Dacia Solenza (engine E7J). Manual - part 122

62

AIR CONDITIONING

62- 14

Pressure controller

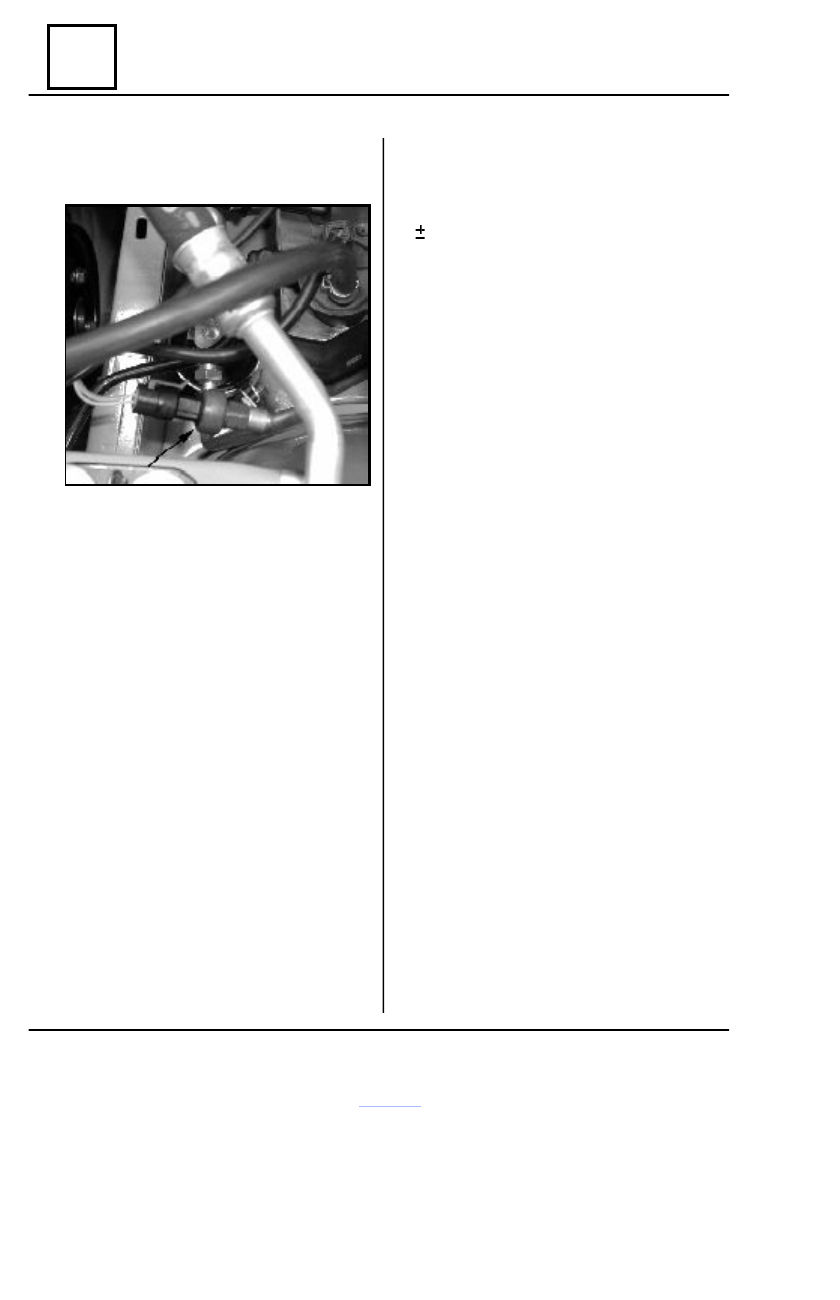

LOCATION

Pressure controller (1) is located on the high-

pressure pipe, near the dryer reservoir.

FUNCTION

The pressure controller is permanently

informing UCE (electronic control unit) about

the circuit pressure.

Subject to pressure value in the high-

pressure circuit, UCE is commanding:

-

circuit break ( by uncoupling the compressor

clutch) when the pressure in the circuit is

decreasing under 1,96 + /-0,2 bar and clutch

coupling when the pressure is over 2,16 +/-

0,2 bar;

-

circuit break when the pressure in the circuit

is over 31,4 +/- 2 bar and compressor clutch

coupling when the pressure is decreasing under

25,5 +/- 2 bar;

-

engine fan starting on second speed, when

the pressure is over 17,7 +/- 1 bar and engine

fan stopping when the pressure is decreasing

under 13.7 +/- 1 bar.

REPLACEMENT

The pressure controller replacement does

not imply the draining of the refrigerant circuit.

Disconnect the pressure controller

connector.

Replace the pressure controller.

When mounting, lubricate the pressure

controller sealing gasket with oil PAG SP 10.

T ighten the pressure controller to the required

moment of 0,9 +/- 0,1 daNm.

Check for refrigerant fluid leaks.

1