CFMoto motorcycle CF650NK. Service Manual - part 19

4-18 COOLING SYSTEM

Hose and Pipes

Hose Installation

●

Install the hoses and pipes, being careful to

follow bending direction. Avoid sharp bending,

kinking,

fl

attening or twisting.

●

Run the hoses (see Cable, Wire, and Hose

Routing section in the Appendix chapter).

●

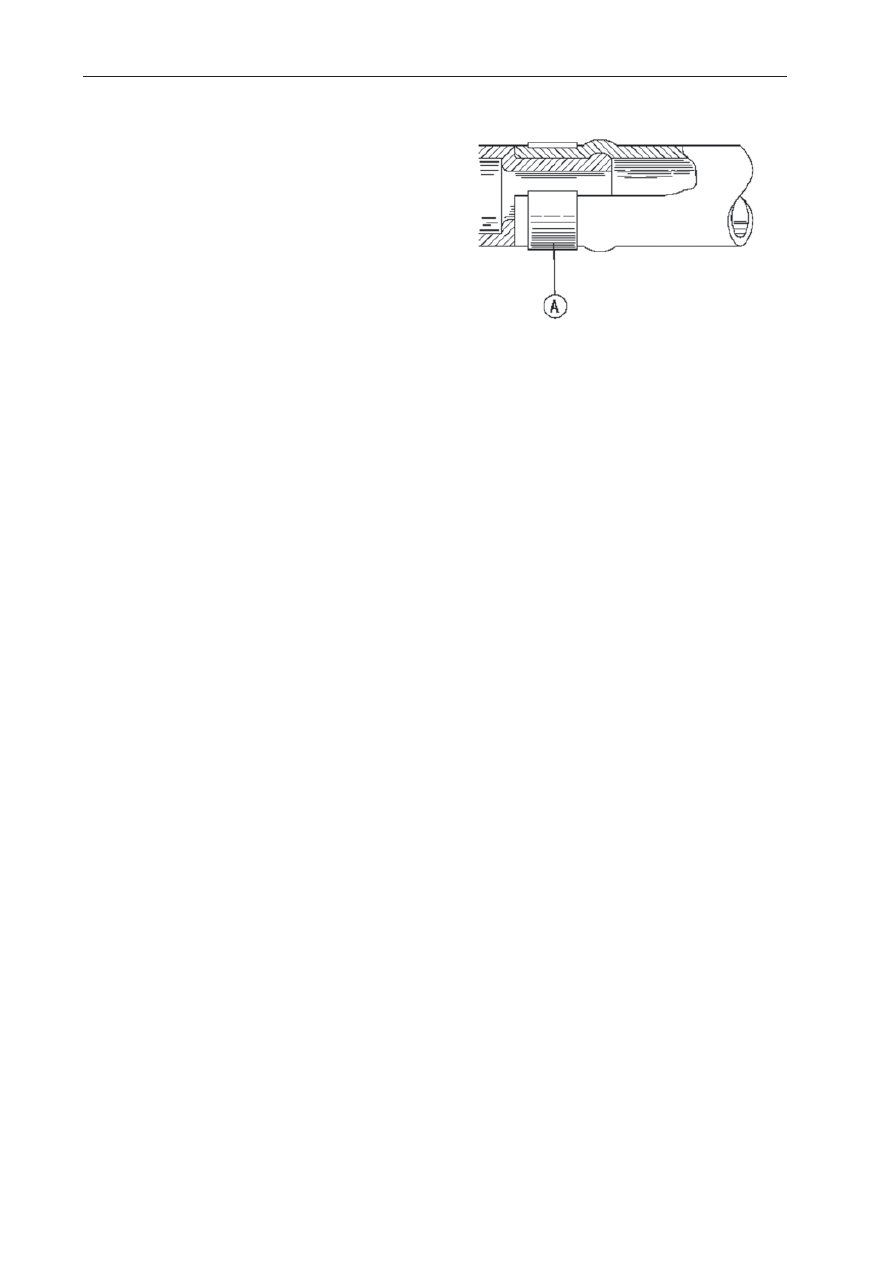

Install the clamp [A] as near as possible to the

hose end to clear the raised rib of the

fi

tting. This

will prevent the hoses from working loose.

○

The clamp screws should be positioned correctly

to prevent the clamps from contacting the other

parts.

Torque - Radiator Hose Clamp Screws: 2.0

N·m (0.20 kgf·m, 17 in·lb)

Hose Inspection

●

Refer to the Radiator Hose Damage and

Installation Condition Inspection in the Periodic

Maintenance chapter.