Nissan Titan A60. Manual - part 711

MA-24

< PERIODIC MAINTENANCE >

RECOMMENDED FLUIDS AND LUBRICANTS

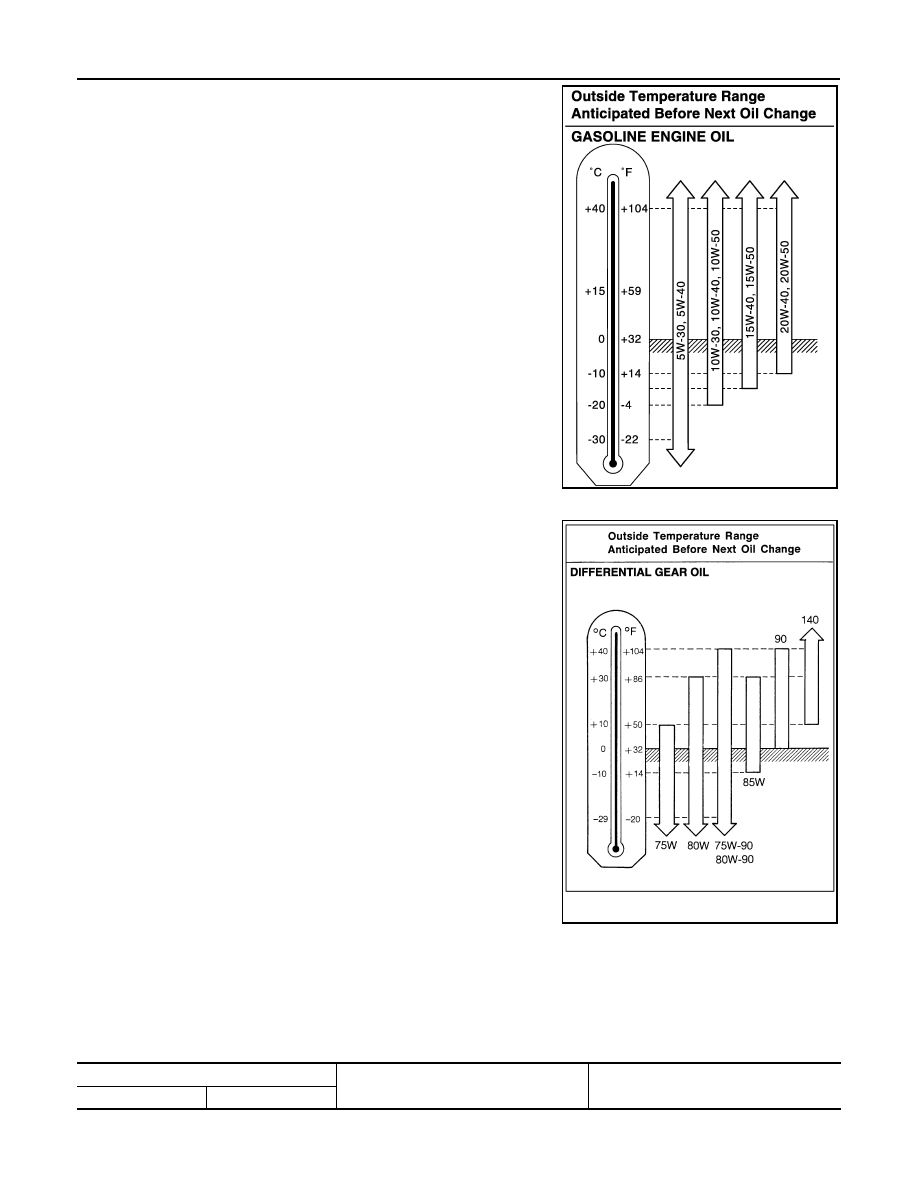

• 10W-30 is preferable.

5W-30 is also preferable and will improve fuel economy.

If 10W-30 or 5W-30 is not available, select the viscosity from the

chart, that is suitable for the outside temperature range.

DIFFERENTIAL GEAR OIL

• 80W-90 for the front differential gear is preferable.

FOR MEXICO : Engine Coolant Mixture Ratio

INFOID:0000000006751591

MIXTURE RATIO

The engine cooling system is filled at the factory with a high-quality, year-round, anti-freeze coolant solution.

The anti-freeze solution contains rust and corrosion inhibitors. Therefore, additional cooling system additives

are not necessary.

JPPIA0003GB

JPPIA0001GB

Protection for outside temperature down to:

Genuine NISSAN Engine Coolant or equiv-

alent

Demineralized water or distilled water

°C

°F