CFMoto motorcycle CF650NK. Service Manual - part 33

16-14 ELECTRICAL SYSTEM

Battery

Charging Condition Inspection

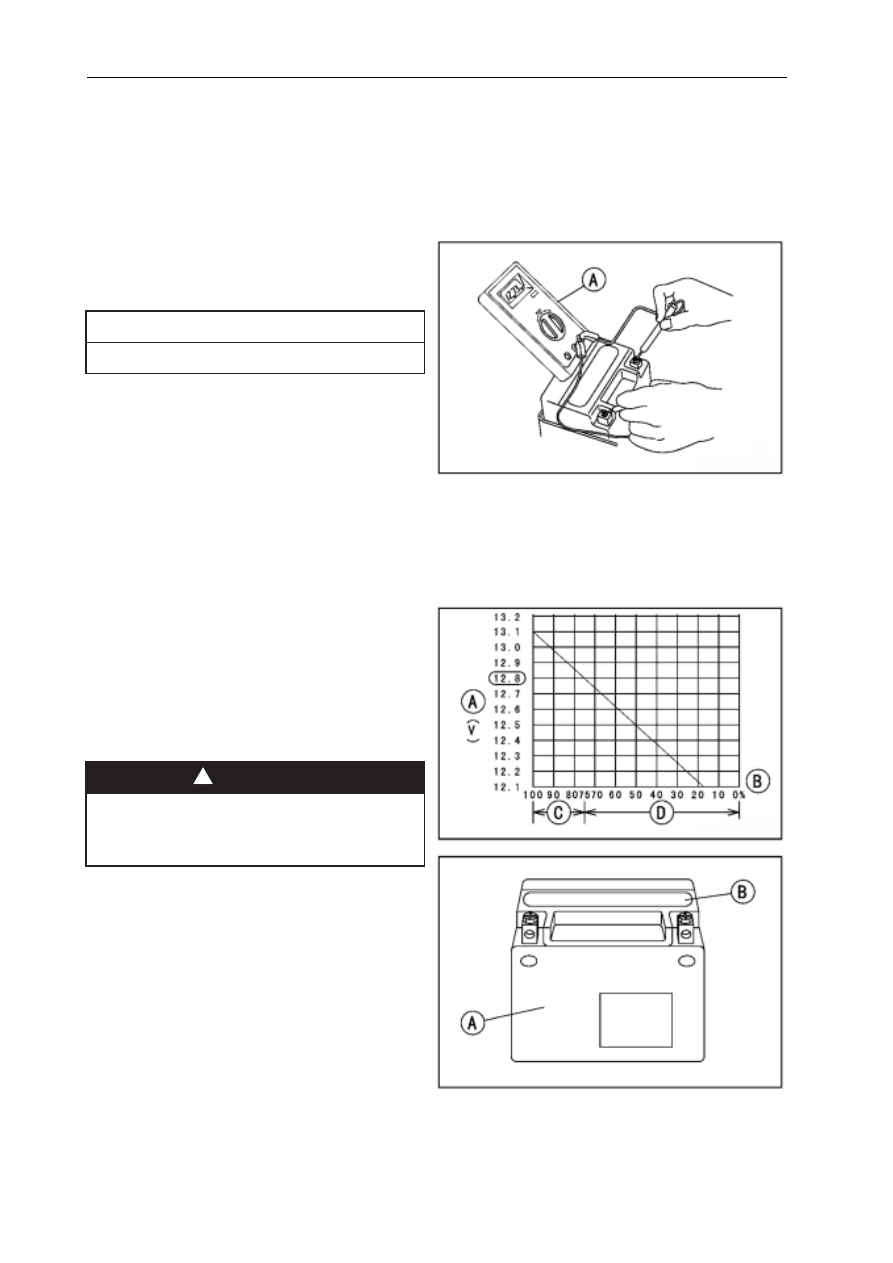

Battery charging condition can be checked by mea-

suring battery terminal voltage with a digital voltmeter

[A].

Remove:

Seat (see Seat Removal in the Frame chapter)

Battery Cable Cap (see Battery Removal)

Disconnect the battery terminals.

Be sure to disconnect the negative (-) cable first.

N

O

I

T

U

A

C

Measure the battery terminal voltage.

NOTE

o

Measure with a digital voltmeter which can be read

one decimal place voltage.

If the reading is 12.8 V or more, no refresh charge

is required, however, if the read is below the

specified, refresh charge is required.

Battery Terminal Voltage

Standard: 12.8 V or more

Terminal Voltage (V) [A]

Battery Charge Rate (%) [B] Good [C]

Refresh charge is required [D]

Refreshing Charge

Remove the battery [A] (see Battery Removal).

Do refresh charge by following method according to

the battery terminal voltage.

This battery is sealed type. Never remove seal-

ing cap [B] even at charging. Never add water.

Charge with current and time as stated below.

!

WARNING

NG