Dacia Solenza (engine E7J). Manual - part 100

41

41 - 4

LOWER STRUCTURE

1

Rear longitudinal girder

REPLACEMENT

This operation shall be performed only on the repair/checking bench.. For the specific sup-

ports mounting on the bench, please see the 40 chapter.

DISMOUNTIN

G

Dismount the damaged elements, which are

in contact with the rear longitudinal girder.

Proceed to a straightening on the body

checking/ straightening until bringing the ve-

hicle as closed as possible to the initial shape.

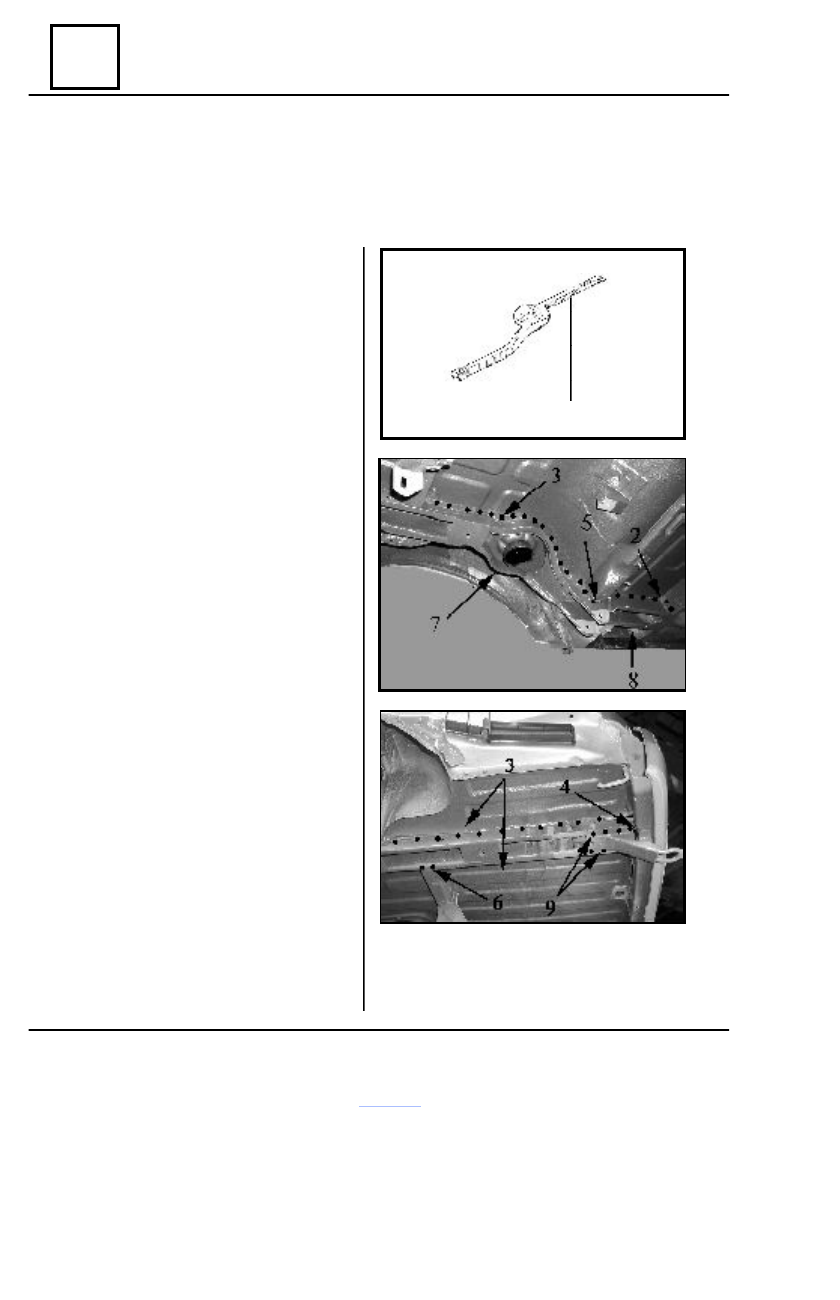

Detach the welding points of the rear

longitudinal girder (1), which are in contact

with:

- central floor in the area (2);

- rear floor in the area (3);

- rear extreme cross member in the area (4);

- tank front cross member in the area (5);

- tank rear cross member in the area (6);

- inner wheel passage in the area (7);

- rear towing hock in the area (9).

Detach the welding points between the rear

side cross member, rear floor and threshold

closing plate in the area (8).

Straighten the areas resulted after dismounting.

Grind the areas resulted after dismounting.

REMOUNTING

Position and center the new element by

means of the repairing bench.

Weld the rear longitudinal girder following

the assembling outlines 2,3,4,5,6,7, 8 and

9(spots and under gas protection welding)

Grind the performed welding.

Protect the performed welding with an

anticorrosive product.

Protect the replaced element with a noise

absorbent product.

Mount the connection elements by

performing the dismounting operations in the

reverse order.