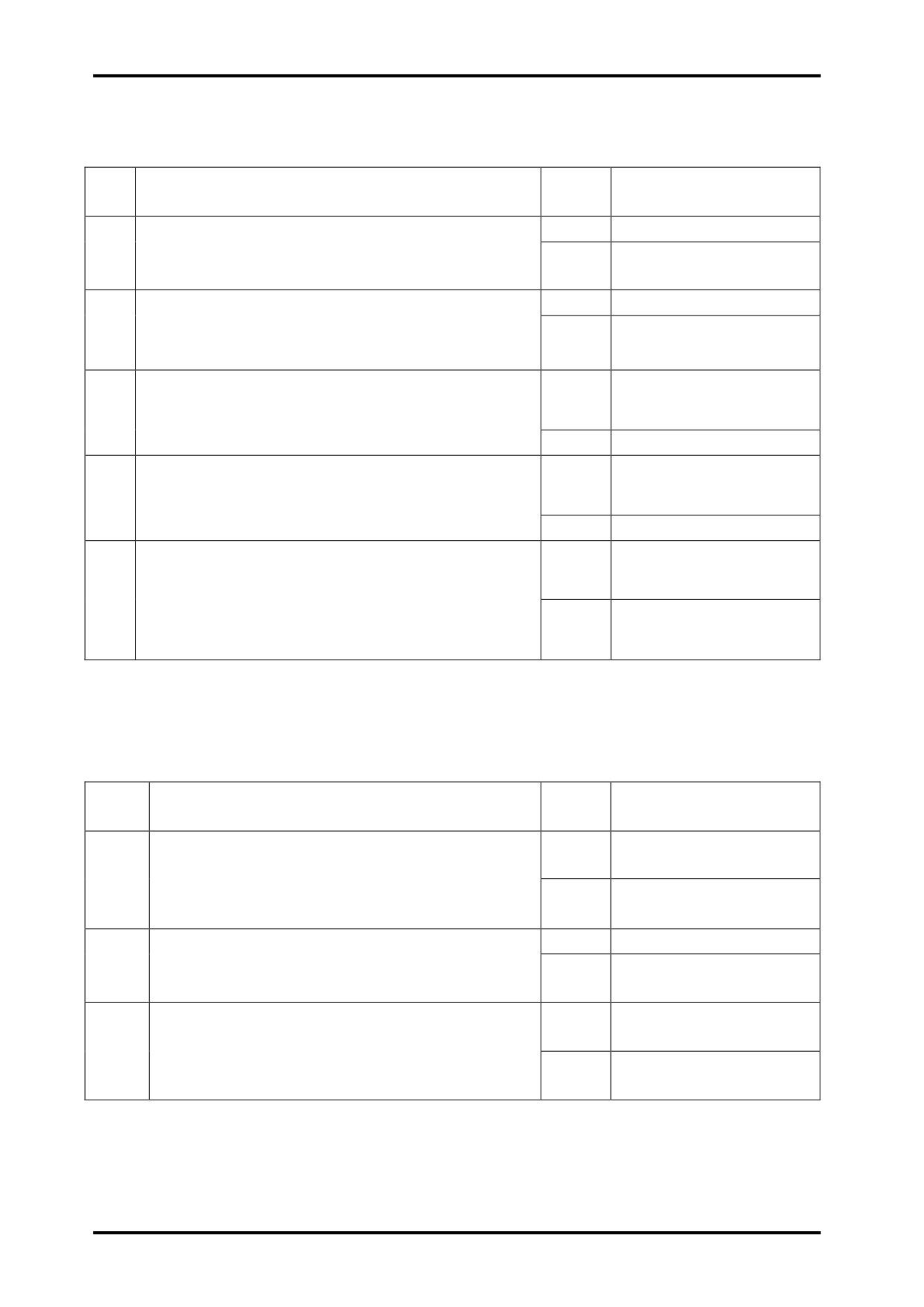

Trouble code P0122:TPS low voltage or open circuit

Possible causes:

Repair procedures:

1)ECU pin short circuit to ground

1)Measure resistance between ECU pin and ground

Trouble code P0123:TPS high voltage

Possible causes:

Repair procedures:

1)Short circuit between ECU pin and other circuit

1)Measure voltage connected with ECU pin if it’s ok.

Trouble code P0201/ P0202: 1/2 cylinder injector coil defective

Possible causes:

Repair procedures:

1) Injector coil if it’s open circuit.

1) Measure injector resistance

2) Improper connection between injector pin and

2) Check continuity of all wirings

ECU pin

3)Measure resistance between ECU pin and ground

3) Improper connection between injector pin and

4)Measure voltage connected with ECU pin.

relay

4)All drive circuit connected with ECU short to ground

5)Short circuit between ECU pin and other circuit.

Trouble code P0336: Pick-up (Crankshaft phase sensor) signal incorrect

Possible causes:

Repair procedures:

1) Wiring continuity short circuit or open circuit from

1) Check wiring continuity if it’s ok.

time to time

2) Check flywheel rotor gear quantity.

2) Installation of crankshaft signal wheel improperly

3) RPM sensor installation improperly

Trouble code P0337:Pick-up (crankshaft phase sensor) no signal

After engine is started, ECU will monitor pick-up signal and other signals at the same time.

It will judge if pick-up signal is missing or not by signal reasonability.

Possible causes:

Repair procedures:

1)Open circuit between RPM sensor and ECU

1) Measure resistance between pick-up and ECU

2)Short circuit between pick-up and ECU

2) Measure resistance of pick-up

3)Open circuit of pick-up coil.

3) Measure peak voltage of pick-up.

17-10

17 TROUBLESHOOTING

Trouble code P0230:Fuel pump relay coil low voltage or open circuit

Trouble code P0232:Fuel pump relay coil high voltage

Possible causes:

Repair procedures:

1) Open circuit/short to ground/short to power

1)Measure resistance or voltage between ECU and fuel pump

between control circuit of fuel pump relay

relay.

connected with ECU and fuel pump replay

2)Measure resistance between fuel pump relay and main

2)Open circuit between fuel pump relay and main

relay.

relay.

3)Measure resistance between two pins of fuel pump relay.

3)Open circuit between relay coils.

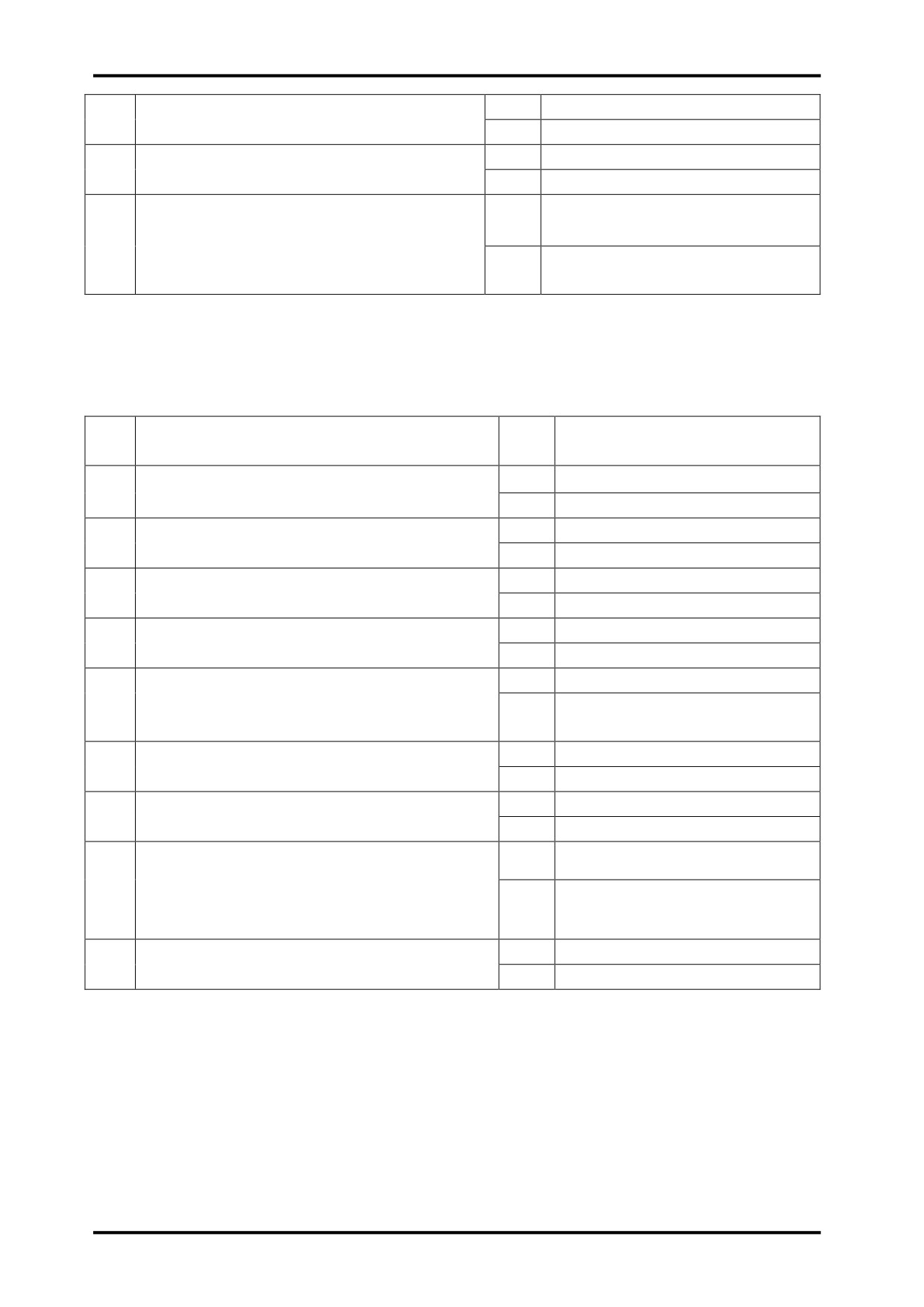

Trouble code P0505:Out of idle speed when at idle condition

Engine idle speed is controlled by ECU close-loop. In case ECU gives idle instruction, but engine

idle speed still is higher than targeted idle speed set by ECU, then it’s trouble.

Possible causes:

Repair procedures:

1) Check adjust screw of throttle, throttle cable

1)Switch off ignition more than 3 seconds and restart engine.

and throttle working condition if it’s ok.

2)Too dirty inside throttle body.

Trouble code P0562:Battery low voltage

Trouble code P0563:Battery high voltage

Possible causes:

Repair procedures:

1)Flywheel already broken and cannot generate

1) Check flywheel power generation ( By measuring flywheel

power or battery power leakage

voltage)

2)Open circuit of flywheel stator coil.

2) Measure regulator voltage

3)Regulator already damaged

Trouble code P0650:MIL light drive circuit defective

Possible causes:

Repair procedures:

1) Open circuit/short to ground/short to power

1)Measure resistance or voltage between ECU and MIL light

between ECU and MIL light drive circuit.

drive circuit.

2)Open circuit between MIL and main relay

3)MIL light burnt

Trouble code P0500: Speed sensor no signal

When vehicle is running with gear and with loose throttle body, ECU will monitor engine RPM

and speed sensor. In case engine has high RPM, but speedometer shows 0 or very low, then it’s

a trouble of speed sensor.

Possible causes:

Repair procedures:

1)Short or open circuit between ECU and speed

1) Measure resistance between ECU pins and speed sensor.

sensor

2)Measure resistance between ECU pins and ground

17-11

17 TROUBLESHOOTING

Trouble code:P0850 Nuetral gear sensor defective

Engine cannot be started when at “N” gear position.

Possible causes:

Repair procedures:

1)Open circuit between N gear sensor and ground

1) Measure resistance between ECU pin and N gear sensor

Trouble code:P0445 Starter auxiliary relay high voltage

Trouble code:P0444 Starter auxiliary relay low voltage or open circuit

Possible causes:

Repair procedures:

1)Open circuit/short to ground/short to power

1)Measure resistance or voltage between ECU and auxiliary

between ECU and auxiliary relay.

relay.

2)Open circuit between auxiliary relay and power.

2)Measure resistance between auxiliary relay and power.

3)Open circuit between relay coils.

3)Measure resistance between auxiliary relay two pins.

Trouble code P1693:RPM low output voltage

Trouble code P1694:RPM high output voltage

After engine is started, ECU will monitor pick-up signal and other signals.

It will judge if pick-up signal is missing or not by signal reasonability.

Possible causes:

Repair procedures:

1) Short circuit or open circuit between wirings

1) Check wiring continuity.

from time to time.

2) Check flywheel rotor gear quantity.

2) Improper installation of crankshaft signal

3) Measure resistance between pick-up and ECU

wheel.

4) Measure resistance of pick-up

3) Improper installation of RPM sensor

5) Measure peak voltage of pick-up.

4) Open circuit between RPM sensor and ECU

5) Short circuit between pick-up and ECU

6) Open circuit between pick-up coils

Trouble code P0351/ P0352:1/2 ignition coil defective

Possible causes:

Repair procedures:

1) Ignition coil open circuit

1) Measure resistance of ignition coil

2) Improper connection between ignition coil and

2) Check wiring continuity.

ECU pins.

3)Measure resistance between ECU pin and ground

3) Improper connection between ignition coil and

4)Measure voltage between ECU pins

relay.

4)Short circuit between drive circuit connected

with ECU and ground.

5)Short circuit between ECU pin and other circuits

17-12

17 TROUBLESHOOTING

4. Trouble diagnosis by engine problems

Before trouble diagnosis by engine problems, initial checking should be done as follows.

1. Confirm if trouble light is ok;

2. Confirm there’s no trouble code record by PDA checking.

3. Confirm there’s really trouble existing complained by end-users.

Then check the following points.

(1) Check fuel hoses if any fuel leakage;

(2) Check vacuum pipes if any broken, twist or improper connection;

(3) Check intake manifold if any blocked, air leakage or damaged;

(4) Check high-tension cable if any damaged, aging;or ignition order is correct.

(5) Check wiring close to ground if it’s clean and firm;

(6) Check connector of all sensors and actuator if any loose or improper connection.

Important note: In case there’re some problems as above-mentioned, then removal work should be done

firstly, then go to next diagnosis.

Diagnosis helps:

1. Confirm engine without any trouble record.;

2. Confirm there’s really trouble existing;

3. During checking, do not neglect vehicle periodic maintenance, cylinder pressure, valve timing, fuel supply

and so on;

4. Replace ECU to test.

In case trouble disappears, then it’s a problem of ECU. If trouble still exists, then assemble original ECU and

check other points.

Frequent troubles list:

z

When starting engine, engine cannot rotate or rotate slowly.

z

When starting engine, starter motor can rotate but cannot start engine.

z

Difficult to start warm or hot engine

z

Difficult to start cold engine

z

RPM is ok, but difficult to start engine.

z

Starting is ok, but idle speed is unstable at any time.

z

Starting is ok, but idle speed is unstable during engine warm-up period.

z

Starting is ok, but idle speed is unstable after engine warm-up.

z

Starting is ok, idle speed is unstable or engine stop when switch on some lights or other electric

components.

z

Starting is ok, but too high idle speed.

z

RPM cannot go up or engine stop when acceleration.

z

Slow acceleration.

z

Insufficient power and bad performance when acceleration.

17-13

17 TROUBLESHOOTING

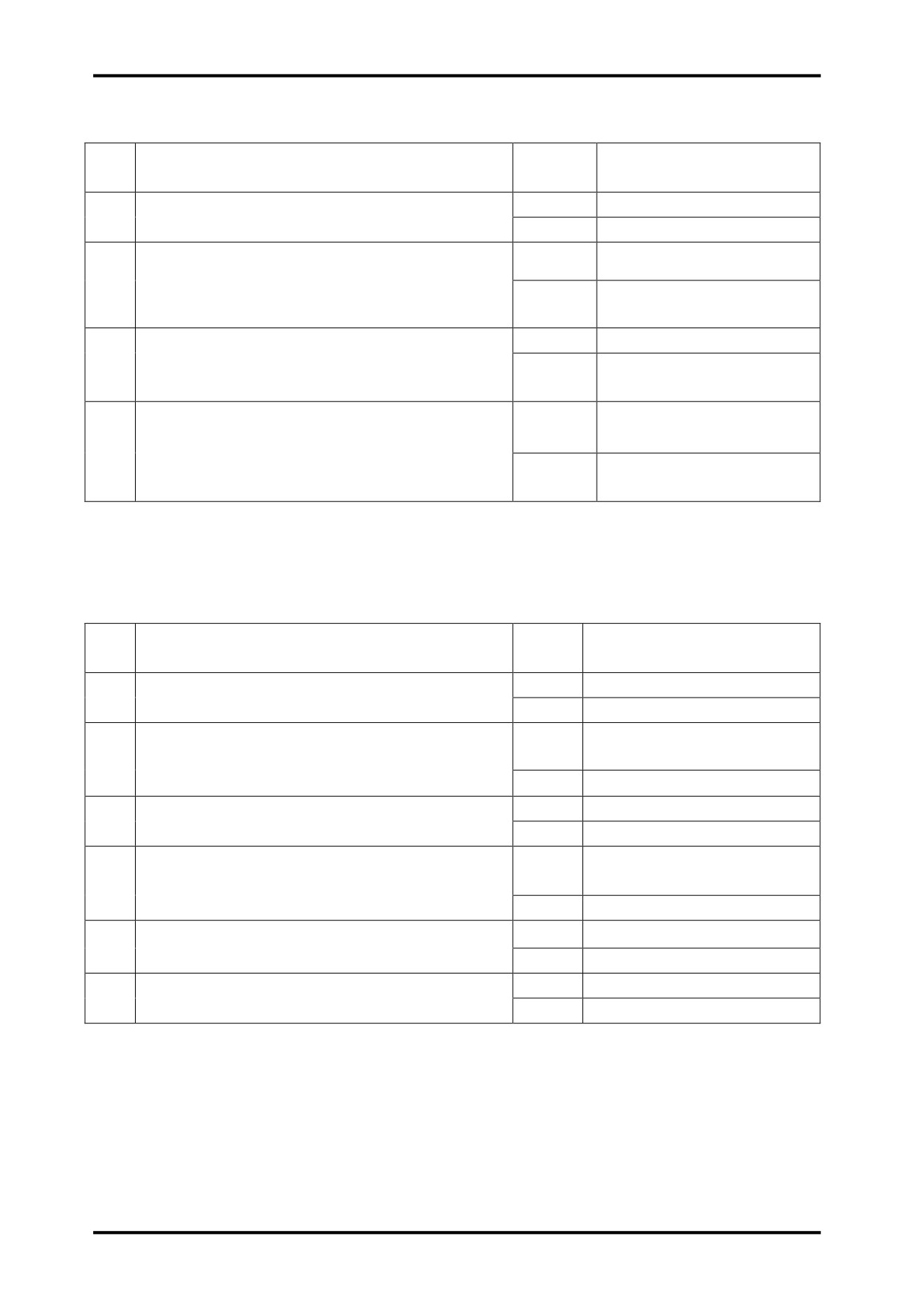

(1)When starting, engine cannot rotate or rotate slowly.

Possible causes:1. battery;2. starter motor;3. wiring or ignition switch;4. engine mechanical part.

General operation procedures:

Item

operation procedures

Result

Then

No.

Use multimeter to measure voltage between positive and

Yes

Next step

1

negative terminals of battery, normal value should be 8-12V

No

Replace battery

when starting engine.

Yes

Next step

Keep ignition switch on starting position, then use multimeter to

2

measure voltage of positive terminal of starter motor. Normal

No

Repair or replace wiring

value should be more than 8V.

Remove starter motor and check if any open circuit or blocked

Yes

Repair or replace starter motor

3

by bad lubrication

No

Next step

If trouble only exists in winter, then resistance of starter motor

Yes

Change good engine oil

4

is too big by unsuitable engine oil.

No

Next step

Yes

Check resistance inside engine

5

Check if mechanical resistance is too big inside engine

No

Repeat above procedures

(2)When starting, starter motor can rotate but engine cannot be started.

Possible causes:1. No fuel inside fuel tank;2. Fuel pump;3. Pick-up;4. Ignition coil;

5. Engine mechanical part.

General operation procedures:

Item

Operation procedures

Result

Then

No.

Switch on ignition switch(repeat several times if necessary)

Yes

Next step

or start engine and use fuel pressure meter to measure fuel

1

pressure of fuel pump. Correct value should be around

No

Check fuel supply system

330Kpa (3.30Bar)

Yes

Next step

Use PDA to see RPM data, and start engine to check if any

2

RPM signal output.

No

Check RPM sensor wiring

Disconnect high-tension cable and connect spark plug, keep

Yes

Next step

3

spark plug 5mm away from engine body, then start engine to

check if any white/blue spark occurs.

No

Check ignition system

17-14

17 TROUBLESHOOTING

Yes

Remove engine mechanical trouble

4

Check cylinder pressure if it’s enough or not

No

Next step

Connect PDA and switch on ignition to check ECU-J2-15 pin

Yes

Use PDA to diagnose

5

and J2-18 pin if it is powered normally; Check ECU-J1-9 pin

and J2-2 pin if it is connected to ground normally.

No

Check and repair wiring circuit

(3)Difficult to start hot or warm-up engine

Possible causes:1. Fuel with water;2. Fuel pump;3. Water temp. sensor;4. Ignition coil.

General operation procedures:

Item

Operation procedures

Result

Then

No.

Yes

Next step

Connect fuel pressure meter and start engine to measure

1

fuel pressure if it’s around 330Kpa (3.30Bar)

Check and repair fuel supply

No

system

Disconnect high-tension cable and connect spark plug, keep

Yes

Next step

2

spark plug 5mm away from engine body, then start engine to

see if there’s blue and white spark.

No

Check and repair ignition system

Check and repair wiring or

Disconnect connector of water temp. sensor and start

Yes

replace sensor

engine, check if engine can be started successfully. (or use a

3

300Ω resistant to connect water temp. sensor connector and

No

Next step

check if engine can be started successfully.

No

Next step

Yes

Change fuel

4

Check fuel quality and if it’s caused only after filling fuel.

No

Next step

Connect PDA and switch on ignition to check ECU-J2-15 pin

Yes

Use PDA to diagnose

5

and J2-18 pin if it is powered normally; Check ECU-J1-9 pin

and J2-2 pin if it is connected to ground normally.

No

Check & repair wiring

(4)Difficult to start cold engine

Possible causes:1. Fuel with water;2. Fuel pump;3. Water temp. sensor;4. Injector;5. Ignition coil;

6.Throttle body and air by-pass valve;7. Engine mechanical part

General operation procedures:

17-15

17 TROUBLESHOOTING

Item

Operation procedures

Result

Then

no.

Yes

Next step

Use fuel pressure meter and start engine to measure

1

if fuel pressure is around 330Kpa (3.30Bar)

No

Check and repair fuel supply system

Disconnect high-tension cable and connect spark

Yes

Next step

2

plug, keep it 5mm away from engine body, then start

engine to check if there’s blue and white spark.

No

Check and repair ignition system

Disconnect connector of water temp. sensor, start

Yes

Check and repair wiring or sensor

engine and check if it can be started successfully. (or

3

use 2500Ω resistant to connect sensor and check if

No

Next step

engine can be started successfully.

Clean throttle body and air by-pass

Open throttle very slowly to check if it can be started

Yes

4

valve

easily.

No

Next step

Remove injector and use special cleaning equipment

Yes

Replace injector

5

to check if any leakage or blocked

No

Next step

Check fuel quality and if it is caused just after filling

Yes

Change fuel

6

fuel

No

Next step

Yes

Remove engine mechanical problem

7

Check cylinder pressure if it is enough or not.

No

Next step

Connect PDA and switch on ignition to check

Yes

Use PDA to diagnose

ECU-J2-15 pin and J2-18 pin if it is powered normally;

8

Check ECU-J1-9 pin and J2-2 pin if it is connected to

No

Check and repair wiring

ground normally.

(5)RPM is ok, but difficult to start engine at any time.

Possible causes:1. Fuel with water;2. Fuel pump;3.Water temp. sensor;4. Injector;5. Ignition coil;

6.Throttle body and air by-pass valve;7. Intake manifold;8. Ignition timing;9. Spark plug;

10. Engine mechanical part

General operation procedures:

Item

Operation procedures

Result

Then

No.

Check air filter if any blocked, or intake manifold if any

Yes

Check and repair intake manifold

1

blocked or leakage

No

Next step

17-16

17 TROUBLESHOOTING

Yes

Next step

Use fuel pressure meter and start engine to check if fuel

2

pressure is around 330Kpa (3.30Bar)

Check and repair fuel supply

No

system

Disconnect spark plug cap and connect spark plug, keep it

Yes

Next step

3

5mm away from engine body, then start engine to check if

there’s blue and white spark.

No

Check and repair ignition system

Yes

Next step

4

Check spark plug if it is under technical specifications.

No

Adjust or replace

Check and repair wiring or replace

Disconnect water temp. sensor connector and start engine to

Yes

5

sensor

check if it can be started successfully.

No

Next step

Open throttle very slowly to check if engine can be started

Yes

Clean throttle body

6

easily.

No

Next step

Remove injector and use special cleaning equipment to check

Yes

Replace injector

7

if any leakage or blocked.

No

Next step

Yes

Change fuel

8

Check fuel quality and if it is caused just after filling fuel.

No

Next step

Yes

Remove engine mechanical part

9

Check cylinder pressure if it is enough.

No

Next step

Yes

Next step

10

Check ignition timing if it is ok.

No

Check and repair ignition timing

Connect PDA and switch on ignition to check ECU-J2-15 pin

Yes

Use PDA to diagnose

11

and J2-18 pin if it is powered normally; Check ECU-J1-9 pin

and J2-2 pin if it is connected to ground normally.

No

Check and repair wiring

(6)Starting is ok, but idle speed is unstable at any time

Possible causes:1. Fuel with water;2. Injector;3. Spark plug;4.Throttle body;5.Intake manifold;

6. Air by-pass valve;7.Ignition timing;8.Spark plug;9. Engine mechanical part

General operation procedures:

Item

Operation procedures

Result

Then

No

Check and repair intake manifold

Check air filter if any blocked, or intake manifold if any air

Yes

1

system

leakage.

No

Next step

17-17

17 TROUBLESHOOTING

Yes

Clean or replace

2

Check if air by-pass valve is blocked

No

Next step

Yes

Next step

3

Check spark plug if it’s under technical specifications.

No

Adjust or replace

Check throttle body and by-pass air pipe if any carbon

Yes

Clean

4

deposit.

No

Next step

Remove injector and use special cleaning equipment to

Yes

Replace

5

check if any leakage, blocked or incorrect fuel flow and so

No

Next step

on.

Yes

Change fuel

6

Check fuel quality and judge it’s caused just after filling fuel.

No

Next step

Yes

Remove mechanical problem

7

Check cylinder pressure if it’s not enough.

No

Next step

Yes

Next step

Check mechanical ignition timing if it’s under technical

8

specifications.

No

Check and repair ignition timing

Connect PDA and switch on ignition to check ECU-J2-15 pin

Yes

Use PDA to diagnose

9

and J2-18 pin if it is powered normally; Check ECU-J1-9 pin

and J1-2 pin if it is connected to ground normally.

No

Check and repair wiring

(7)Starting is ok, but idle speed is unstable during engine warming-up.

Possible causes:1. Fuel with water;2. Water temp. sensor;3. Spark plug;4. Throttle body and by-pass air

pipe;5.Intake manifold;6.Air by-pass valve;7. Engine mechanical part

General operation procedures:

Item

Operation procedures

Resul

Then

No.

t

Check air filter if any blocked or intake manifold any

Yes

Check air filter and intake manifold

1

leakage

No

Next step

Yes

Next step

2

Check spark plug if it’s under technical specifications.

No

Adjust or replace

Remove air by-pass valve and check throttle body, air

Yes

Clean it

3

by-pass valve and idle by-pass pipe if any carbon deposit.

No

Next step

Remove water temp. sensor and start engine to check if

Yes

Check wiring or replace sensor

4

engine can keep stable idle during warming-up.

No

Next step

Remove injector and use special cleaning equipment to

Yes

Replace

5

check if any leakage, blocked or incorrect fuel flow and so

No

Next step

on.

17-18

19 TROUBLESHOOTING

Check fuel quality and if it’s caused just after filling

Yes

Change fuel

6

fuel.

No

Next step

Yes

Remove engine mechanical problem

7

Check cylinder pressure if it’s out of range.

No

Next step

Connect PDA and switch on ignition to check

Yes

Use PDA to diagnose

ECU-J2-15 pin and J2-18 pin if it is powered normally;

8

Check ECU-J1-9 pin and J2-2 pin if it is connected to

No

Check and repair wiring

ground normally.

(8)Starting is ok, but idle speed is unstable after engine warming up.

Possible causes:1. Fuel with water;2. Water temp. sensor;3. Spark plug;4. Throttle body and idle by-pass

pipe;5. Intake manifold;6. Air by-pass valve;7. Engine mechanical part

General operation procedures:

Item

Operation procedures

Re-

Then

No.

sult

Check air filter if any blocked, and intake manifold if any

Yes

Check&repair air filter &intake manifold

1

leakage.

No

Next step

Yes

Next step

2

Check spark plug if it’s under technical specifications.

No

Adjust or replace

Remove air by-pass valve, check throttle body, air

Yes

Clean it

3

by-pass valve and it pipe if any carbon deposit.

No

Next step

Disconnect connector of water temp. sensor and start

Yes

Check & repair wiring or replace sensor

4

engine to see if any unstable idle during warming up

No

Next step

Remove injector and use special cleaning equipment to

Yes

Replace it

5

check if any leakage, blocked or incorrect fuel flow and

No

Next step

so on.

Yes

Change fuel

6

Check fuel quality if it’s caused just after filling fuel.

No

Next step

Yes

Remove mechanical problem

7

Check cylinder pressure if it’s out of range.

No

Next step

Connect PDA and switch on ignition to check

Yes

Use PDA to diagnose

ECU-J2-15 pin and J2-18 pin if it is powered normally;

8

Check ECU-J1-9 pin and J2-2 pin if it is connected to

No

Check & repair wiring

ground normally.

Turn off ignition, and switch on ignition to restart engine

Yes

9

after 3 seconds.

No

Check & repair wiring

(9)Starting is ok, but idle speed is unstable or killed off when lights (or other electrical components) switched

on.

17-19

17 TROUBLESHOOTING

Possible causes: 1. Air by-pass valve;2. Injector

General operation procedures:

Item

Operation procedures

Results

Then

No.

Remove air by-pass valve, check throttle body, air by-pass

Yes

Clean it

1

valve and it pipe if any carbon deposit.

No

Next step

Check engine output power if it is too big when switching

Yes

Operate step 4

2

on electric components. And use PDA to check advanced

No

Next step

ignition angle, fuel spray width and air intake flow.

Remove injector and use special cleaning equipment to

Yes

Replace it

3

check if any leakage, blocked or incorrect fuel flow and so

No

Next step

on.

Connect PDA and switch on ignition to check ECU-J2-15

Yes

Use PDA to diagnose

pin and J2-18 pin if it is powered normally; Check

4

ECU-J1-9 pin and J2-2 pin if it is connected to ground

No

Check&repair wiring

normally.

(10)Starting is ok, but idle speed is too high.

Possible causes:1.Throttle body and idle pipe; 2.Injector seat;3. Air by-pass valve;4. Water temp. sensor;

5. Ignition timing

General operation procedures:

Item

Operation procedures

Result

Then

No.

Yes

Adjust

1

Check throttle cable if it is blocked or too tight.

No

Next step

Yes

Check&repair air intake system

2

Check air intake system and injector seat if any leakage

No

Next step

Remove air by-pass valve, check throttle body, air by-pass

Yes

Clean it

3

valve and its pipe if any carbon deposit.

No

Next step

Check&repair wiring or replace

Disconnect connector of water temp. sensor and start

Yes

4

sensors

engine to check if idle speed is too high.

No

Next step

Yes

Next step

5

Check ignition timing if it is under technical specifications.

No

Check & repair ignition timing

Turn off ignition, switch on ignition after 3 seconds and

Yes

6

restart engine.

No

Check & repair wiring

17-20

17 TROUBLESHOOTING

Connect PDA and switch on ignition to check ECU-J2-15 pin

Yes

Use PDA to diagnose

6

and J2-18 pin if it is powered normally; Check ECU-J1-9 pin

and J2-2 pin if it is connected to ground normally.

No

Check &repair wiring

(11)RPM cannot go up or engine stop when acceleration

Possible causes:1. Fuel with water;;2.Air intake sensor and TPS;3. Spark plug;4.Throttle body and its idle

pipe;5.Intake manifold;6.Air by-pass valve;7. Injector;8.Ignition timing;9. Exhaust pipe

General diagnosis procedures:

Item

Operation procedures

Result

Then

No.

Check air filter if any blocked, and intake manifold if any

Yes

Check&repair air intake system

1

leakage.

No

Next step

Use fuel pressure meter and start engine to measure fuel

Yes

Next step

2

pump pressure. Normal value should be around 330Kpa

(3.30Bar)

No

Check&repair fuel supply system

Yes

Next step

3

Check spark plug if it’s under technical specifications.

No

Adjust or replace

Remove air by-pass valve, check throttle body, air by-pass

Yes

Clean it

4

valve and it pipe if any carbon deposit.

No

Next step

Yes

Next step

5

Check air intake temp. sensor, TPS and its wiring if it is ok.

Check&repair wiring or replace

No

sensor

Remove injector and use special cleaning equipment to

Yes

Replace it

6

check if any leakage, blocked or incorrect fuel flow and so

No

Next step

on.

Yes

Change fuel

7

Check fuel quality and if it’s caused just after filling fuel.

No

Next step

Yes

Next step

Check ignition order and ignition timing if it is under

8

technical specifications.

No

Check&repair ignition timing

Yes

Next step

9

Check exhaust pipe if any leakage or blocked.

No

Repair & replace exhaust pipe

Connect PDA and switch on ignition to check ECU-J2-15

Yes

Use PDA to diagnose

pin and J2-18 pin if it is powered normally; Check

10

ECU-J1-9 pin and J2-2 pin if it is connected to ground

No

Check&repair wiring

normally.

17-21

17 TROUBLESHOOTING

(12)Slow acceleration

Possible causes:1.Fuel with water;2. Air intake pressure sensor and TPS;3. Spark plug;4. Throttle body

and its idle pipe;5. Intake manifold;6. Air by-pass valve;7. Injector;8. Ignition timing;9. Exhaust pipe

General operation procedures:

Item

Operation procedures

Result

Then

No.

Check air filter if any blocked, and intake manifold if

Yes

Check&replace air intake system

1

any leakage.

No

Next step

Use fuel pressure meter and start engine to

Yes

Next step

2

measure fuel pump pressure. Normal value should

be around 330Kpa (3.30Bar)

No

Check&repair fuel supply system

Check spark plug if it’s under technical

Yes

Next step

3

specifications.

No

Adjust or replace

Remove air by-pass valve, check throttle body, air

Yes

Clean it

4

by-pass valve and it pipe if any carbon deposit.。

No

Next step

Yes

Next step

Check air intake temp. sensor, TPS and its wiring if it

5

is ok.

No

Check&repair wiring or replace sensor

Remove injector and use special cleaning

Yes

Replace it

6

equipment to check if any leakage, blocked or

No

Next step

incorrect fuel flow and so on.

Check fuel quality and if it’s caused just after filling

Yes

Change fuel

7

fuel.

No

Next step

Yes

Next step

Check ignition order and ignition timing if it is under

8

technical specifications.

No

Check&repair ignition timing

Yes

Next step

9

Check exhaust pipe if any leakage or blocked.

No

Repair or replace exhaust pipe

Connect PDA and switch on ignition to check

Yes

Use PDA to diagnose

ECU-J2-15 pin and J2-18 pin if it is powered

10

normally; Check ECU-J1-9 pin and J2-2 pin if it is

No

Check&repair wiring

connected to ground normally.

(13)Power not enough when acceleration and bad performance

Possible causes:1.Fuel with water;2. Air intake pressure sensor and TPS;3. Spark plug;4. Ignition coil;

5. Throttle body and its idle pipe;6.Intake manifold;7.Air by-pass valve;8. Injector;9. Ignition timing;10.

Exhaust pipe

17-22

17 TROUBLESHOOTING

General operation procedures:

Item

Operation procedures

Result

Then

No.

Check if any clutch slippery, or tire pressure too low, or

Yes

Repair

1

brake too tight, or tire size incorrect and so on.

No

Next step

Check air filter if any blocked, and intake manifold if any

Yes

Check&repair air intake system

2

leakage.

No

Next step

Use fuel pressure meter and start engine to measure fuel

Yes

Next step

3

pump pressure. Normal value should be around 330Kpa

(3.30Bar)

No

Check&repair fuel supply system

Yes

Next step

Disconnect high-tension cable, and connect spark plug,

4

keep it 5mm away from engine body to check if spark is ok.

No

Check&repair ignition system

Yes

Next step

5

Check spark plug if it’s under technical specifications.

No

Adjust or replace

Remove air by-pass valve, check throttle body, air by-pass

Yes

Clean it

6

valve and it pipe if any carbon deposit.。

No

Next step

Yes

Next step

7

Check air intake temp. sensor, TPS and its wiring if it is ok.

Check&repair wiring or replace

No

sensor

Remove injector and use special cleaning equipment to

Yes

Replace it

8

check if any leakage, blocked or incorrect fuel flow and so

No

Next step

on.

Yes

Change fuel

9

Check fuel quality and if it’s caused just after filling fuel.

No

Next step

Yes

Next step

Check ignition order and ignition timing if it is under

10

technical specifications.

No

Check&repair ignition timing

Yes

Next step

11

Check exhaust pipe if any leakage or blocked.

No

Repair or replace exhaust pipe

Connect PDA and switch on ignition to check ECU-J2-15

Yes

Use PDA to diagnose

12

pin and J2-18 pin if it is powered normally; Check ECU-J1-9

pin and J2-2 pin if it is connected to ground normally.

No

Check&repair wiring

17-23