Volkswagen Fox (2004 year). Manual - part 13

Special tools and workshop

equipment required

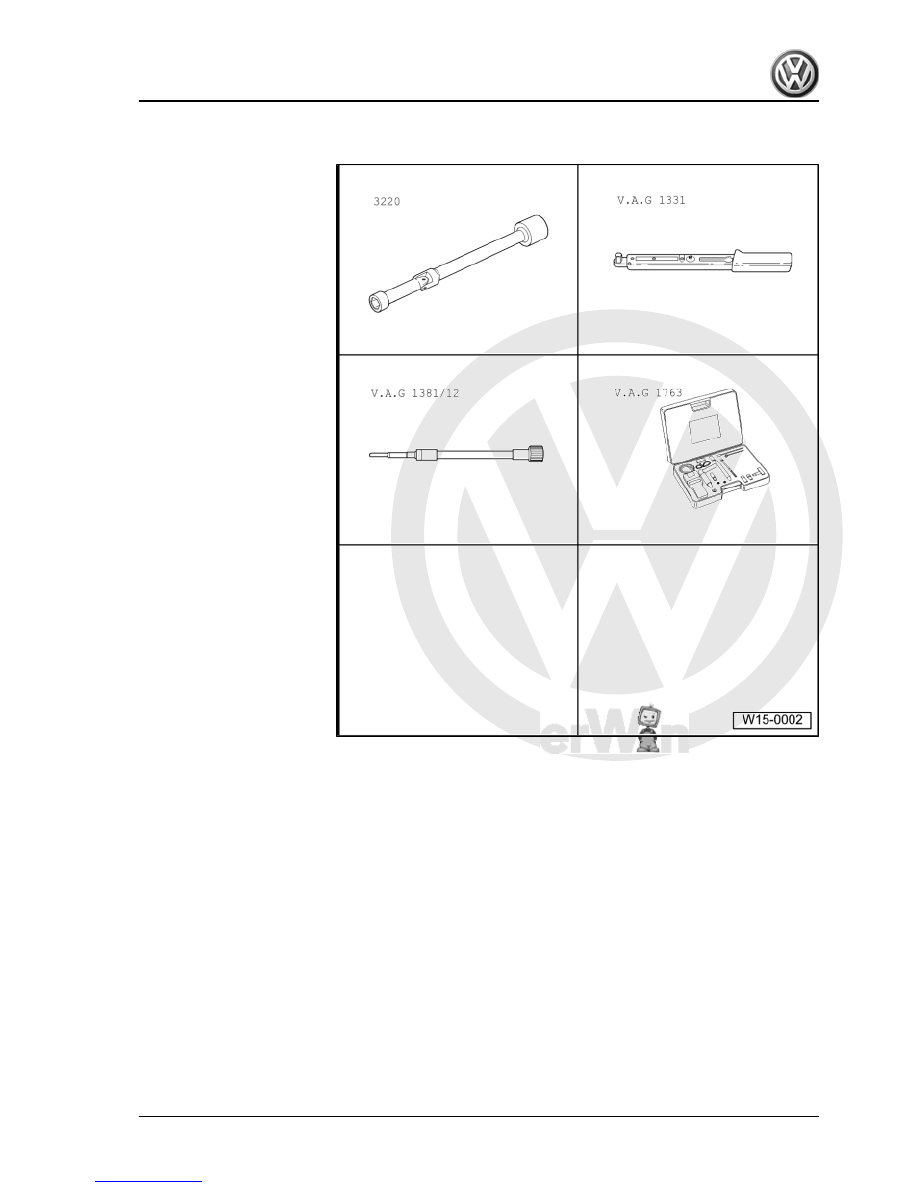

♦ U/J extension and socket,

10 mm -3220-

♦ Torque wrench - 5 to 50 Nm

(enc. 1/2") -VAG 1331-

♦ Adapter -V.A.G 1381/12-

♦ Compression meter -

V.A.G 1763-

Test conditions

• Minimum engine oil temperature 30 °C.

Test sequence

– Remove central connector from unit injectors.

– Remove all glow plugs, using U/J extension and socket, 10

mm -3220- .

Fox 2004 ➤

1. Cylinder head - remove and install

49