Nissan Titan A60. Manual - part 495

POWER SUPPLY AND GROUND CIRCUIT

EXL-35

< DTC/CIRCUIT DIAGNOSIS >

C

D

E

F

G

H

I

J

K

M

A

B

EXL

N

O

P

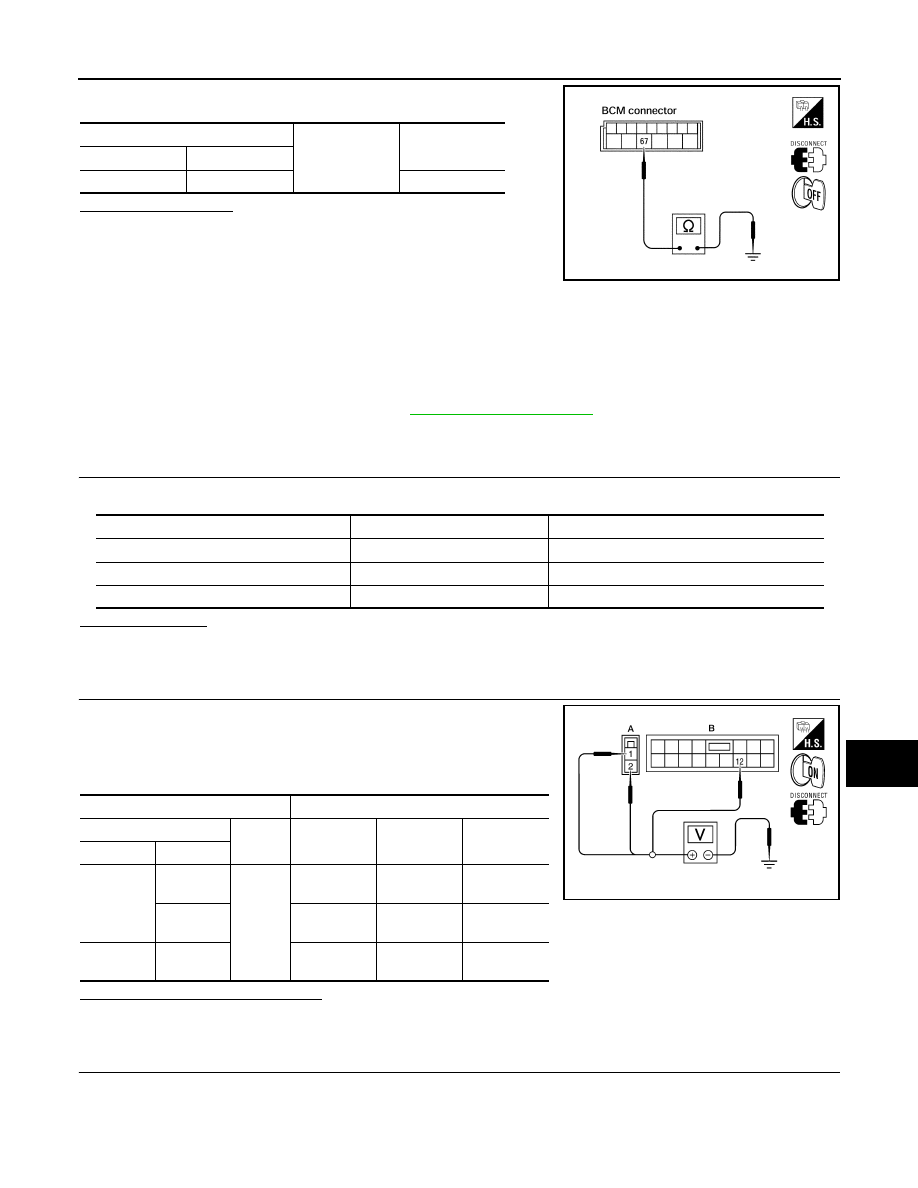

Check continuity between BCM harness connector and ground.

Does continuity exist?

YES

>> Inspection End.

NO

>> Repair or replace harness.

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM) : Di-

agnosis Procedure

INFOID:0000000006607775

Regarding Wiring Diagram information, refer to

.

1.

CHECK FUSES AND FUSIBLE LINK

Check that the following IPDM E/R fuses or fusible link are not blown.

Is the fuse blown?

YES

>> Replace the blown fuse or fusible link after repairing the affected circuit.

NO

>> GO TO 2

2.

CHECK BATTERY POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R.

3. Check voltage between IPDM E/R harness connectors and

ground.

Is the measurement value normal?

YES

>> GO TO 3

NO

>> Repair or replace harness.

3.

CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

BCM

Ground

Continuity

Connector

Terminal

M20

67

Yes

LIIA0915E

Terminal No.

Signal name

Fuses and fusible link No.

1

Battery

A (140A), D (80A)

2

Battery

C (80A)

12

Ignition switch ON or START

59 (10A)

Terminals

Ignition switch position

(+)

(

−)

OFF

ON

START

Connector

Terminal

E118 (A)

1

Ground

Battery

voltage

Battery

voltage

Battery

voltage

2

Battery

voltage

Battery

voltage

Battery

voltage

E119 (B)

12

0V

Battery

voltage

Battery

voltage

AWMIA0023ZZ