Suzuki Grand Vitara JB419. Manual - part 126

Air Conditioning System: 7B-10

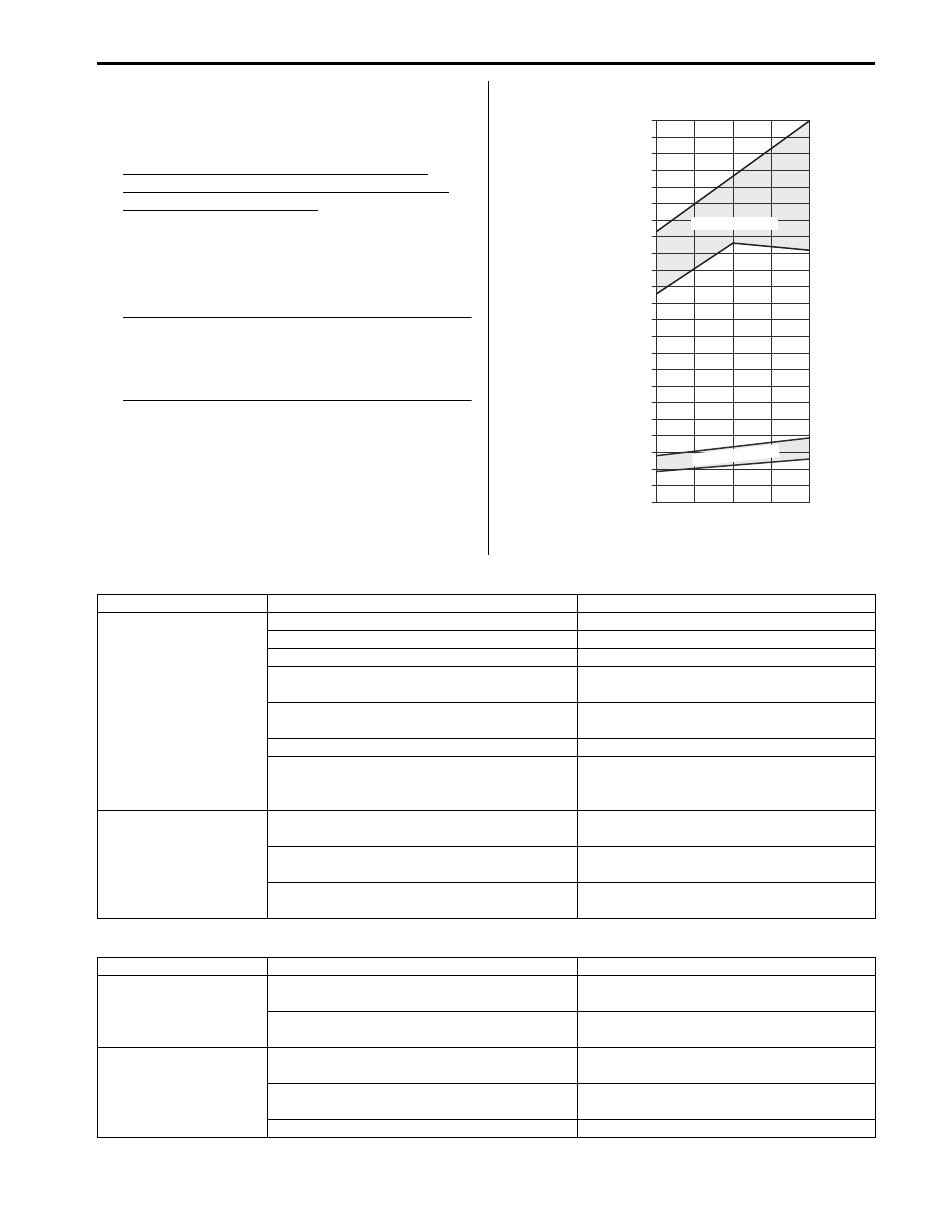

10) Check for each pressure of low side and high side if

it is within shaded range of graph. If each gauge

reading is out of specified pressure, correct defective

part referring to the table.

Low side and high side pressure example,

gauges should read as follows when ambient

temperature is 30

°C (86 °F)

Pressure on high pressure gauge (HI): 1570 –

1970 kPa (15.7 – 19.7 kg/cm

2

, 223 – 280 psi)

Pressure on high pressure gauge (LO): 230 – 330

kPa (2.3 – 3.3 kg/cm

2

, 33 – 47 psi)

NOTE

Pressure registered on gauge varies with

ambient temperature. Therefore, use the

graphs when determining if pressures are

normal or not.

High pressure gauge

Low pressure gauge

14.2

28.4

Pressure of Lo

Pressure Gauge

22

312.9

2200

0

1

23

327.1

2300

2

3

30

70

30

70

%

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

21

298.7

2100

20

42.7

56.9

71.1

85.3

99.5

113.8

128.0

142.2

151.4

170.6

184.9

199.1

213.3

227.5

241.7

256.0

270.2

284.4

100

200

300

400

500

600

700

800

900

1000

1100

1200

1300

1400

1500

1600

1700

1800

1900

2000

25

30

35

77

86

95

psi

kPa kg/cm

2

Ambient Temperature

C

F

w

Pressure of High Pressure

Gauge

“A”

“B”

“C”

“D”

Humidity

Acceptab

le range

Acceptable range

I5JB0B720006-03

Condition

Possible Cause

Correction

Pressure is higher than

acceptable range

(“A” area)

Refrigerant overcharged

Recharge.

Expansion valve frozen or clogged

Check expansion valve.

Clogged refrigerant passage of high side

Clean or replace.

Radiator cooling fan malfunction (Insufficient

cooling of condenser)

Check radiator cooling fan.

Dirty or bent condenser fins (Insufficient

cooling of condenser)

Clean or repair.

Compressor malfunction (Insufficient oil etc.) Check compressor.

Engine overheat

Check engine cooling system referring to

“Engine Cooling Symptom Diagnosis in

Section 1F”.

Pressure is lower than

acceptable range

(“B” area)

Insufficient refrigerant (Insufficient charge or

leakage)

Check for leakage, repair if necessary and

recharge.

Expansion valve malfunction (valve opens too

wide)

Check expansion valve.

Compressor malfunction (Insufficient

compression)

Check compressor.

Condition

Possible Cause

Correction

Pressure is higher than

acceptable range

(“C” area)

Expansion valve malfunction (valve opens too

wide)

Check expansion valve.

Compressor malfunction (Insufficient

compression)

Check compressor.

Pressure is lower than

acceptable range

(“D” area)

Insufficient refrigerant (Insufficient charge or

leakage)

Check for leakage, repair if necessary and

recharge.

Expansion valve malfunction (valve opens too

narrow)

Check expansion valve.

Clogged refrigerant passage (crashed pipe)

Repair or replace.