CFMoto motorcycle CF650NK. Service Manual - part 21

ENGINE TOP END 5-31

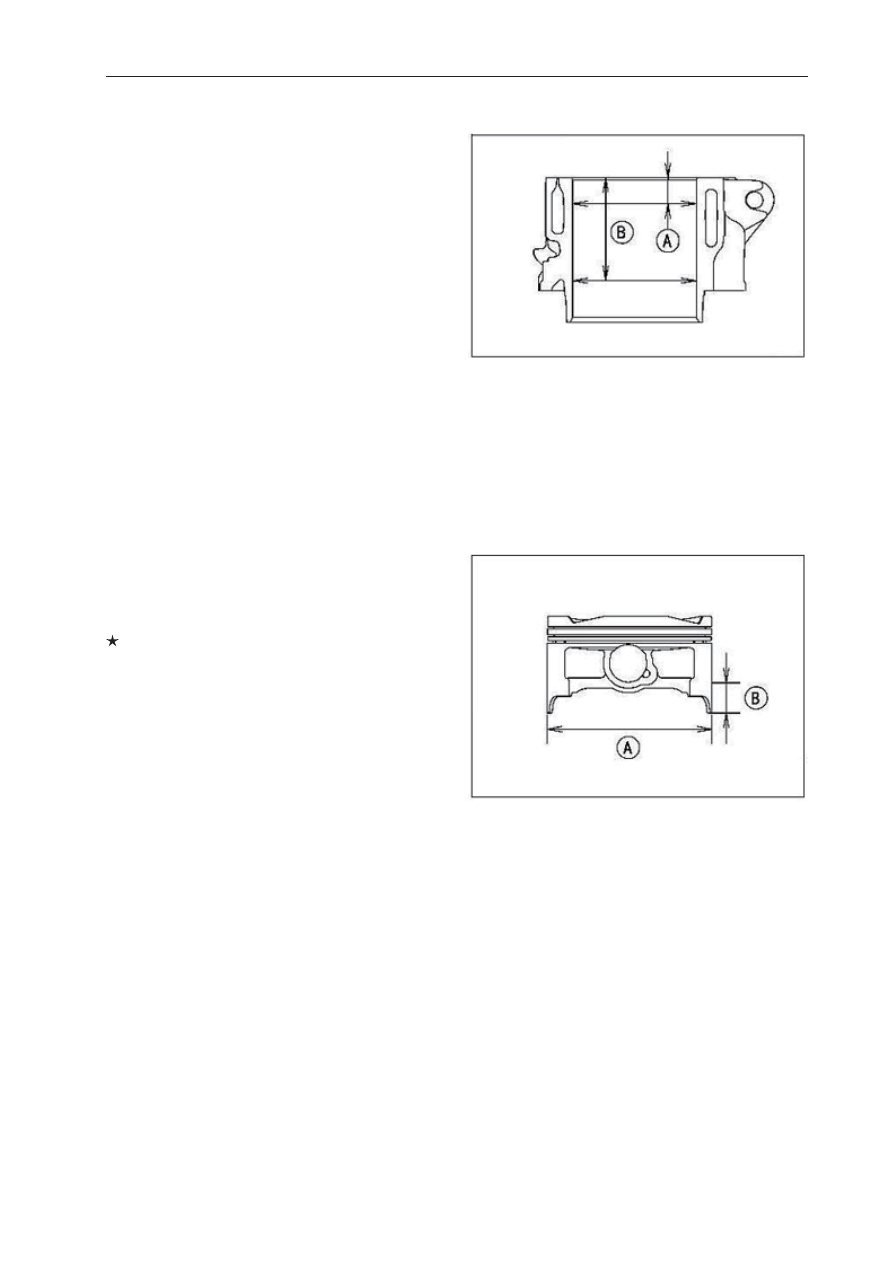

Cylinder/Pistons

Cylinder Wear

●

Since there is a difference in cylinder wear

in different directions, take a side-to-side and a

front-to-back measurement at each of the two

locations (total of four measure- ments) shown

in the

fi

gure.

10mm [A]

60mm [B]

Cylinder Inside Diameter

Standard:83.00mm~83.02mm

Service limit:83.10mm

Piston wear

●

Measure the outside diameter [A] of each piston

10mm [B] up from the bottom of the piston at a

right angle to the direction of the piston pin.

If themeasurement is under service limit, replace

the piston.

Piston diameter

Standard:82.975mm~82.995mm

Service limit : 82.90mm

Piston Ring, Piston Ring Groove Wear

●

Check for uneven groove wear by inspecting the

ring seat.