Hyundai Excavator R210LC-7. Service and repair manual - page 17

5 - 24

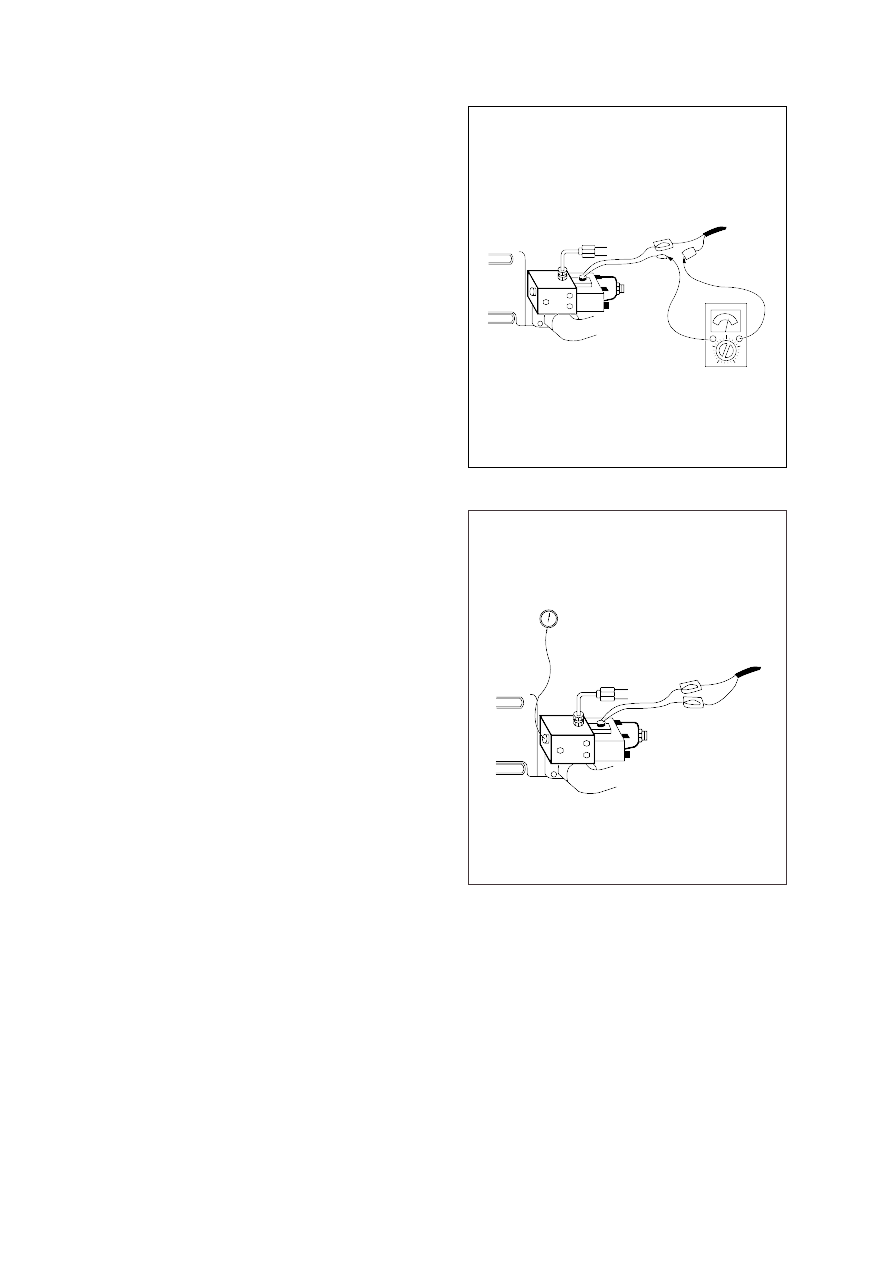

3. EPPR VALVE CHECK PROCEDURE

CHECK ELECTRIC VALUE AT EPPR VALVE

Start engine.

Set S-mode and cancel auto decel mode.

Position the accel dial at 10.

If tachometer show approx 2150 50rpm,

2050 50rpm(TIER II) disconnect one

wire harness from EPPR valve.

Install multimeter as figure.

Check electric current at bucket circuit

relief position.

CHECK PRESSURE AT EPPR VALVE

Remove plug and connect pressure

gauge as figure.

Gauge capacity : 0 to 40-50kgf/cm

2

(0 to 580-725psi)

Start engine.

Set S-mode and cancel auto decel mode.

Position the accel dial at 10.

If tachometer show approx 2150 50rpm,

2050 50rpm(TIER II) check pressure at

relief position of bucket circuit by

operating bucket control lever.

If pressure is not correct, adjust it.

After adjust, test the machine.

(1)

(2)

(3)

(4)

(5)

(6)

(1)

(2)

(3)

(4)

(5)

(6)

(7)

1)

2)

Spec : 200~450mA

Spec : 2~25kgf/cm

2

(30~350psi)

5-23(1) (290-7)

5-23(2) (290-7)