Content .. 1516 1517 1518 1519 ..

Nissan Altima L32. Manual - part 1518

TM-416

< ON-VEHICLE MAINTENANCE >

[CVT: RE0F10A]

CVT FLUID

ON-VEHICLE MAINTENANCE

CVT FLUID

Inspection

INFOID:0000000004201992

CHECKING CVT FLUID

Fluid level should be checked with the fluid warmed up to 50

° to 80°C (122° to 176°F). The fluid level check

procedure is as follows:

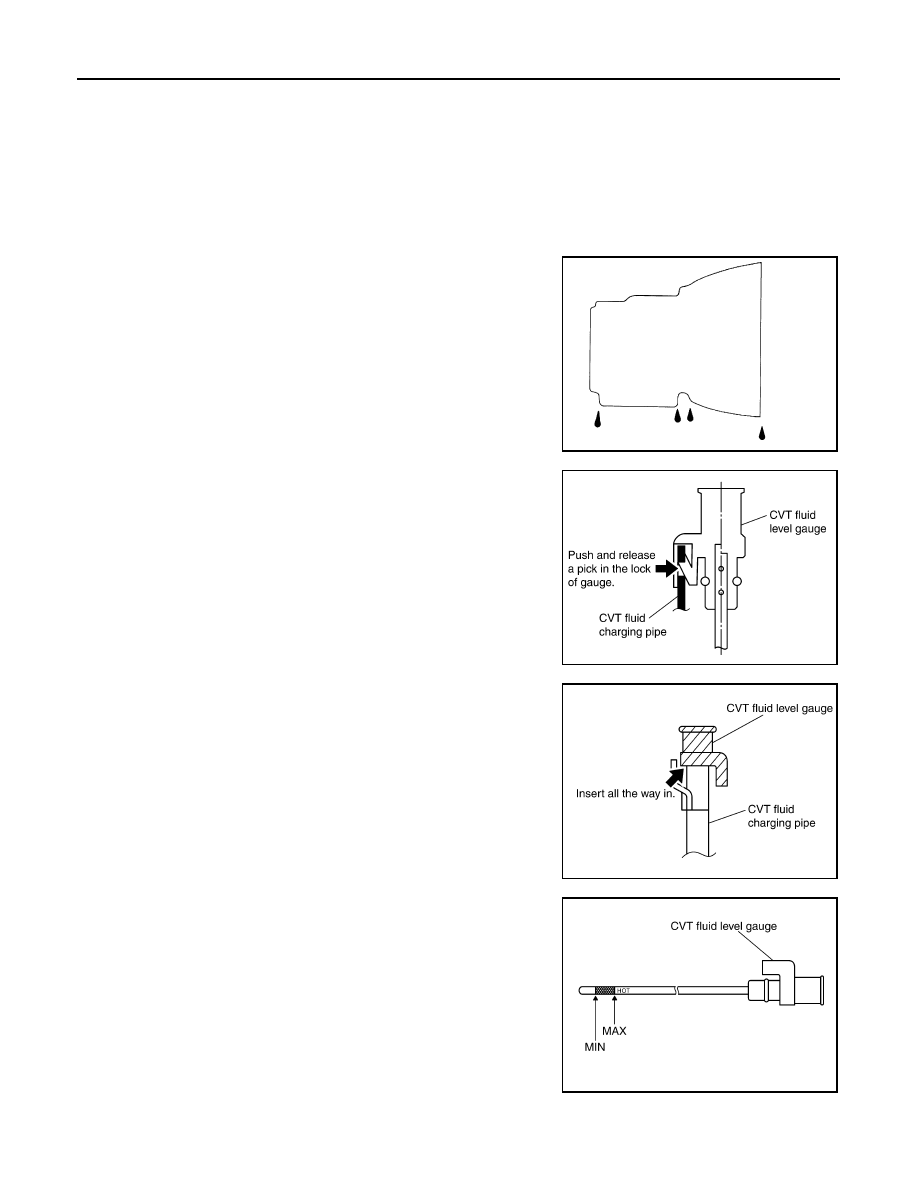

1. Check for fluid leakage.

2. With the engine warmed up, drive the vehicle in an urban area.

When ambient temperature is 20

°C (68°F), it takes about 10

minutes for the CVT fluid to warm up to 50

° to 80°C (122° to

176

°F).

3. Park the vehicle on a level surface.

4. Apply parking brake firmly.

5. With engine at idle, while depressing brake pedal, move shift

selector throughout the entire shift range.

6. Pull out the CVT fluid level gauge from the CVT fluid charging

pipe after pressing the tab on the CVT fluid level gauge to

release the lock.

7. Wipe fluid off the CVT fluid level gauge. Insert the CVT fluid

level gauge rotating 180

° from the originally installed position,

then securely push the CVT fluid level gauge until it meets the

top end of the CVT fluid charging pipe.

CAUTION:

When wiping away the CVT fluid level gauge, always use

lint-free paper, not a cloth rag.

8. Place the selector lever in “P” or “N” and make sure the fluid

level is within the specified range.

CAUTION:

When reinstalling CVT fluid level gauge, insert it into the

CVT fluid charging pipe and rotate it to the original installa-

tion position until it is securely locked.

CVT FLUID CONDITION

SMA146B

SCIA1933E

SCIA1931E

SCIA1932E