CFMoto motorcycle CF650NK. Service Manual - part 27

WHEELS/TIRES 10-12

Balance Weight

Number

Weight

1

10g (0.35oz.)

2

20g (0.71oz.)

3

30g (1.06oz.)

NOTE

○

Balance weights are available from cfmoto

dealers in 10, 20, and 30 grams (0.35, 0.71, and

1.06 oz.) sizes.

An imbalance of less than 10 grams (0.35 oz.)

will not usually affect running stability.

○

Do not use four or more balance weight (more

than 90gram, 3.17 oz.). If the wheel requires an

excess balance weight, disassemble the wheel to

fi

nd the cause.

●

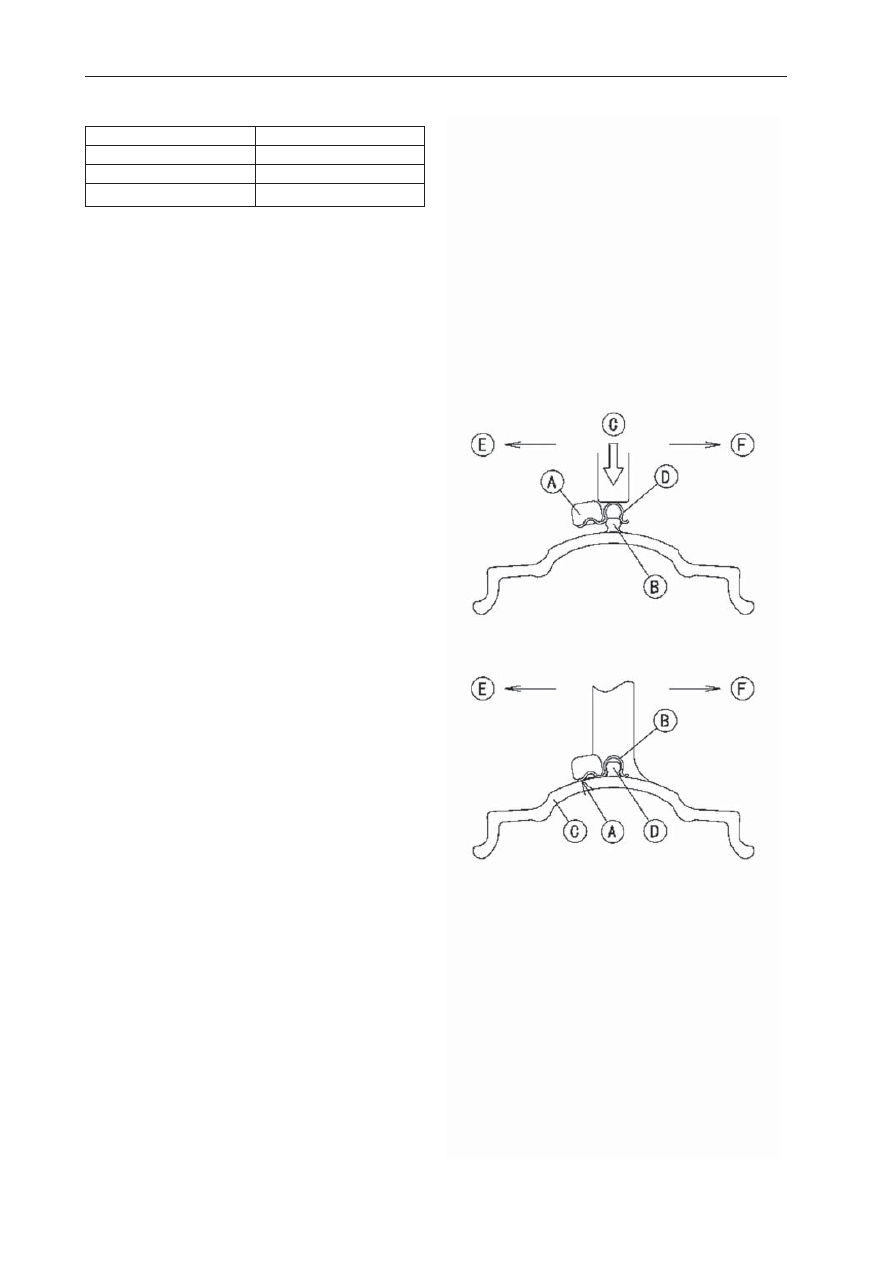

Slip the balance weight [A] onto the rib [B] by

pushing or lightly hammering [C] the clip [D].

Left Side [E] Right Side [F]

●

Be sure to install the balance weight.

○

Check that the blade [A] and clip [B] are fully

seated on the rim [C] and that the clip is hooked

over the rib [D].

Left Side [E]

Right Side [F]