Hyundai Excavator R210LC-7. Service and repair manual - page 8

2-64

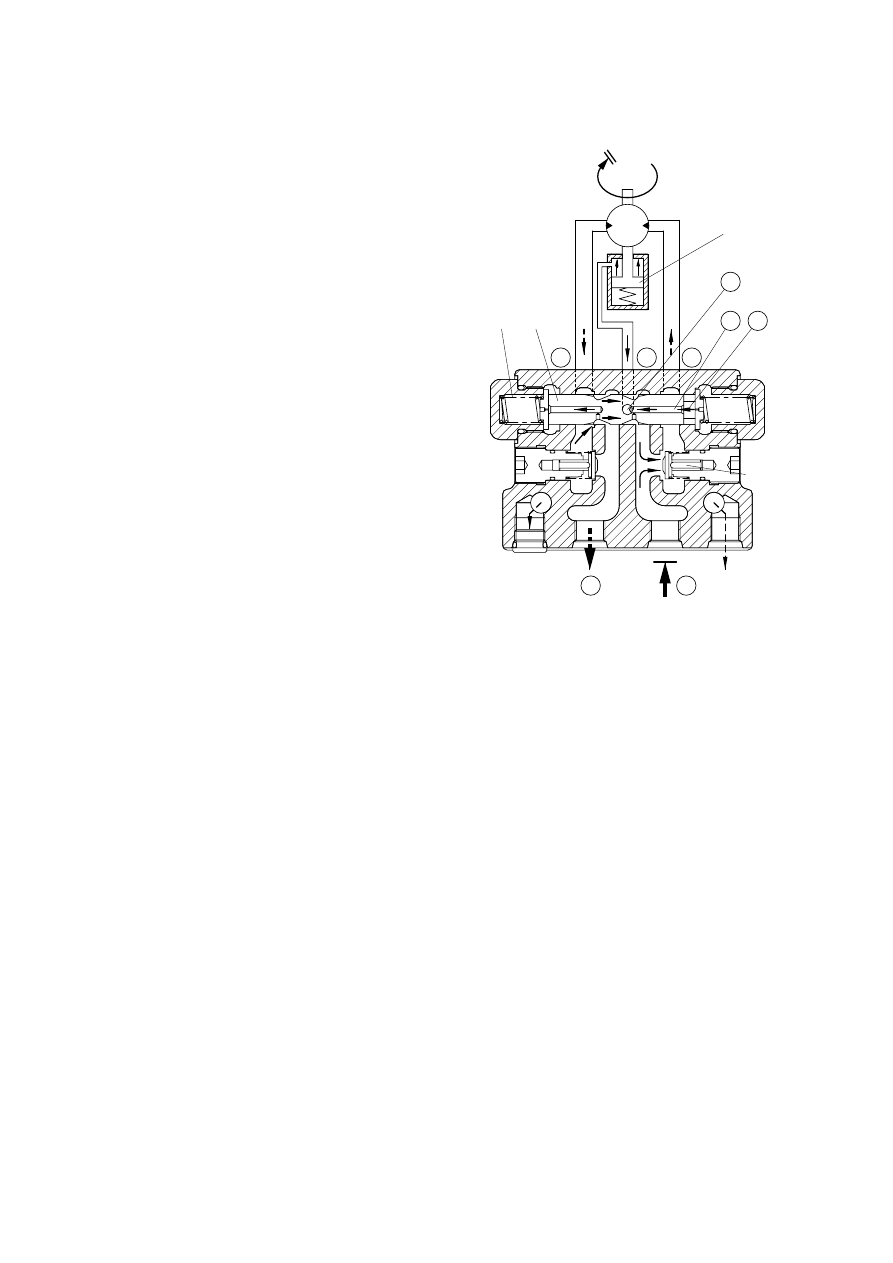

Braking effect on downhill travel

If the machine traveling downhill with a

relatively small supply of high pressure oil

to its travel motors should start coasting,

the same braking effect as the one

described above would automatically

occur.

In the coasting condition, the motor is

driven, instead of driving the track, from

the ground and sucks high pressure oil

in.

In other words, the motor tends to draw

more high pressure oil than is being

supplied.

Under this condition, port A goes

negative to pull oil out of chamber

through oil way

, moving back the

spool(323) rather rapidly.

The clearance on the left then becomes

smaller to throttle the outgoing oil more

than before, thereby obstructing the

pumping action of the motor.

As in stopping the machine, pressure will

build up in port D to make it harder to

drive the motor from the ground: This is

the braking action.

C

E

323

328

D

a

b

327

B

A

Drain

P

112