Suzuki Grand Vitara JB416 / JB420. Manual - part 134

1I-4 Starting System:

Starting Motor Performance Test

S5JB0A1904002

CAUTION

!

Each test must be performed within 3 – 5

seconds to avoid coil from burning.

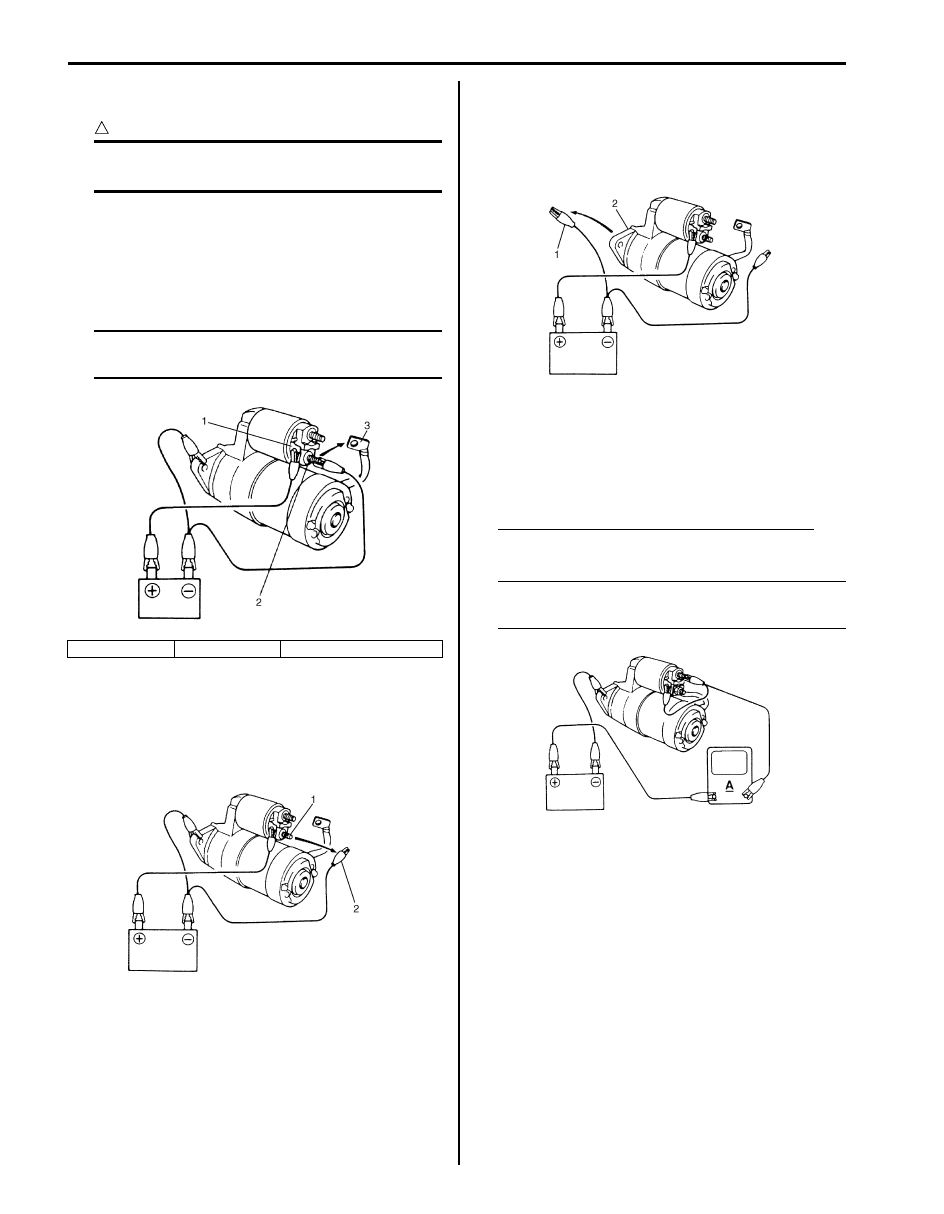

Pull-In Test

1) Connect battery to magnetic switch as shown.

2) Check that plunger and pinion move outward. If

plunger and pinion don’t move, replace magnetic

switch.

NOTE

Before testing, disconnect lead wire from

terminal “M”.

Hold-In Test

1) While connected as above with plunger out,

disconnect negative lead (2) from terminal “M” (1).

2) Check that plunger and pinion remain out. If plunger

and pinion return inward, replace magnetic switch.

Plunger and Pinion Return Test

1) Disconnect negative lead (1) from switch body (2).

2) Check that plunger and pinion return inward. If

plunger and pinion don’t return, replace the magnetic

switch.

No-Load Performance Test

1) Connect battery and ammeter to starter as shown.

2) Check that starter rotates smoothly and steadily with

pinion moving out. Check that ammeter indicates

specified current.

Specified current (no-load performance test)

90 A MAX. at 11 V

NOTE

Use wires as thick as possible and tighten

each terminal fully.

1. Terminal “S”

2. Terminal “M”

3. Lead wire (switch to motor)

IYSQ01190003-01

IYSQ01190004-01

IYSQ01190005-01

IYSQ01190006-01