BMW AG Motorcycle (K1100LT, K1100RS). Manual - part 8

11.33

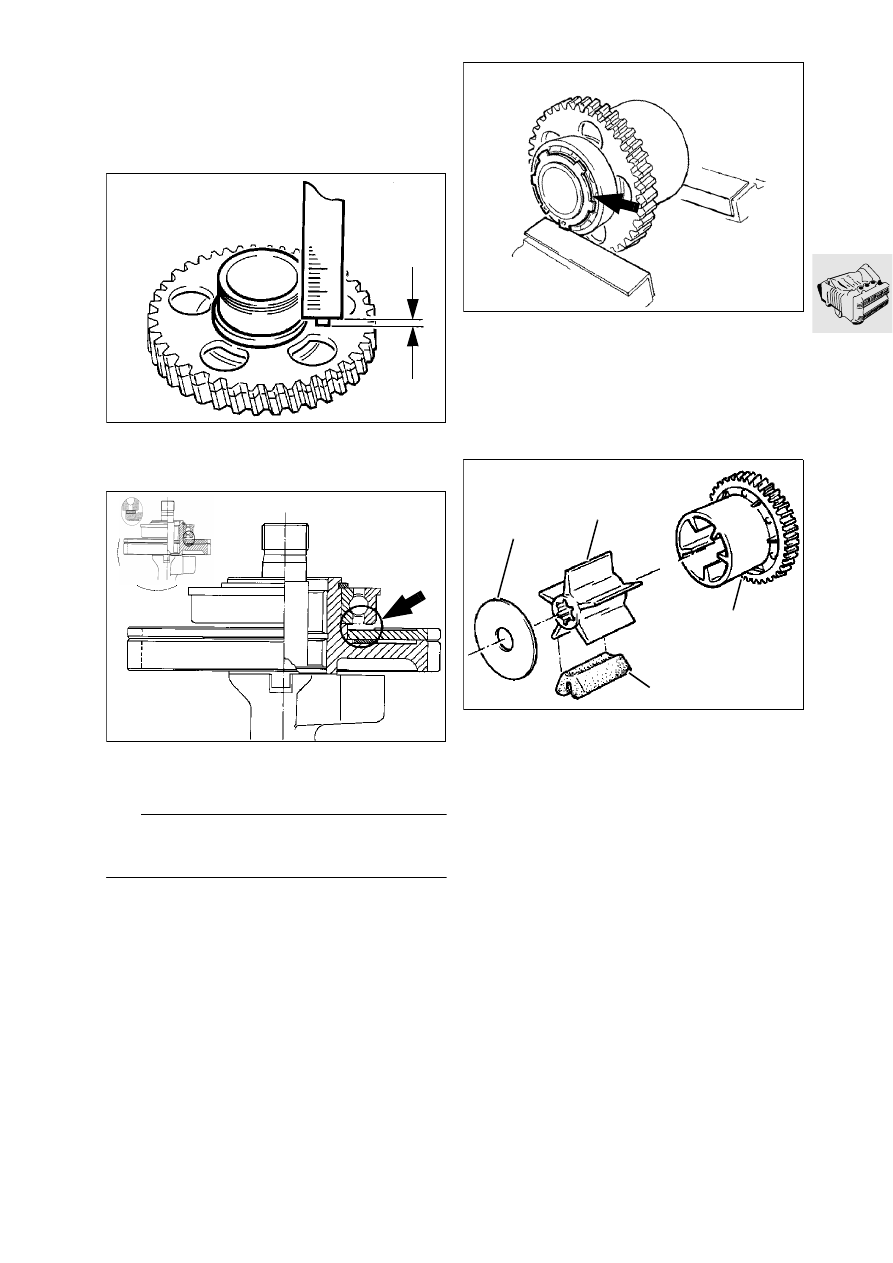

Assembling tensioning gear

•

Insert the tensioning spring.

•

Install tensioning gear with counter-holder,

BMW No. 12 4 600.

•

Clamp the tensioning gear with damper housing

together into a vice with soft jaws.

•

Measure distance “a” from ball bearing seat to

tensioning gear.

•

Place a suitable spacing washer (arrow) on the

tensioning gear.

L

Note:

The thickness of the spacing washer must never ex-

ceed this measurement.

•

Heat the ball bearing to 80 °C and install it (with

shoulder upwards).

•

Clamp the damper housing and the ball bearing

together in the vice (with soft jaws).

•

Place the circlip (arrow) in the groove in front of

the bearing, using Seeger circlip pliers.

•

The circlip must snap completely into the groove.

Installing damper

•

Insert damper rubbers (1) into damper

housing (2).

•

Push retaining plate (3) on to output shaft; heat

the inner section of damper (4) slightly and press

it on.

•

Push the damper housing on to the output shaft.

a

LT110470

LT110480

LT110490

3

4

2

1

LT110500