Suzuki Grand Vitara JB416 / JB420. Manual - part 135

1I-8 Starting System:

Brush Spring

Inspect brush springs for wear, damage or other

abnormal conditions. Replace if necessary.

Brush spring tension

Standard: 1.8 kg (3.97 lb)

Limit: 0.3 kg (0.67 lb)

Brush Holder

• Check movement of brush in brush holder. If brush

movement within brush holder is sluggish, check

brush holder for distortion and sliding faces for

contamination. Clean or correct as necessary.

• Check for continuity across insulated brush (positive

side) and grounded brush (negative side). If continuity

exists, brush holder is grounded due to defective

insulation and should be replaced.

Armature

• Inspect commutator for dirt or burn. Correct with

sandpaper or lathe, if necessary.

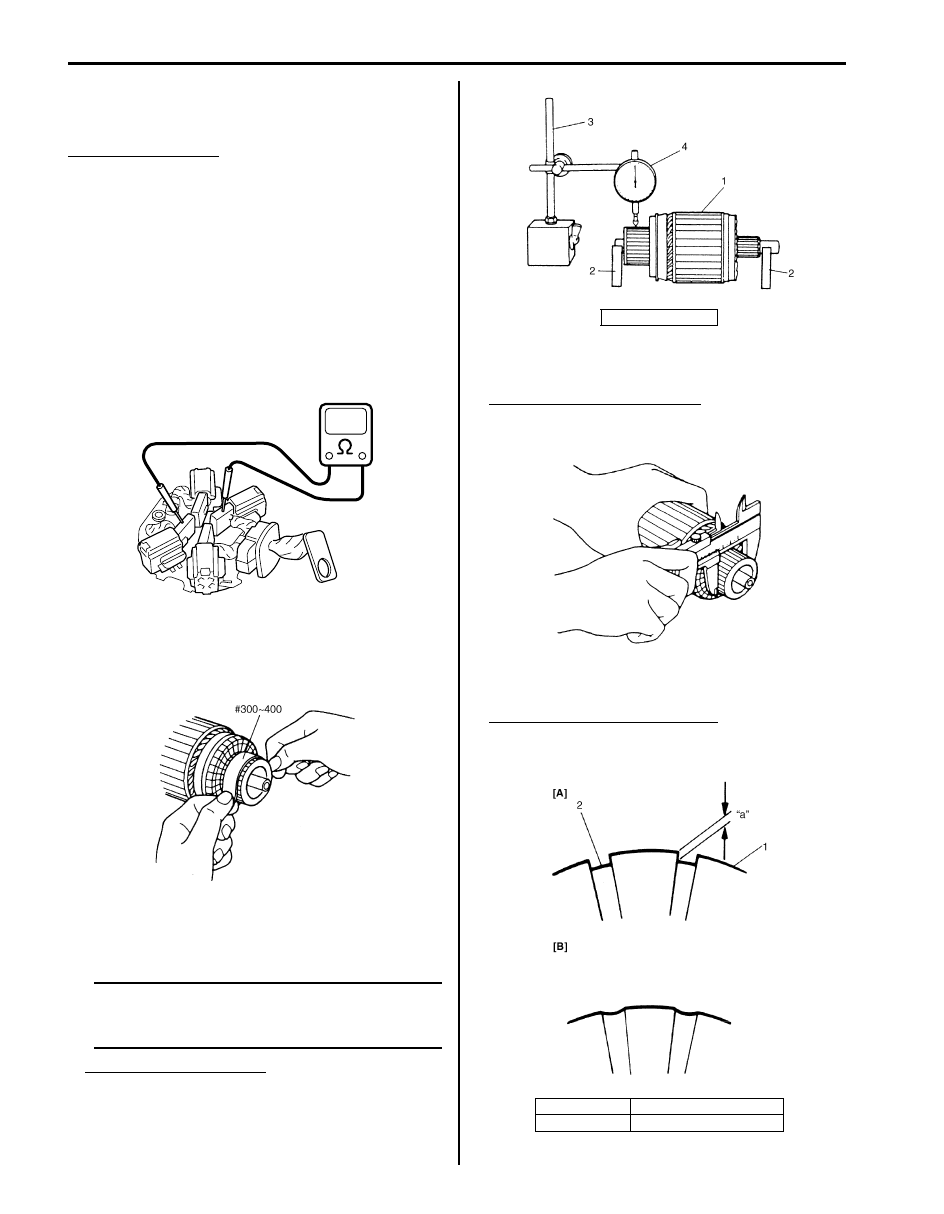

• Check commutator for uneven wear with armature (1)

supported on V-blocks (2). If deflection of dial gauge

(4) pointer exceeds limit, repair or replace.

NOTE

The following specification presupposes that

armature is free from bend. Bent armature

must be replaced.

Commutator out of round

Standard: 0.05 mm (0.002 in.) or less

Limit: 0.4 mm (0.016 in.)

• Inspect commutator for wear. If diameter is below

limit, replace armature.

Commutator outside diameter

Standard: 29.4 mm (1.16 in.)

Limit: 28.8 mm (1.13 in.)

• Inspect commutator for insulator depth. Correct or

replace if below limit.

Commutator insulator depth “a”

Standard: 0.4 – 0.6 mm (0.016 – 0.024 in.)

Limit: 0.2 mm (0.008 in.)

I4RS0A190004-01

IYSQ01190034-01

3. Magnetic stand

[A]: Correct

1. Commutator segment

[B]: Incorrect

2. Insulator

IYSQ01190035-01

IYSQ01190036-01

I5JB0A190003-01