Hyundai Excavator R210LC-7. Service and repair manual - page 38

8-133

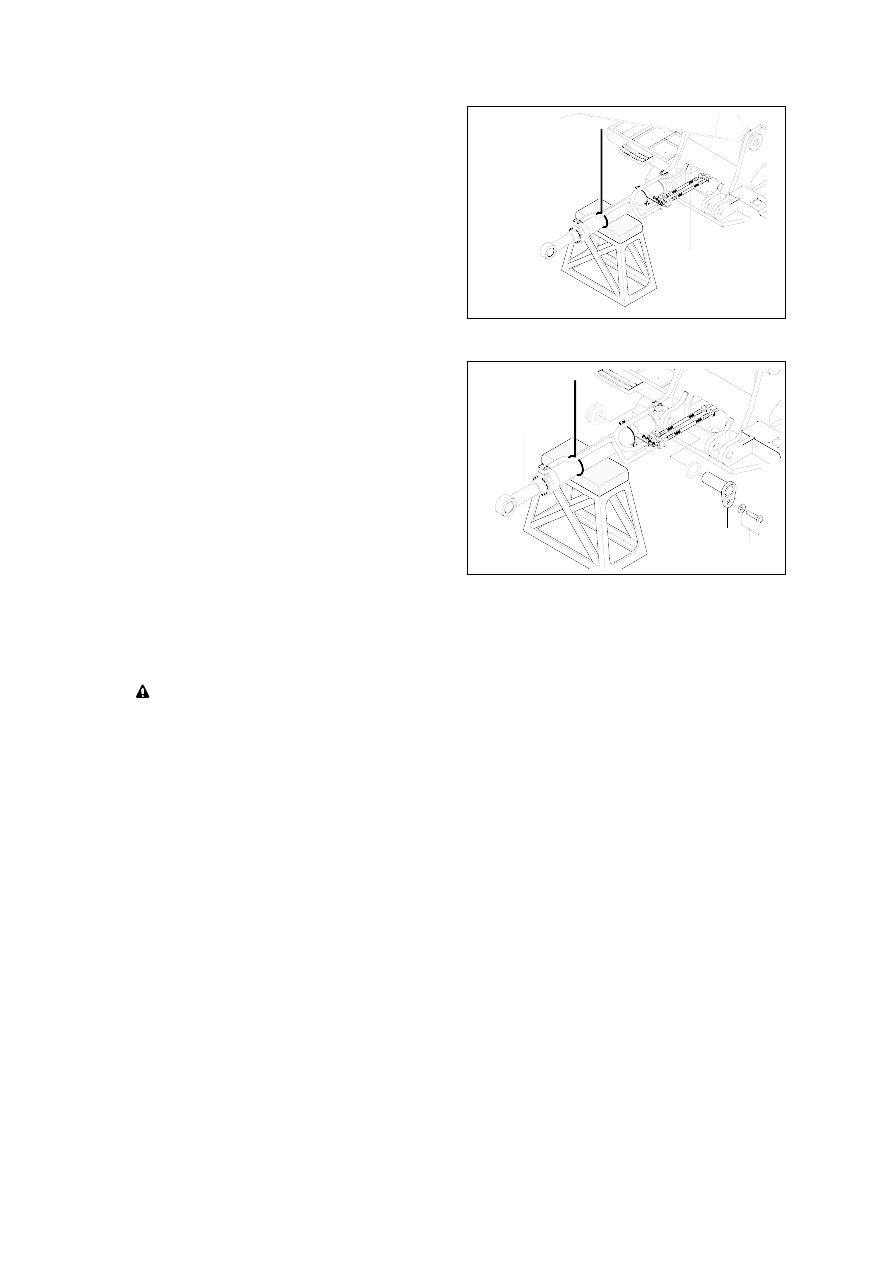

7

8

9

6

Install

Carry out installation in the reverse order

to removal.

When aligning the mounting position of

the pin, do not insert your fingers in the

pin hole.

Bleed the air from the boom cylinder.

Conformed the hydraulic oil level and

check the hydraulic oil leak or not.

(2)

Remove bolt(9) and pull out pin(8).

Remove boom cylinder assembly(6).

Weight : 182kg(386lb)

Disconnect boom cylinder hoses(7) and

put plugs on cylinder pipe.