BMW AG Motorcycle (K1100LT, K1100RS). Manual - part 24

23.21

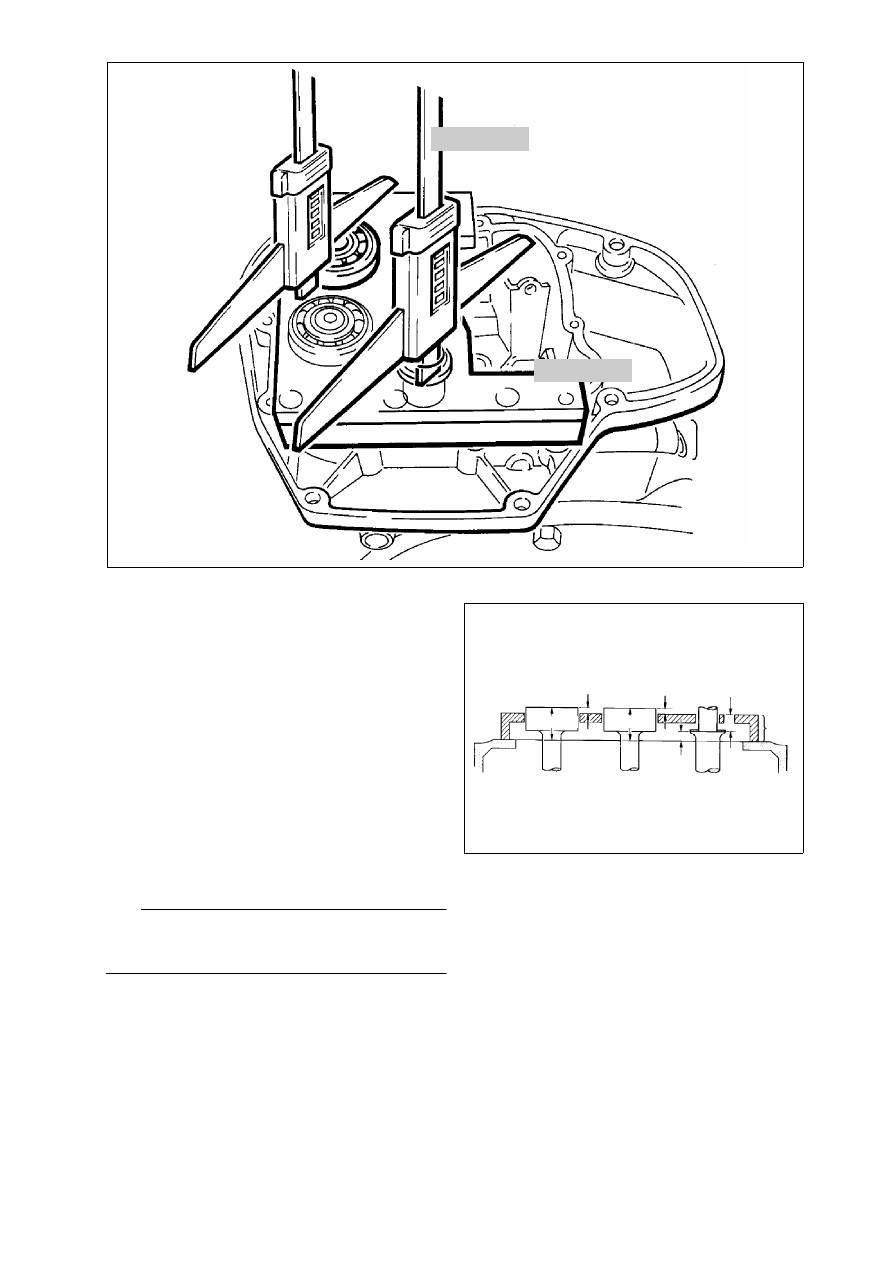

Measuring distances between trans-

mission shafts

Measuring bearing distance of shafts

•

Place transmission measuring plate,

BMW No. 23 3 660 (arrow), on the transmission

housing.

•

Measuring procedure for intermediate shaft and

output shaft:

Using depth gauge,

BMW No. 00 2 550

, meas-

ure distance between ball bearing outer race and

measuring plate. Before measuring, knock the

corresponding shaft to the base of its seat.

•

For the input shaft, measure through the window

in the measuring plate the distance from the

bearing collar to the measuring plate.

•

Enter all measurements in a table, see example.

L

Note:

The dimension for the input shaft must be entered

with a negative sign in the table!

Mab =

Dimension output shaft to measuring plate

Mzw =

Dimension intermediate shaft to measuring

plate

Man =

Dimension measuring plate to collar on input

shaft

H =

Height of measuring plate

Total measurement:

Gab = Mab + H

Gzw = Mzw + H

Gan = H – Man

23 3 660

LT230310

00 2 550

LT230320

Mab

Mzw

Man

Gab

Gzw

Gan

H