Suzuki Grand Vitara JB416 / JB420. Manual - part 36

1A-93 Engine General Information and Diagnosis:

DTC Confirmation Procedure

WARNING

!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and tester, on a level road.

NOTE

Check to make sure that following conditions are satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10

°C (14 °F) to 80 °C (176 °F)

• Intake air temperature: –10

°C (14 °F) to 70 °C (158 °F)

• Altitude (barometric pressure): 2400 m, 8000 ft or less (560 mmHg, 75 kPa or more)

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch, clear DTC.

3) Start engine.

4) Drive vehicle at 40 mph (60 km/h) or higher for 20 min. or more.

5) Stop vehicle.

6) Check DTC and pending DTC.

DTC Troubleshooting

NOTE

Before this trouble shooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions For DTC Troubleshooting”.

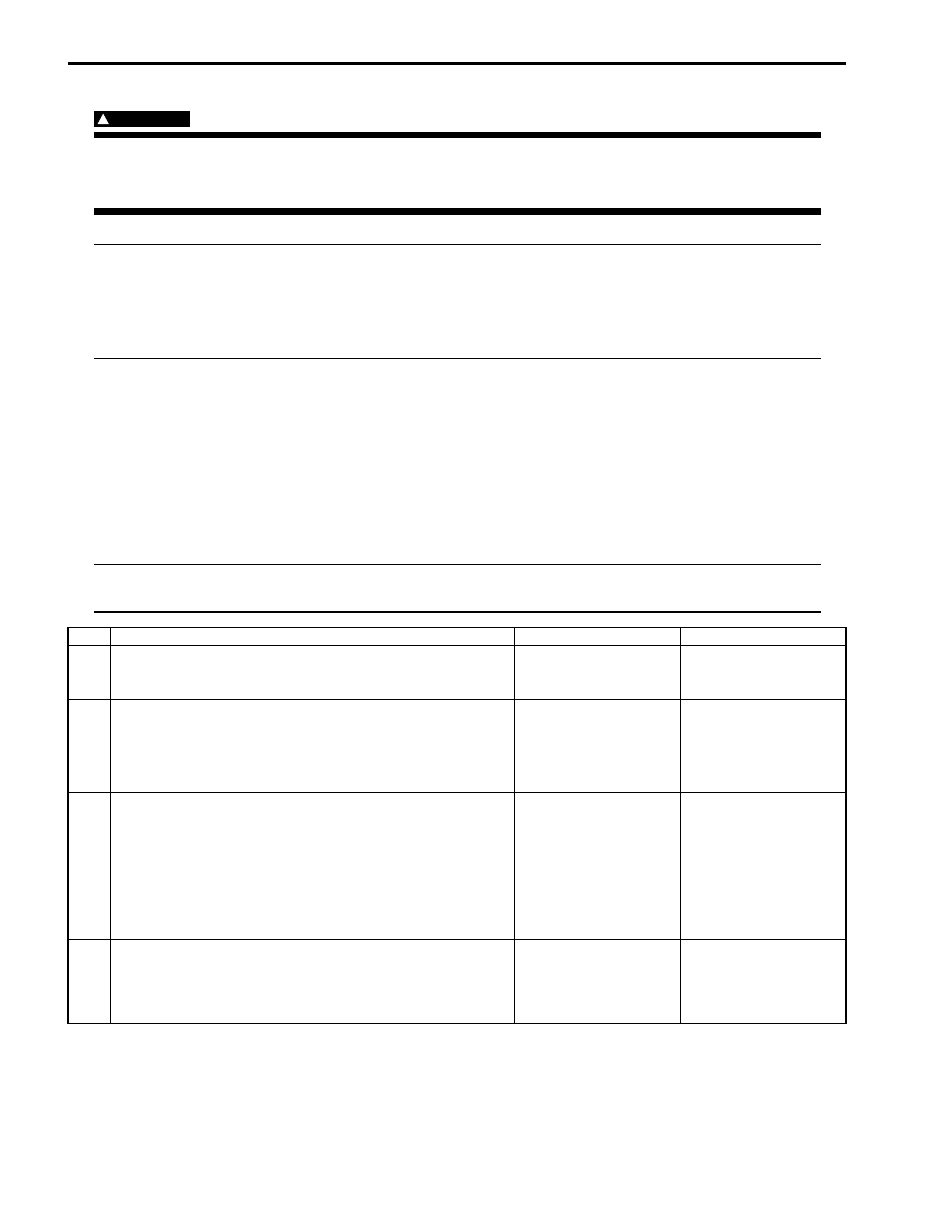

Step

Action

Yes

No

1

Was “Engine and Emission Control System Check”

performed?

Go to Step 2.

Go to “Engine and

Emission Control

System Check”.

2

DTC check

1) With ignition switch turned OFF, install scan tool to DLC.

2) Turn ON ignition switch and check DTC with scan tool.

Is DTC P0118 displayed?

Go to “DTC P0118:

Engine Coolant

Temperature Circuit

High”.

Go to Step 3.

3

Engine coolant temp. check

1) Turn ON ignition switch and check engine coolant temp.

displayed on scan tool.

2) Warm up engine to normal operating temp. and check

engine coolant temp. displayed on scan tool.

Does engine coolant temp. vary more than 1

°

C (1

°

F) and

rise higher than 70

°

C (158

°

F)?

Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Go to Step 4.

4

Thermostat check

Is there a symptom due to thermostat remaining open (it

takes a long time before vehicle heater becomes effective or

before engine is warmed to normal operating temp., etc.)?

Check thermostat

referring to “Thermostat

Inspection in Section

1F”.

Go to Step 5.