Nissan Titan A60. Manual - part 705

LU-18

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and Limit

INFOID:0000000006158412

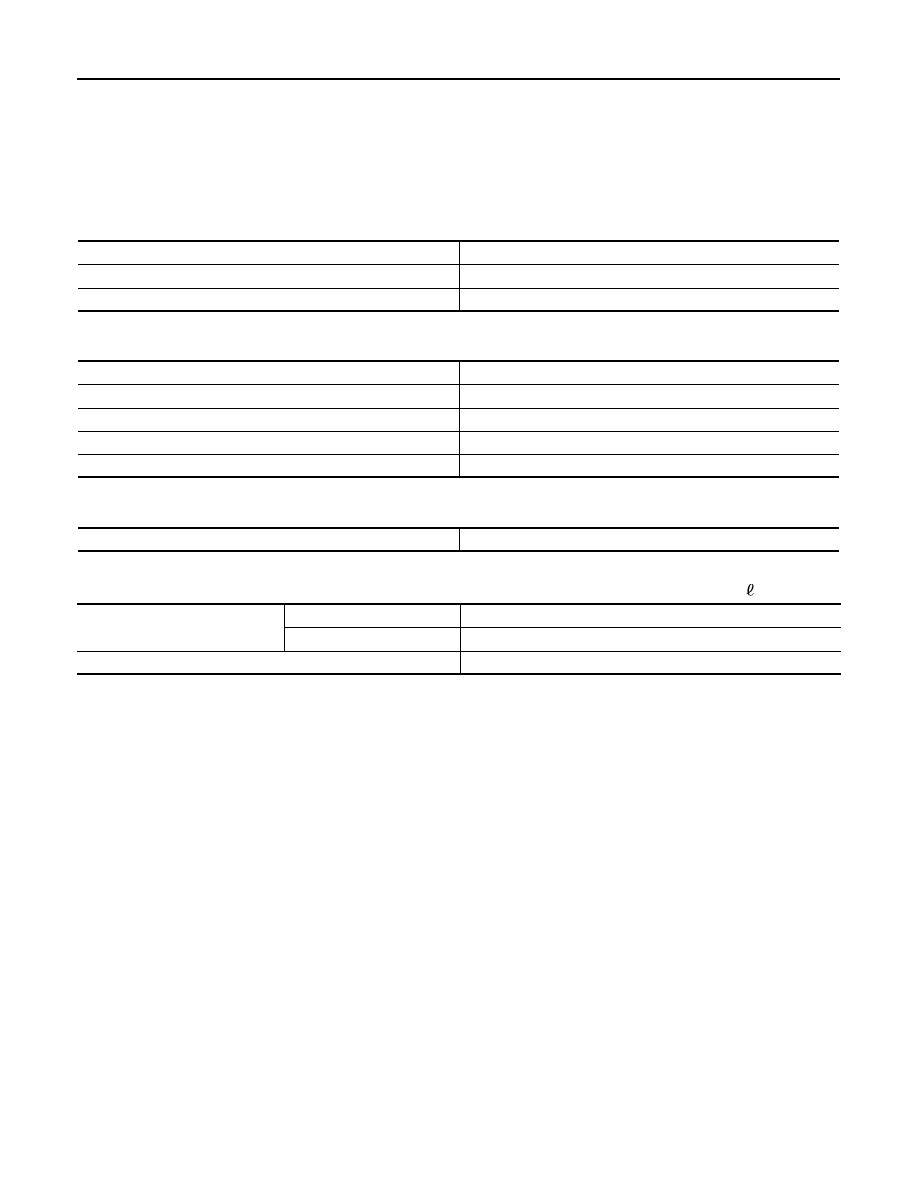

OIL PRESSURE

Unit: kPa (kg/cm

2, psi)

OIL PUMP

Unit: mm (in)

REGULATOR VALVE

Unit: mm (in)

ENGINE OIL CAPACITY (APPROXIMATE)

Unit: (US qt, Imp qt)

Engine speed

Approximate discharge oil pressure

Idle speed

More than 98 (1.0, 14)

2,000 rpm

More than 294 (3.0, 43)

Body to outer rotor radial clearance

0.114 - 0.200 (0.0045 - 0.0079)

Inner rotor to outer rotor tip clearance

Below 0.180 (0.0071)

Body to inner rotor side clearance

0.030 - 0.070 (0.0012 - 0.0028)

Body to outer rotor side clearance

0.030 - 0.090 (0.0012 - 0.0035)

Inner rotor to brazed portion of housing clearance

0.045 - 0.091 (0.0018 - 0.0036)

Regulator valve to oil pump cover clearance

0.040 - 0.097 (0.0016 - 0.0038)

Drain and refill

With oil filter change

6.5 (6 7/8, 5 3/4)

Without oil filter change

6.2 (6 1/2, 5 1/2)

Dry engine (engine overhaul)

7.6 (8, 6 3/4)