CFMoto motorcycle CF650NK. Service Manual - part 28

11-12 FINAL DRIVE

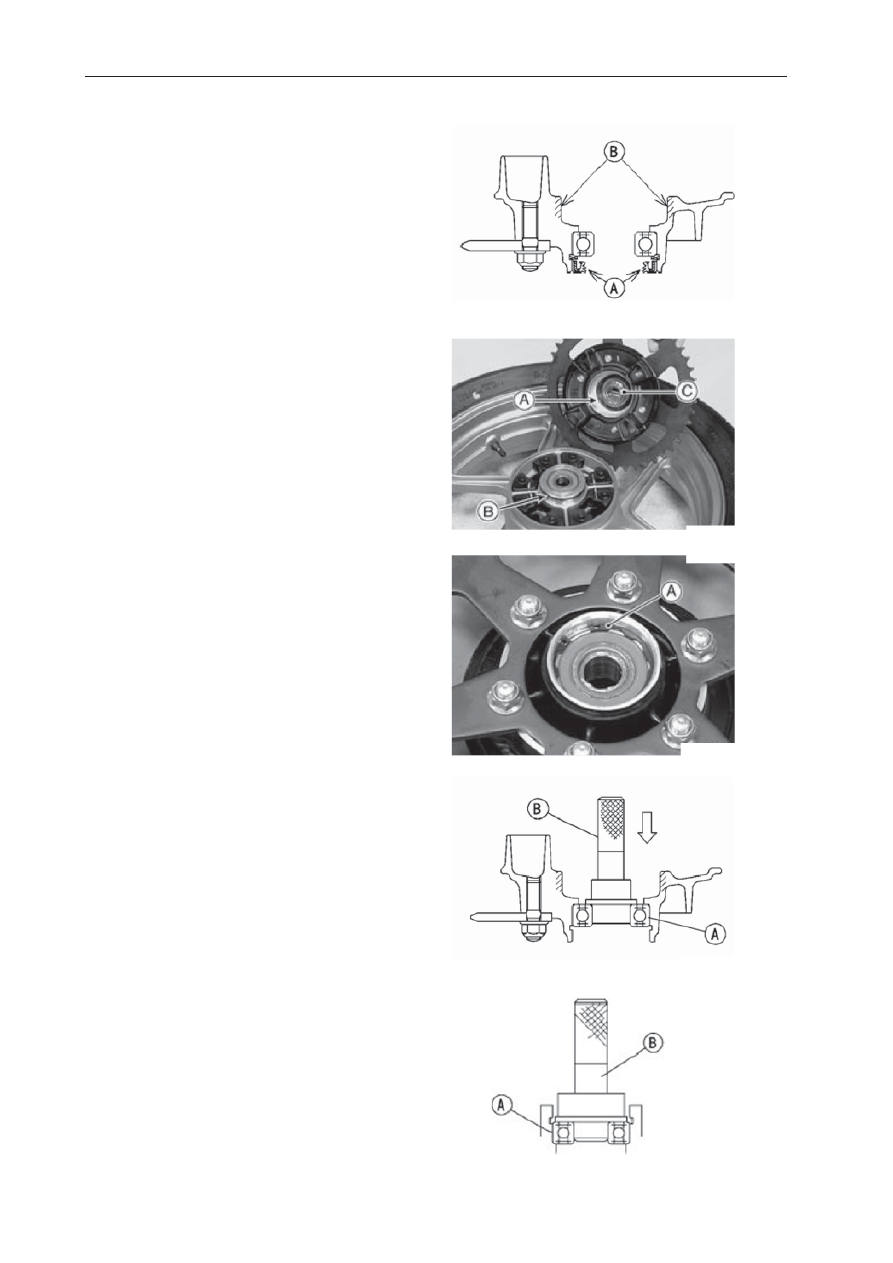

Coupling Installation

●

Apply high-temperature grease to the coupling

grease seal lips [A].

●

Apply grease to the coupling internal surface [B].

●

Grease the following.

Wheel Flange Portion [A]

O-ring [B]

●

Install the collar [C].

Coupling Bearing Removal

●

Remove:

Coupling

Grease Seal

Circlip [A]

Special Tool - Inside Circlip Pliers

●

Remove the bearing [A] by tapping from the

wheel side.

Special Tool - Bearing Driver Set [B]

Coupling Bearing Installation

●

Replace the bearing with a new one.

●

Press in the bearing [A] until it is bottomed.

Special Tool - Bearing Driver Set [B]

●

Replace the circlip with a new one.

Special Tool - Inside Circlip Pliers