содержание .. 28 29 30 31 ..

Peugeot 405. Manual - part 30

Refitting

8 Refitting is a reversal of the removal

procedure, noting the following points:

a) Prior to refitting, fit a new rubber sealing

ring to the sender unit.

b) Refit the sender unit to the tank, aligning

its arrow with the centre of the three

alignment marks on the fuel tank. Secure

the sender in position with the locking

ring, and check that the locking ring,

sender unit and fuel tank marks are all

correctly aligned.

c) Ensure that the feed and return hoses are

correctly reconnected and securely

retained by their clips.

6

Fuel tank -

removal and refitting

3

Note: Refer to the warning note in Section 1

before proceeding.

Removal

1 Before removing the fuel tank, all fuel must

be drained from the tank. Since a fuel tank

drain plug is not provided, it is preferable to

carry out the removal operation when the tank

is nearly empty. Before proceeding,

disconnect the battery negative lead and

syphon or hand-pump the remaining fuel from

the tank.

2 Remove the exhaust system and relevant

heat shield(s) as described in Section 16.

3 From underneath the vehicle, disconnect

the handbrake cable at the equaliser bracket.

4 Release the handbrake primary cable from

the clips in the fuel tank. Position the cable

clear of the tank, so that it will not hinder the

removal procedure.

5 Disconnect the wiring connector from the

fuel gauge sender unit, as described in

Section 5.

6 Working at the right-hand side of the fuel

tank, release the retaining clips then

disconnect the filler neck vent pipe and main

filler neck hose from the fuel tank/filler neck.

Where necessary, also disconnect the

breather hose(s). Some breather hoses are

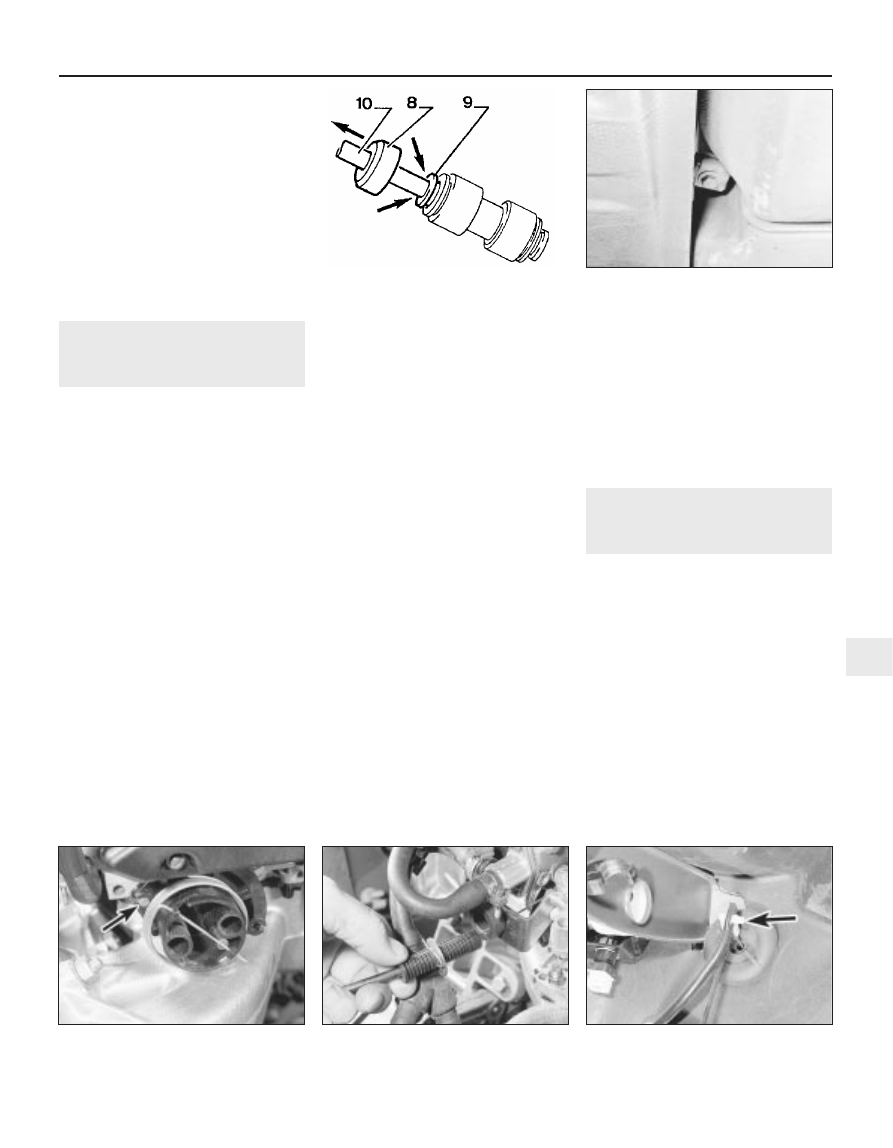

joined to the tank with quick-release fittings; to

disconnect these fittings, slide the cover along

the hose then depress the centre ring and pull

the hose out of its fitting (see illustration).

7 Trace the fuel feed and return hoses back

from the right-hand side of the tank to their

union with the fuel pipes. Slacken the

retaining clips and disconnect both hoses

from the fuel pipes. Where the crimped-type

Peugeot hose clips are fitted, cut the clips and

discard them; use standard worm-drive hose

clips on refitting. Plug the hose and pipe ends,

to prevent the entry of dirt into the system.

8 Place a trolley jack with an interposed block

of wood beneath the tank, then raise the jack

until it is supporting the weight of the tank.

9 Slacken and remove the retaining nut and

bolts, then remove the two support rods from

the underside of the tank (see illustration).

10 Slowly lower the fuel tank out of position,

disconnecting any other relevant vent pipes as

they become accessible (where necessary),

and remove the tank from underneath the car.

11 If the tank is contaminated with sediment

or water, remove the sender unit (Section 5),

and swill the tank out with clean fuel. The tank

is injection-moulded from a synthetic material

- if seriously damaged, it should be renewed.

However, in certain cases, it may be possible

to have small leaks or minor damage repaired.

Seek the advice of a specialist before

attempting to repair the fuel tank.

Refitting

12 Refitting is the reverse of the removal

procedure, noting the following points:

a) When lifting the tank back into position,

take care to ensure that none of the hoses

become trapped between the tank and

vehicle body.

b) Ensure that all pipes and hoses are

correctly routed, and securely held in

position with their retaining clips.

c) Reconnect the handbrake cables and

adjust the handbrake (see Chapter 9).

d) On completion, refill the tank with a small

amount of fuel, and check for signs of

leakage prior to taking the vehicle out on

the road.

7

Accelerator cable - removal,

refitting and adjustment

2

Removal

1 Working in the engine compartment, free

the accelerator inner cable from the

carburettor throttle cam, then pull the outer

cable out from its mounting bracket rubber

grommet (see illustrations). Where fitted,

slide the flat washer off the end of the cable,

and remove the spring clip.

2 Working back along the length of the cable,

free it from any retaining clips or ties, noting

its correct routing.

3 Where necessary remove the lower trim

from below the driver’s side of the facia panel.

4 Working from inside the vehicle, disconnect

the cable from the accelerator pedal by

depressing the lugs on the plastic end fitting

and pushing the fitting from the pedal (see

illustration).

Fuel/exhaust systems - carburettor models 4A•5

7.1a Accelerator cable connection on the

throttle quadrant (arrowed)

8 Cover 9 Centre ring 10 Hose

7.4 Accelerator cable connection to

accelerator pedal (arrowed)

7.1b Outer cable end fitting

6.9 Fuel tank support strap bolt

4A

6.6 Tank breather quick-release connector