CFMoto ATV CF800-2 4x4. Service Manual - part 7

Engine oil check

7.

If the engine oil is at or below the lower limit mark

,

add sufficient oil of the recommended type to

raise

it

to

the

correct level.

8. Insert the dipstick into the oil filler hole, and then tighten it.

9. Install plastic cover

①。

To change engine oil

1.

Start the engine, warm it up for 2~3 minutes, and then stop the engine.

2.

Place an oil pan under the engine to collect the used oil,

and then remove the engine oil dipstick.

3.

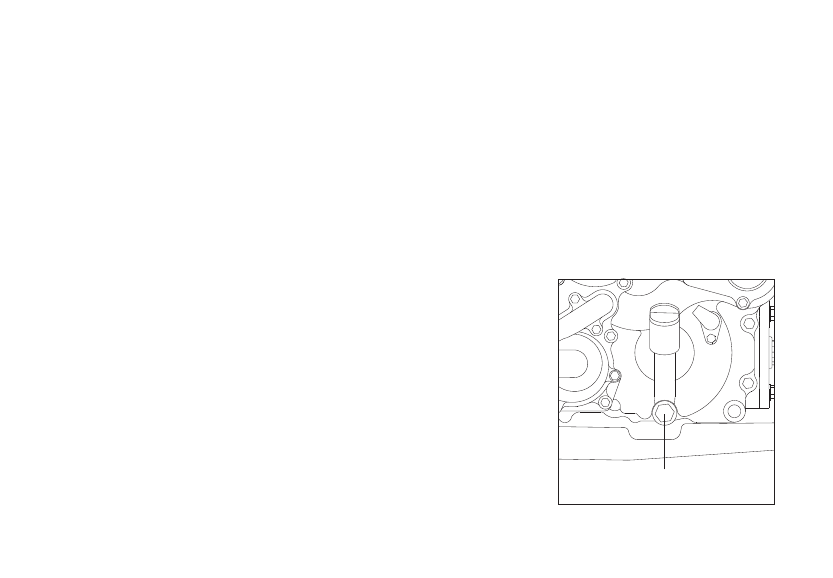

①

Remove the engine oil drain bolt

to drain the oil from the

crankcase.

-99-

①

Maintenance & Lubrication