Dacia Solenza (engine E7J). Manual - part 47

19

19 - 1

COOLING - EXHAUST - TANK

COOLING FLUID QUANTITY AND QUALITY

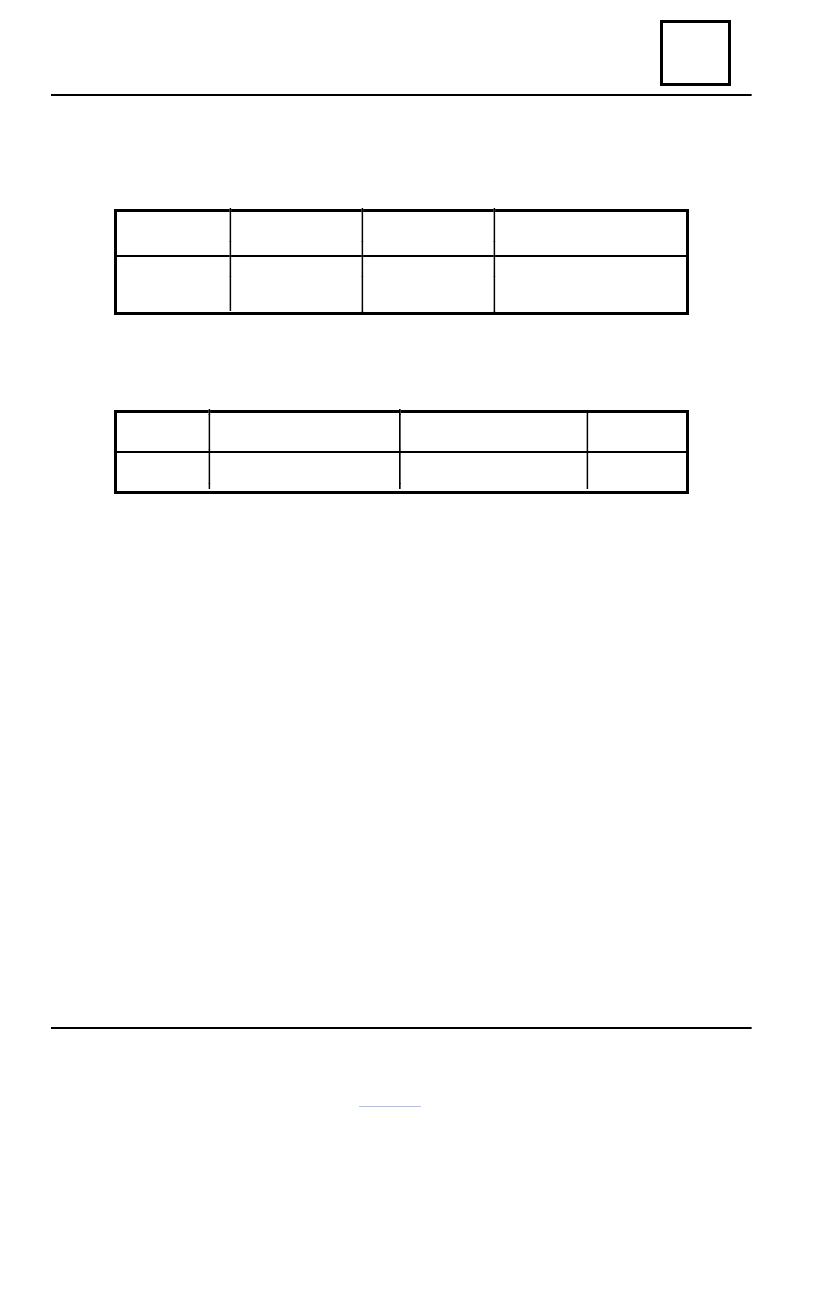

Characteristics

ENGINE

QUANTITY* (liters)

QUALITY

CHARACTERISTICS

E7J

6

Antifreeze type D

Protection until –40°C

GLACEOL RX

〈

Mixture : 50% concentrated antifreeze + 50% distilled water.

THERMOSTAT

ENGINE TYPE

OPENING START (°C)

OPENING

END (°C)

STROKE

(mm)

F8Q

89

101

7.5