Nissan Titan A60. Manual - part 494

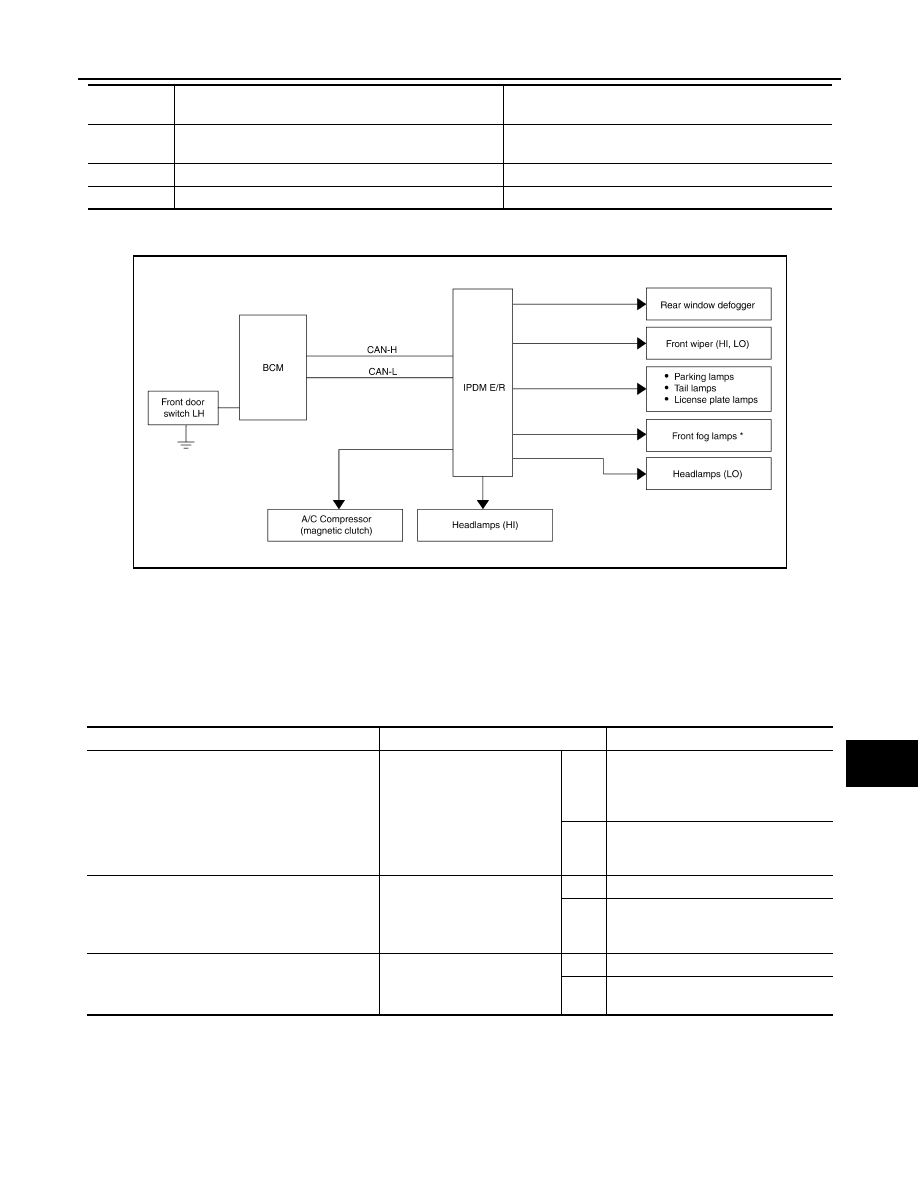

DIAGNOSIS SYSTEM (IPDM E/R)

EXL-31

< SYSTEM DESCRIPTION >

C

D

E

F

G

H

I

J

K

M

A

B

EXL

N

O

P

Concept of auto active test

• IPDM E/R starts the auto active test with the door switch signals transmitted by BCM via CAN communica-

tion. Therefore, the CAN communication line between IPDM E/R and BCM is considered normal if the auto

active test starts successfully.

• The auto active test facilitates troubleshooting if any systems controlled by IPDM E/R cannot be operated.

Diagnosis chart in auto active test mode

3

Tail, license, parking lamps and front fog lamps (if

equipped)

10 seconds

4

Headlamps

LO for 10 seconds

→ HI on-off for 5 seconds

5

A/C compressor (magnetic clutch)

ON

⇔ OFF 5 times

Operation

sequence

Inspection Location

Operation

*: If equipped

AWMIA1108GB

Symptom

Inspection contents

Possible cause

Oil pressure low/coolant temperature high warning

indicator does not operate

Perform auto active test.

Does the oil pressure low/

coolant temperature high

warning indicator operate?

YES

• IPDM E/R signal input circuit

• ECM signal input circuit

• CAN communication signal be-

tween ECM and combination meter

NO

CAN communication signal between

IPDM E/R, BCM and combination

meter

Oil pressure gauge does not operate

Perform auto active test.

Does the oil pressure gauge

operate?

YES

IPDM E/R signal input circuit

NO

CAN communication signal between

IPDM E/R, BCM and combination

meter

Rear window defogger does not operate

Perform auto active test.

Does the rear window defog-

ger operate?

YES

BCM signal input circuit

NO

CAN communication signal between

BCM and IPDM E/R