CFMoto motorcycle CF150-A. Service Manual - part 6

5-14

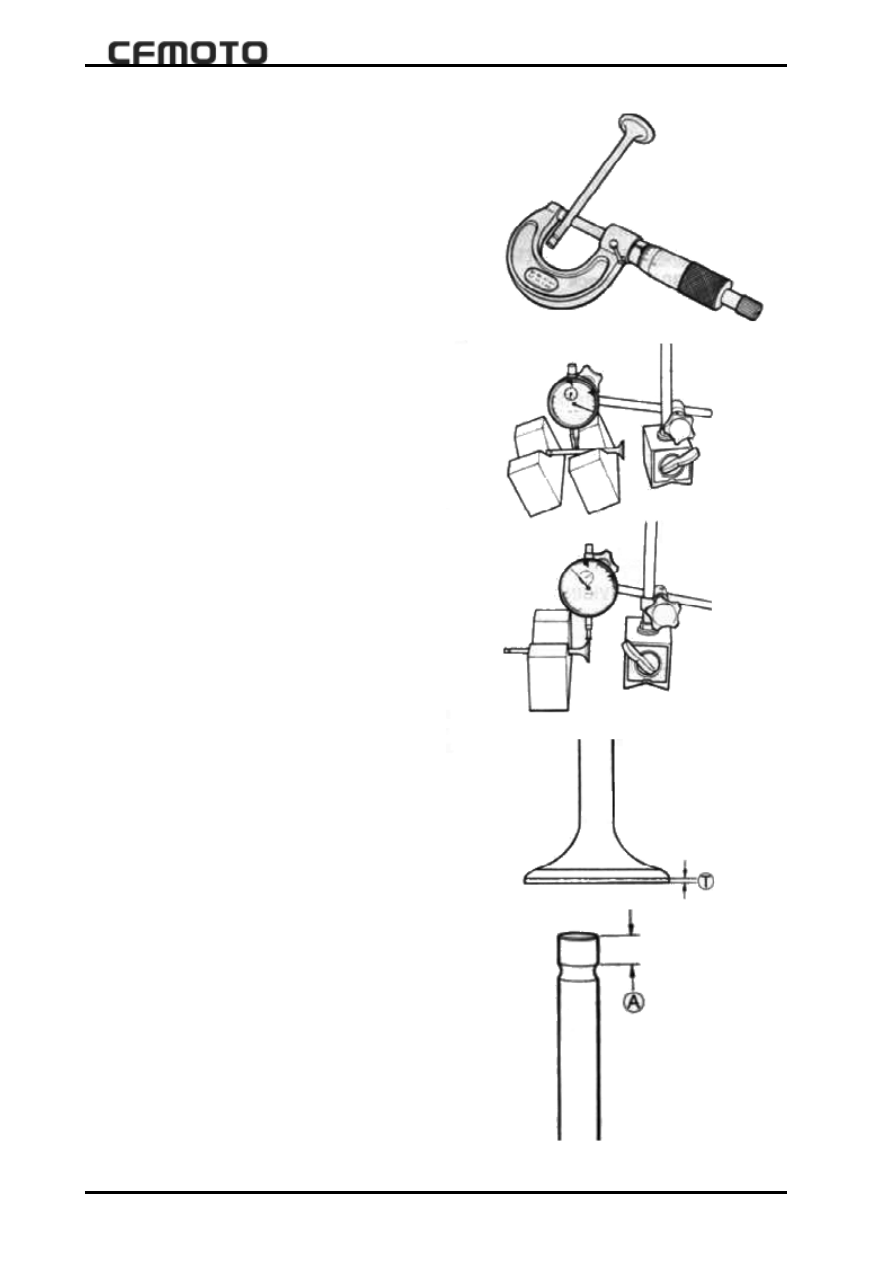

Valve stem jump

z

As illustrated,use a V-shape to support valve,

use a micrometer to measure the jump.

Tool:micrometer and V-shape support

Valve head jump

z

As illustrated,use a micrometer gauge to

meausre valve head jump. If the jump is over

limit,replace valve.

Limit

:0.03

mm

.

Tool:Megnetic clock seat, micrometer gauge

(1/100)and V-shape seat.

Valve head surface wearing

z

Check wearing of every valve head surface,

replace a new valve in case of wearing or

damage.Measure valve head width T, if valve

head depth

is smaller than limit,replace

valve.

Valve head limit

:0.5

mm

Tool:Feeler gauge

External diameter of valve stem

z

Measure with a micrometergauge

Valve intake

4.975-4.990

mm

Valve exhaust

4.955-4.970

mm

Tool:Micrometer gauge

(0-25

mm

)

Valve step end status

z

Check valve step end surface for corrosion

and wearing. If A is less than the limit,repair

it.

Valve stem length limit

:4.5

mm

Tool:feeler gauge;