Suzuki Grand Vitara JB416 / JB420. Manual - part 241

5A-98 Automatic Transmission/Transaxle:

Automatic Transmission Unit Disassembly

S5JB0A5106067

1) Extract torque converter. And remove oil filler tube

and dipstick.

CAUTION

!

Remove torque converter as much straight

as possible. Leaning it may cause damage to

oil seal lip.

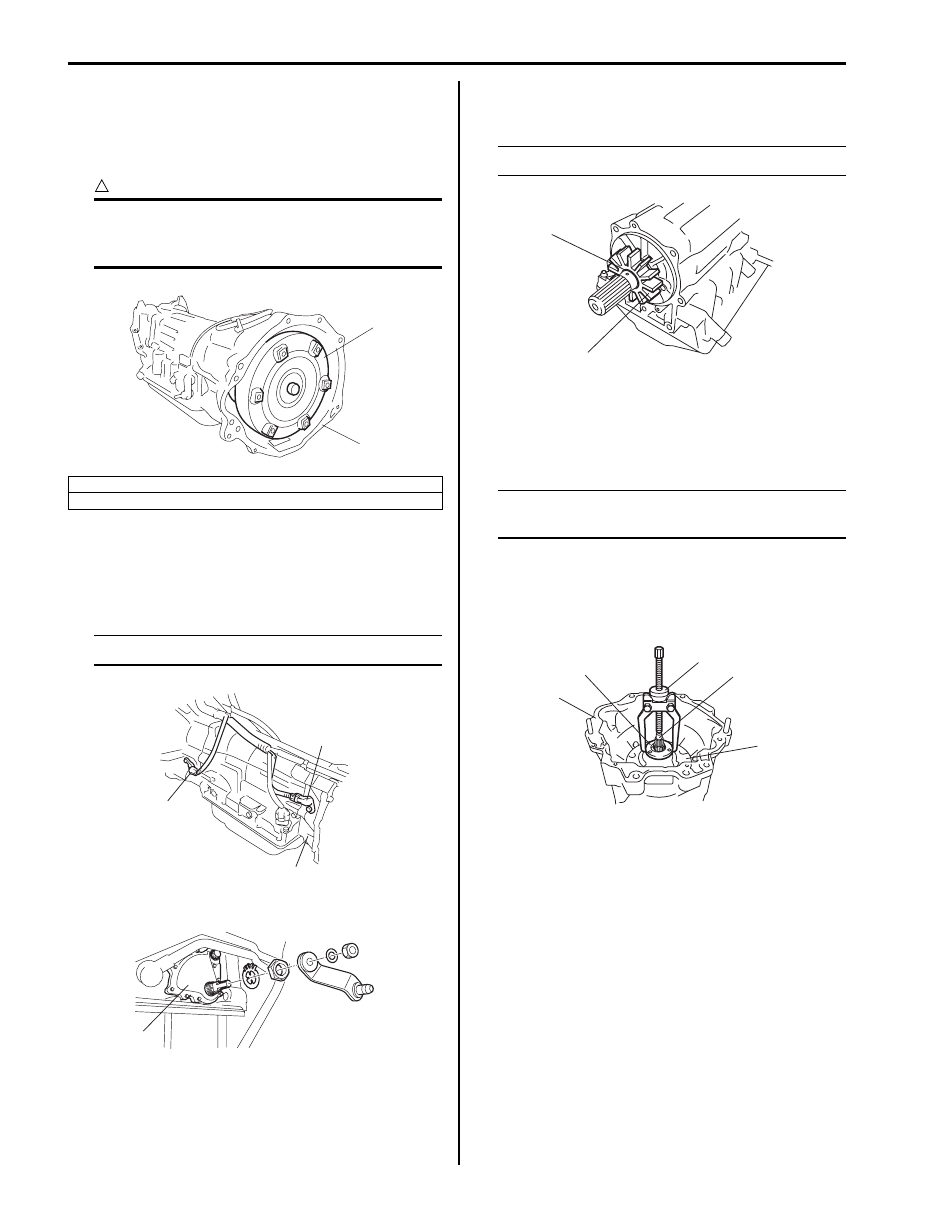

2) Remove input shaft speed sensor (1) and output

shaft speed sensor (2).

3) Remove 6 adapter case fixing bolts and then remove

adaptor case (3) and gasket.

NOTE

Use care not to cause damage to oil seal.

4) Remove shift switch (1).

5) Remove C-ring (1) and then remove speed sensor

rotor (2).

NOTE

Use care not to loose rotor stop key.

6) Remove oil pump (1) by using special tools.

Special tool

(A): 09913–65135

(B): 09927–66520

NOTE

Use care not to cause damage to shaft

bushing surface.

7) Remove bearing at the rear of oil pump (1).

8) Remove O-ring from oil pump (1).

9) Holding input shaft (2) by hand, remove converter

housing (3).

1. Torque converter

2. Converter housing

1

2

I5JB0A510069-01

1

2

3

I5JB0A510070-02

1

I5JB0A510071-01

1

2

I5JB0A510072-01

3

(B)

(A)

2

1

I5JB0A510073-01