CFMoto motorcycle CF650NK. Service Manual - part 17

FUEL SYSTEM (EFI) 3-65

Fuel Pump

Fuel Pump Installation

Remove dirt or dust from the fuel pump [B] by lightly

applying compressed air.

Replace the fuel pump gasket [C] with a new one if

damaged.

Tighten the fuel pump bolts to a snug fit, tighten

them in a crisscross pattern.

Torque - Fuel Pump Bolts: 5 N

m

Tighten the pump bolts again in a crisscross pat-

tern to check the tightness.

Fuel Pump Operation Inspection

NOTE

O

Be sure the battery is fully charged.

O

Just listen to the pump sound in the fuel tank to

confirm pump operation.

Turn the ignition switch ON and make sure that the

fuel pump operates (make light sounds) for 3

seconds, and then stops.

Turn the ignition switch OFF.

If the pump does not work as described above, in-

spect the operating voltage.

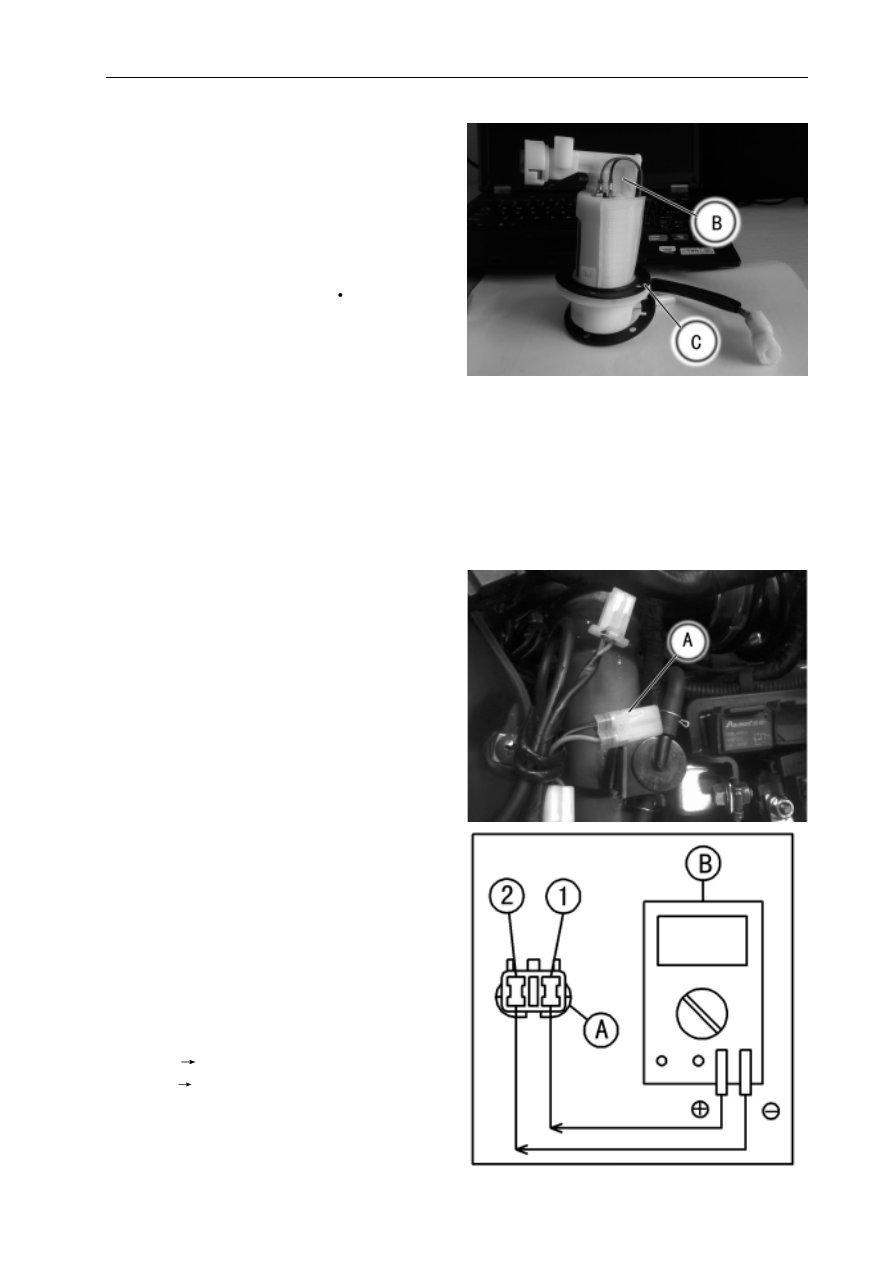

Fuel Pump Operation Inspection

NOTE

O

Be sure the battery is fully charged.

Turn the ignition switch OFF.

Remove the fuel tank.

Disconnect the fuel pump connector[A].

Measure the operating voltage with the engine

stopped.

Turn the ignition switch ON.

The tester needle should indicate battery voltage for

3 seconds, and then 0 V.

Connections to Pump Connectors:

Tester(+)

terminal 1(lead B/Y)

Tester(-)

terminal 2(lead G)

With the ignition switch ON:

Standard:

Battery Voltage for 3 seconds, and then 0 V.